China 1 4 2020 Self Tapping Screw Specifications and Applications Guide

Understanding China’s Self-Tapping Screws A Comprehensive Overview

In recent years, China has established itself as a leading manufacturer of various hardware components, including self-tapping screws. These screws are vital in numerous industries ranging from construction to electronics, where they provide the necessary fastening solution without the need for pre-drilled holes. This article delves into the significance of self-tapping screws, their types, and their applications, particularly focusing on the manufacturing capabilities in China.

What Are Self-Tapping Screws?

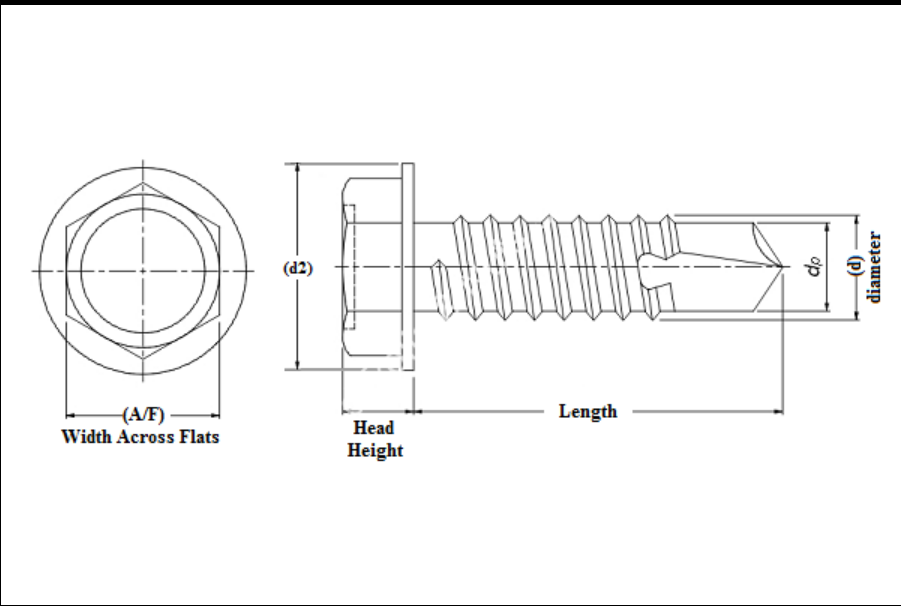

Self-tapping screws are uniquely designed to create their own holes as they are driven into materials, making them an essential fastener in many mechanical and construction applications. They feature a sharp point and typically possess a thread that can cut into a material, such as metal, wood, or plastic. This means that they can be used in a variety of situations where traditional screws would require pre-drilling, enhancing efficiency and convenience.

Types of Self-Tapping Screws

There are several types of self-tapping screws, each tailored for specific applications

. The most common types include1. Thread Cutting Screws These screws are used when the material into which they are being inserted is softer than the screw itself. They cut their own threads into the material for a secure fit.

2. Thread Forming Screws Designed for use in harder materials, these screws deform the material to create a thread, making them ideal for applications in plastics or thin sheet metals.

3. Metal Screws These are made from hardened materials and are primarily used in metal-to-metal applications, providing strong connections.

china 1 4 20 self tapping screw

4. Wood Screws With coarse threads, these screws are designed for wooden materials and are often used in furniture manufacturing and construction.

China’s Role in Self-Tapping Screw Production

China has become a global powerhouse in the manufacturing of self-tapping screws, primarily due to its robust industrial base, advanced manufacturing technologies, and competitive pricing. Chinese manufacturers leverage economies of scale, allowing them to produce high volumes of screws at a lower cost compared to their international counterparts. This capability has made them suppliers of choice for many companies around the world.

Moreover, China's commitment to improving quality standards through modern factories and stringent quality control processes ensures that the screws produced meet international specifications. Many manufacturers have invested in research and development to produce innovative variations of self-tapping screws that can cater to specific industry needs.

Applications of Self-Tapping Screws

The applications of self-tapping screws are virtually limitless. They are critical in the automotive industry for assembling various components, in electronics for securing circuit boards, and in construction for joining structural elements. Their versatility also makes them popular in the household, from furniture assembly to DIY projects.

The demand for these fasteners continues to grow, driven by the increasing need for efficient and reliable fastening solutions across multiple sectors. As the construction and automotive industries expand, so does the need for high-quality self-tapping screws, further solidifying China’s position as a leader in this niche market.

Conclusion

In conclusion, self-tapping screws are an essential component in a myriad of industries, providing efficiency and reliability in their applications. With China's vast manufacturing capabilities and commitment to quality, the country remains a fundamental player in supplying these crucial fasteners to the global market. As industries evolve, the demand for innovative fastening solutions will likely continue, reinforcing the significance of self-tapping screws manufactured in China.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024