buy hardened flat washer dimensions

When it comes to fasteners and hardware, flat washers play a crucial role in enhancing the performance and reliability of various applications, especially in construction and manufacturing. Among the different types available, hardened flat washers are particularly noteworthy due to their durability and strength. In this article, we will explore the dimensions, applications, and benefits of using hardened flat washers, guiding you on why they are an essential choice for your projects.

Hardened flat washers are specifically designed to distribute the load of a threaded fastener, such as a bolt or screw, over a larger surface area. This helps to prevent damage to the material being fastened, reducing the risk of material deformation and wear. The hardened designation means that these washers undergo a heat treatment process that increases their hardness, making them ideal for high-stress applications.

Dimensions of Hardened Flat Washers

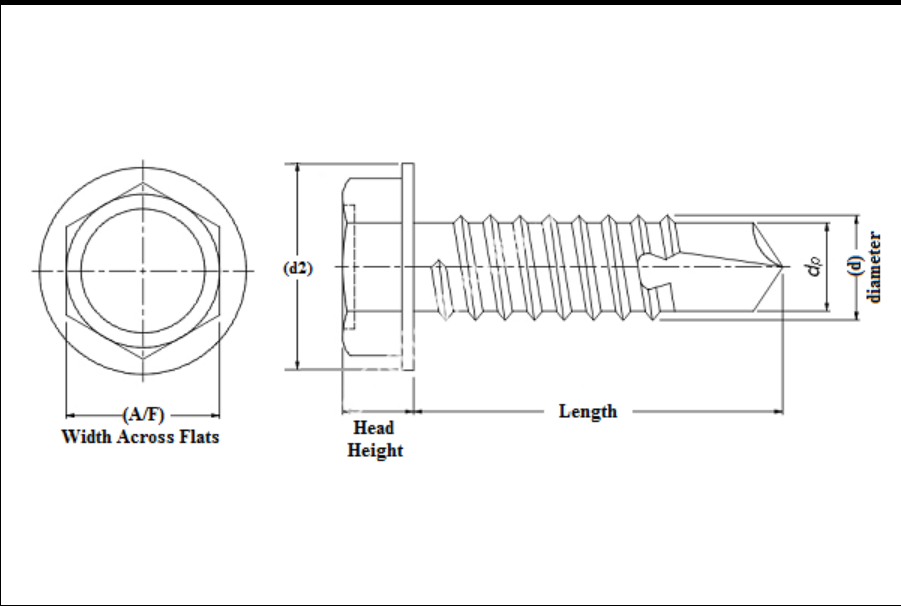

When selecting hardened flat washers, it is essential to consider their dimensions, as they must match the specifications of the fasteners and the materials they will be used with. The key dimensions of a flat washer commonly include

1. Outer Diameter (OD) The total width of the washer from one outer edge to the other. This dimension is crucial as it dictates how much surface area the washer will cover and thus how effectively it will distribute the load.

2. Inner Diameter (ID) This dimension corresponds to the hole in the center of the washer, which must fit snugly around the bolt or screw. The inner diameter must be slightly larger than the bolt diameter to allow for easy installation but should not be excessively loose.

3. Thickness This measurement is the height of the washer itself. Thicker washers provide more support and stability, while thinner washers are generally easier to use and can be sufficient for lighter applications.

Applications of Hardened Flat Washers

Hardened flat washers are prevalent in various applications due to their strength and durability. Common industries that utilize these washers include

buy hardened flat washer dimensions

- Construction Used in framing, roofing, and foundations where metal and wood connections are critical for structural integrity.

- Automotive Found in various parts of vehicles, these washers assist in securing components while enduring vibrations and demanding conditions

.- Manufacturing In machinery and equipment assembly, hardened flat washers help maintain connection stability, especially in high-pressure environments.

Benefits of Using Hardened Flat Washers

1. Strength and Durability The heat treatment process used for hardened washers increases their resistance to wear and deformation, making them suitable for heavy-duty and high-load applications.

2. Load Distribution By spreading the load from fasteners across a larger area, these washers minimize the risk of material failure, enhancing the longevity and reliability of structures or machinery.

3. Corrosion Resistance Many hardened flat washers are available with protective coatings, making them resistant to rust and corrosion, an essential feature when used in outdoor or wet environments.

Conclusion

In conclusion, when you're looking to buy hardened flat washers, understanding their dimensions and applications ensures you make an informed choice that guarantees the effectiveness and longevity of your projects. These small yet powerful components are vital in ensuring the strength and stability of countless applications, making them indispensable in various industries. Always ensure to select the right dimensions and types for your specific needs to maximize their potential.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024