China Flat Washer Dimensions and Specifications Guide for Various Applications

Understanding Flat Washer Sizes in China A Comprehensive Guide

Flat washers, also known simply as washers, are small but critical components used in a wide range of applications, from construction to manufacturing and automotive industries. Their primary function is to distribute the load of a threaded fastener, such as a bolt or screw, and prevent damage to the surface being fastened. In China, where manufacturing capabilities are vast and diverse, understanding the sizing standards for flat washers is essential for businesses that source these components.

The Importance of Choosing the Right Size

Choosing the correct size of flat washers is vital for ensuring the structural integrity and longevity of the assembly. A washer that is too small may not provide adequate support, leading to failure, while one that is too large can create unnecessary bulk and make assembly challenging. In industrial applications, even slight discrepancies in size can have significant ramifications. Therefore, it's crucial to understand the various measurements and standards used in China for flat washers.

Standard Sizes and Measurements

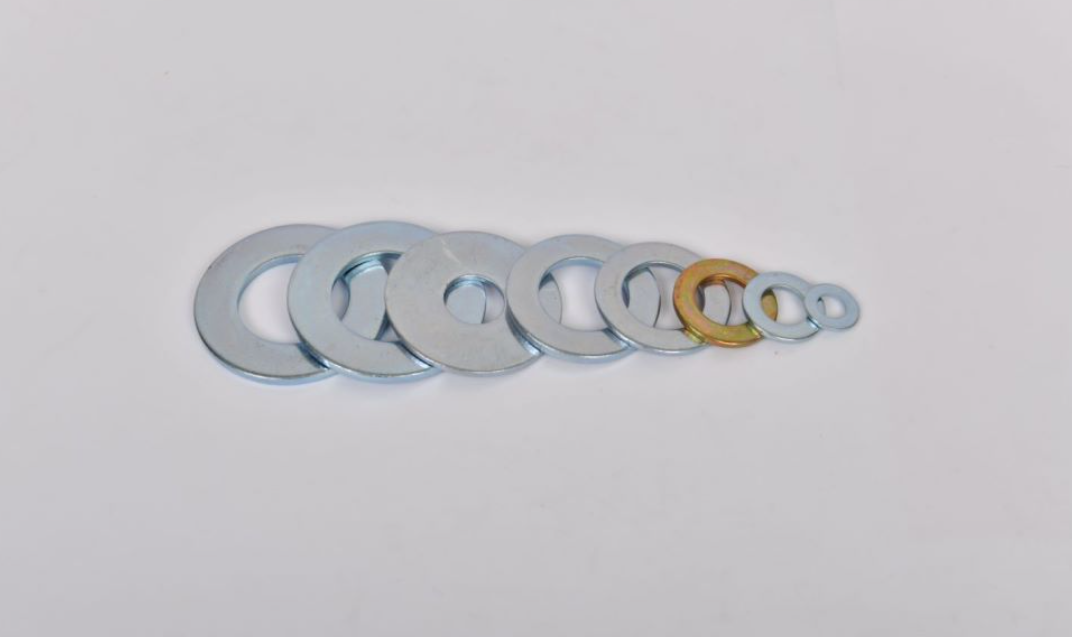

Flat washers are generally characterized by their outer diameter (OD), inner diameter (ID), and thickness. In China, the standard sizes often conform to the metric system. Common inner diameters include sizes like 3mm, 4mm, 5mm, and so forth, while outer diameters can vary significantly, typically ranging from 6mm up to 100mm and beyond, depending on the application.

A standard flat washer often adheres to the ISO 7089 specification, which dictates the thickness and dimensions based on the size of the fastener being used. For example, a washer designated for an M6 bolt might have an outer diameter of around 12mm, an inner diameter of 6mm, and a thickness of approximately 1-2mm. Some manufacturers also adhere to the ASTM standards, which may have slight variations in size specifications, making it essential for buyers to communicate clearly about required standards when sourcing.

china flat washer size

Materials and Coatings

Besides size, material selection is another critical factor. Flat washers can be made from various materials, including steel, stainless steel, plastic, and rubber. The choice of material often depends on the environmental conditions to which the washer will be exposed, as well as the load it must bear. For instance, stainless steel washers are preferred in outdoor or corrosive environments due to their excellent resistance to rust and degradation.

Additionally, washers can be coated to enhance their durability and corrosion resistance. Common coatings include zinc plating, which provides a layer of protection against rust, and various treatments that can enhance wear resistance.

Purchasing Flat Washers in China

For businesses looking to source flat washers from China, numerous manufacturers and suppliers specialize in these components. It is advisable to research and verify the credibility of the suppliers and request specifications, samples, and certifications to ensure quality and adherence to standards. Trade shows, online B2B marketplaces, and industry networks are valuable resources for identifying reputable manufacturers.

Conclusion

Understanding flat washer sizes and standards in China can significantly impact the efficiency and safety of various applications. Whether you are involved in manufacturing, construction, or maintenance, selecting the right flat washers—according to size, material, and coating—is paramount for achieving optimal performance and durability in your projects. By equipping yourself with the necessary knowledge and resources, you can make informed decisions and foster successful partnerships in the fast-paced world of industrial supply.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024