Brass Spring Washer Manufacturer for Reliable Industrial Solutions and Quality Products

The Importance of Brass Spring Washers in Industrial Applications

Brass spring washers are essential components in various industrial applications, providing vital functions that ensure stability, reliability, and durability in mechanical assemblies. With their unique physical properties, brass spring washers have become a popular choice in numerous sectors, including automotive, aerospace, electronics, and construction.

What are Brass Spring Washers?

Brass spring washers are flat, circular components with a central hole, designed to provide a spring-like effect when compressed. Made from brass, an alloy of copper and zinc, these washers exhibit excellent corrosion resistance, making them suitable for use in environments where moisture and chemicals may be present. Their natural elasticity allows them to maintain pressure and tension, which is critical in preventing loosening of bolts and screws over time.

Key Benefits of Brass Spring Washers

1. Corrosion Resistance Brass inherently resists rust and corrosion, which extends the lifespan of mechanical assemblies across various applications. This makes them ideal for outdoor settings and industries where exposure to moisture is a concern.

2. Enhanced Load Distribution The design of spring washers helps distribute load evenly across the surface they are attached to. This distribution reduces the risk of damage to both the bolt and the material being fastened, ensuring a more secure assembly.

3. Vibration Dampening In applications where machinery operates under constant movement, vibrations can lead to loosening of fasteners. Brass spring washers counteract these vibrations, maintaining tension and preventing loosening over time. This function is particularly crucial in automotive and aerospace applications, where safety is paramount.

4. Easy Installation Brass spring washers are straightforward to install, requiring minimal tools. Their compatibility with various bolt sizes makes them versatile in a wide array of applications, simplifying inventory management for manufacturers and engineers.

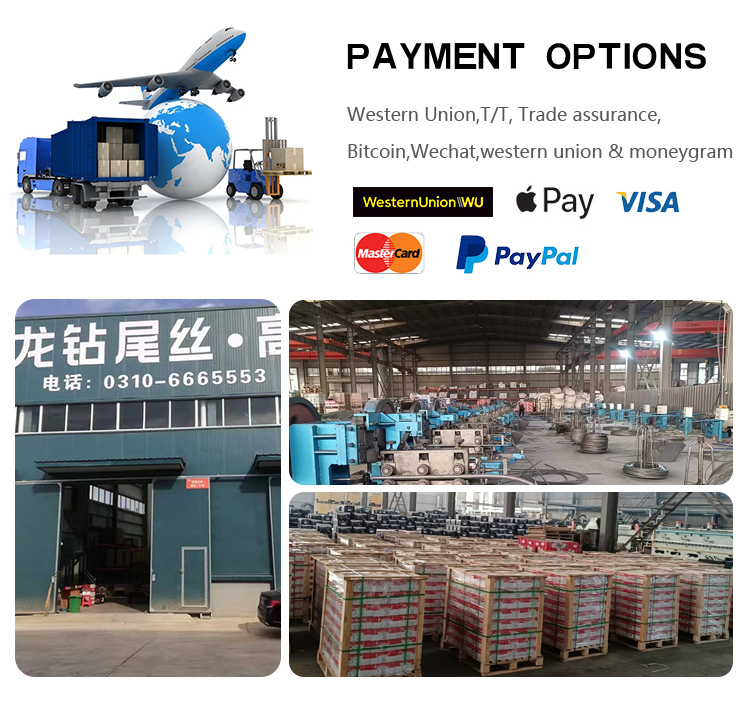

brass spring washer company

5. Aesthetic Appeal The attractive golden hue of brass can also be a factor in design considerations. For applications where components may be visible, the aesthetic appeal of brass spring washers can enhance the overall appearance of the product.

Applications of Brass Spring Washers

Brass spring washers are utilized in diverse industries

- Automotive Industry They play a critical role in the assembly of engines, chassis, and other vital components, where they support tension and help mitigate wear over time.

- Aerospace Sector With rigorous safety standards, the aerospace industry relies on the reliability of brass spring washers in maintaining the integrity of assemblies in aircraft and spacecraft.

- Electronics In electronic devices, these washers help secure components in place while preventing vibration-related issues that could lead to malfunction.

- Construction Used in various building applications, brass spring washers ensure that fastenings remain secure even under significant stress or environmental changes.

Conclusion

In conclusion, brass spring washers are vital components in many industrial applications due to their durability, corrosion resistance, and ability to maintain tension over time. Their unique properties make them indispensable in ensuring the reliability and safety of mechanical assemblies across various sectors. As industries continue to evolve and innovate, the importance of high-quality components like brass spring washers will only grow, paving the way for safer and more efficient technologies in the future. Selecting the right brass spring washer for specific applications can greatly impact overall performance and longevity, making it crucial for engineers and manufacturers to prioritize quality in their procurement processes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024