cheap self tapping sheet metal screw

The Importance of Cheap Self-Tapping Sheet Metal Screws in Modern Applications

In today's world, where efficiency and cost-effectiveness are crucial in construction and manufacturing, the importance of good quality fasteners cannot be understated. Among these fasteners, self-tapping sheet metal screws play a vital role in various applications due to their unique design and functionality. The emergence of affordable options in this category, often referred to as cheap self-tapping sheet metal screws, has made them even more accessible for DIY enthusiasts, contractors, and large-scale builders alike.

Understanding Self-Tapping Screws

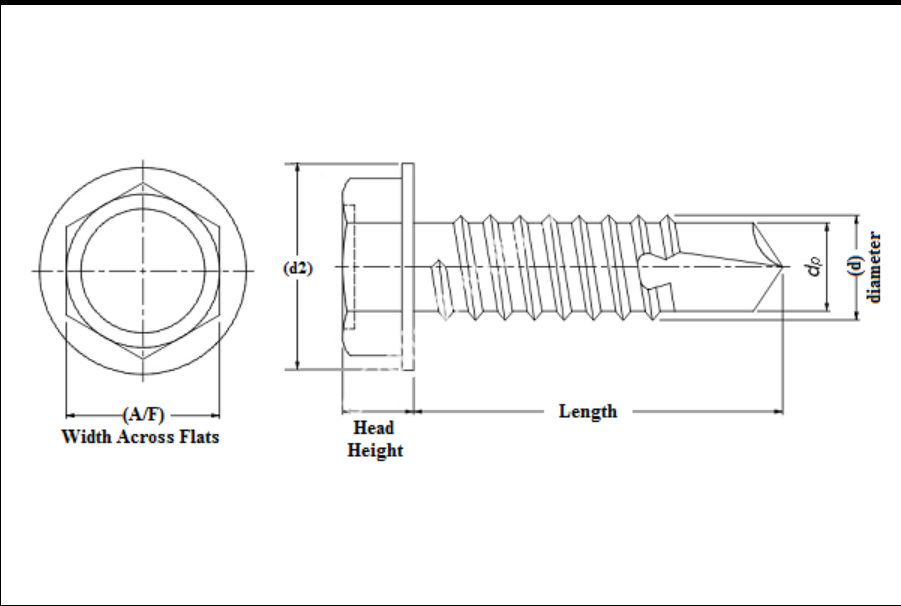

Self-tapping screws are a specific type of screw that, as the name suggests, can create their own hole while being driven into materials. Made primarily from durable materials such as steel, stainless steel, or brass, these screws are characterized by their sharp, cutting threads, which enable them to penetrate sheet metal swiftly. Unlike traditional screws, which require a pre-drilled hole, self-tapping screws simplify the assembly process, saving both time and labor costs.

The Rise of Affordable Options

The phrase cheap self-tapping sheet metal screws might evoke concerns about quality, but it doesn't have to. The rise in manufacturing techniques and the global market for fasteners have led to an influx of affordable self-tapping screws that maintain adequate durability and reliability. Cheap does not necessarily mean substandard; many manufacturers have adopted stringent quality control measures to ensure that even their low-cost products are effective and safe for use.

Applications in Various Industries

One of the most significant advantages of self-tapping screws is their versatility. They are widely used in various industries, including construction, automotive, and electronics. In construction, for instance, these screws are commonly used for securing metal sheets, frames, and other components, facilitating rapid assembly and disassembly. In the automotive industry, they are employed in the assembly of vehicles where lightweight materials need to be fastened securely without the risk of looseness over time.

For electronics, self-tapping screws provide a low-profile solution for securing components within devices. Their ability to pierce through metal without damaging the surrounding area makes them an ideal choice for delicate projects, ensuring both stability and aesthetic appeal.

Benefits of Using Cheap Self-Tapping Screws

cheap self tapping sheet metal screw

1. Cost-Effectiveness The primary advantage of cheap self-tapping screws is their affordability. They can significantly reduce project costs, making them a popular choice for both small and large-scale applications.

2. Time-Saving The self-tapping feature eliminates the need for pre-drilling holes, allowing for faster assembly and improved productivity on job sites.

3. Ease of Use Ideal for DIY projects, these screws can be driven into materials using a simple power drill, making them accessible for individuals without advanced tools or experience.

4. Durability Many affordable self-tapping screws are made with corrosion-resistant coatings, ensuring longevity even in harsh environments.

5. Wide Availability Because of their popularity, cheap self-tapping screws are easily found in hardware stores and online, making it convenient to source them for any project.

Choosing the Right Self-Tapping Screws

When selecting self-tapping screws, one should consider factors such as the material of the sheets being fastened, the load requirements, and environmental conditions. While seeking inexpensive options, it is essential to balance cost with quality. Thoroughly reviewing product specifications, customer reviews, and manufacturer reputation can lead to the right choice for your needs.

Conclusion

In conclusion, cheap self-tapping sheet metal screws represent an essential tool in modern construction and manufacturing. Their cost-effectiveness, versatility, and ease of use make them an invaluable resource for both professionals and DIY enthusiasts. As technology continues to evolve, we can expect improvements in the production and quality of these screws, cementing their place as a staple fastener in various applications. Adopting them not only improves the efficiency of projects but also encourages a broader audience to engage in construction and repair activities.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024