Feb . 20, 2025 00:49

Back to list

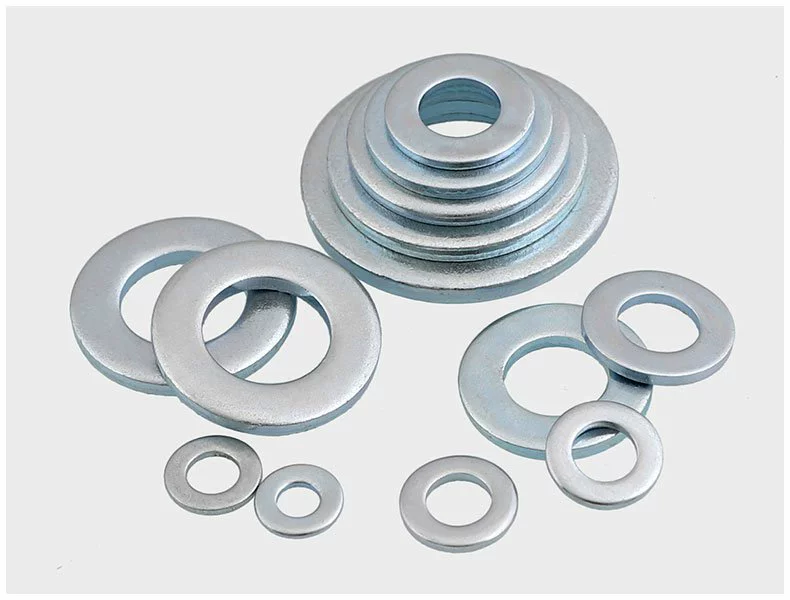

bowed spring washer

In the realm of industrial applications, the bowed spring washer stands out as an essential component, known for its ability to provide tension and absorb vibrations in mechanical assemblies. This unique washer shape is not just a random design, but a result of meticulous engineering to enhance performance in various applications.

For professionals in the field, the historical development and evolutionary innovations in bowed spring washer design cannot be overlooked. Initially conceived to address the inadequacies of traditional flat washers, ongoing research has continued to refine their design for expanded uses. Today's sophisticated computational modeling allows for the simulation of stress and load distribution, ensuring the washers meet the rigorous demands of modern engineering projects. Trust in the performance and reliability of bowed spring washers is further solidified through established manufacturing standards. Reputable manufacturers adhere to globally recognized standards such as the ISO and DIN, ensuring that each washer meets stringent criteria for dimension, quality, and load capability. This standardization guarantees consistency in performance, providing engineers with confidence that components will function as intended under diverse conditions. For product users, it's crucial to discern authentic quality when sourcing these washers. Counterfeit or sub-standard products can lead to catastrophic failures. Hence, collaborating with trusted suppliers who provide verified products backed by warranties and customer support is essential. This not only ensures peace of mind but also safeguards the integrity of the entire mechanical assembly. Incorporating bowed spring washers into an assembly not only enhances mechanical stability but also demonstrates a commitment to utilizing advanced engineering solutions for optimal performance. Each application, while unique, benefits from the universal properties of tension maintenance and vibration resistance that these washers offer. As innovations continue to push the boundaries of what's possible in mechanical design, the bowed spring washer remains a testament to engineering ingenuity—a small component with an immense impact.

For professionals in the field, the historical development and evolutionary innovations in bowed spring washer design cannot be overlooked. Initially conceived to address the inadequacies of traditional flat washers, ongoing research has continued to refine their design for expanded uses. Today's sophisticated computational modeling allows for the simulation of stress and load distribution, ensuring the washers meet the rigorous demands of modern engineering projects. Trust in the performance and reliability of bowed spring washers is further solidified through established manufacturing standards. Reputable manufacturers adhere to globally recognized standards such as the ISO and DIN, ensuring that each washer meets stringent criteria for dimension, quality, and load capability. This standardization guarantees consistency in performance, providing engineers with confidence that components will function as intended under diverse conditions. For product users, it's crucial to discern authentic quality when sourcing these washers. Counterfeit or sub-standard products can lead to catastrophic failures. Hence, collaborating with trusted suppliers who provide verified products backed by warranties and customer support is essential. This not only ensures peace of mind but also safeguards the integrity of the entire mechanical assembly. Incorporating bowed spring washers into an assembly not only enhances mechanical stability but also demonstrates a commitment to utilizing advanced engineering solutions for optimal performance. Each application, while unique, benefits from the universal properties of tension maintenance and vibration resistance that these washers offer. As innovations continue to push the boundaries of what's possible in mechanical design, the bowed spring washer remains a testament to engineering ingenuity—a small component with an immense impact.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News