china disc spring washer dimensions

Understanding China Disc Spring Washer Dimensions

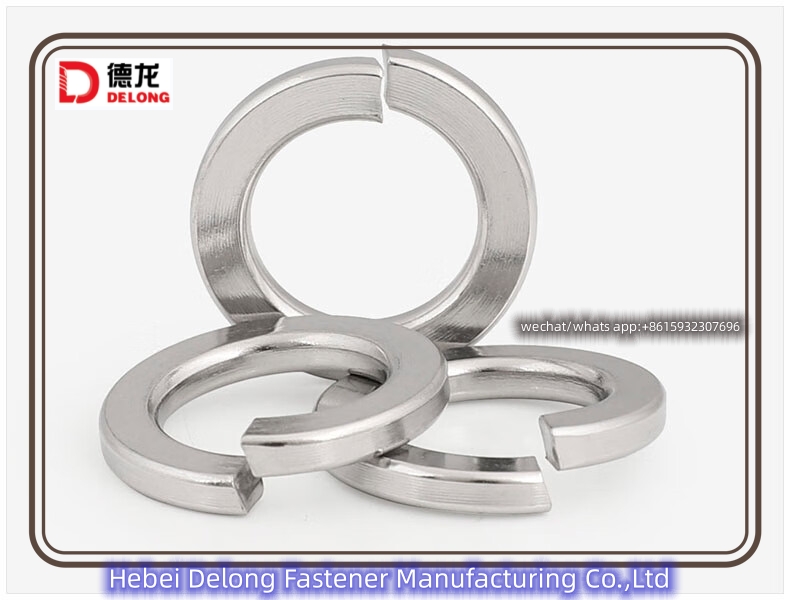

Disc spring washers, also known as Belleville washers, are widely used in various industrial applications for providing preload and absorbing shock. Their unique design allows them to effectively maintain tension in bolted joints and prevent loosening due to vibrations. The dimensions of these washers play a critical role in their performance, especially in high-stress environments.

In China, the manufacturing of disc spring washers adheres to several standards, ensuring consistency and reliability across various applications. The dimensions of these washers typically include the outer diameter (OD), inner diameter (ID), thickness (t), and the spring rate, which defines the stiffness of the washer. When selecting a disc spring washer, engineers must consider these dimensions alongside the specific requirements of their applications.

The outer diameter generally ranges from a few millimeters to several inches, depending on the size and type of the assembly where it will be used. The inner diameter is typically smaller than the outer diameter and is designed to fit snugly around a bolt or a shaft, ensuring that the washer properly seats itself and performs its function without slipping. The thickness of the washer is crucial as it determines the load capacity and deflection characteristics of the component. A thicker washer can handle greater loads but may also require more space, which can be a consideration in compact designs.

china disc spring washer dimensions

Spring rate, measured in Newtons per millimeter (N/mm), indicates how much force is needed to compress the washer a certain distance. The higher the spring rate, the stiffer the washer. This characteristic is essential in applications where maintaining a specific load is necessary.

China's disc spring washers come in various grades and materials, often made from stainless steel, carbon steel, or alloy steel, which influences their strength and resistance to corrosion. Depending on the application, engineers may choose washers that offer specific properties, like high-temperature resistance or enhanced fatigue life.

Furthermore, manufacturers often provide detailed technical specifications, including load vs. deflection curves, which help engineers determine the appropriate washer for their needs. These curves allow for optimization in design, ensuring that the end product can withstand the operational demands it will face.

In summary, when considering disc spring washer dimensions in the context of Chinese manufacturing, one must pay close attention to the outer and inner diameters, thickness, and spring rate. Understanding these parameters enables engineers and designers to choose the right washer for their specific applications, enhancing the reliability and performance of their mechanical assemblies. As industries continue to evolve, the role of high-quality disc spring washers remains pivotal in ensuring the longevity and effectiveness of machinery across various sectors.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024