best spring washer with flat washer

The Best Spring Washer with Flat Washer A Comprehensive Guide

When it comes to ensuring the integrity and longevity of mechanical assemblies, choosing the right fasteners is crucial. Among the various types of washers available, spring washers and flat washers play unique roles in providing stability, distributing loads, and preventing loosening of structures. In this article, we will explore the benefits of using spring washers in conjunction with flat washers, and identify the best combinations for your engineering needs.

Understanding Washers Spring vs. Flat

Before diving into the best combinations, it's essential to understand the distinctive features of spring and flat washers.

Flat Washers These washers are thin, flat disks made typically from metal, although plastic versions exist for specific applications. Their primary purpose is to distribute the load of a threaded fastener, preventing damage to the surface of the materials being joined. They also serve to increase the friction between the fastener and the materials, which helps prevent loosening over time.

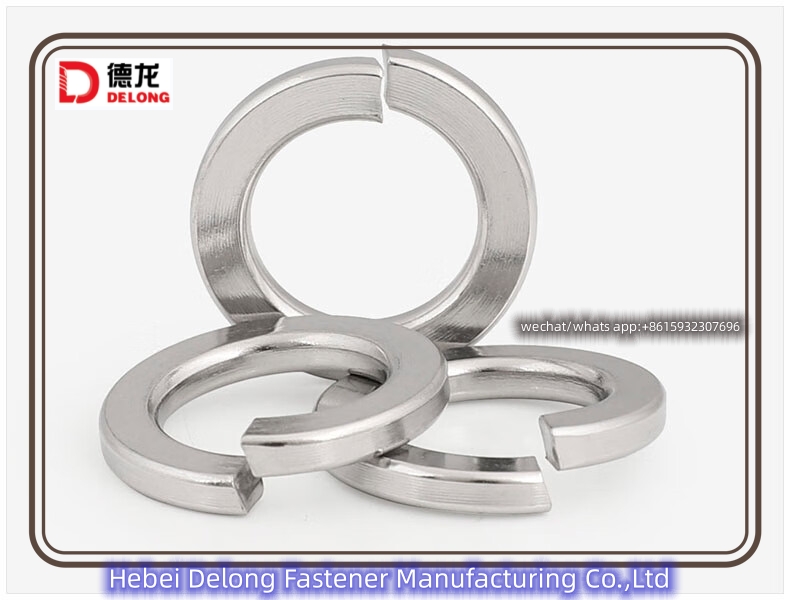

Spring Washers These washers, often conical in shape, are designed to absorb shock and maintain tension in a joint. Their unique design allows them to exert a constant force even as the fastener experiences changes in load, temperature, or vibration. This characteristic makes spring washers ideal for dynamic applications where the assembly is subject to movements or vibrations.

The Synergy of Spring and Flat Washers

Using spring washers in combination with flat washers can optimize the performance of a bolted joint. The flat washer lays flat against the surface of the materials being fastened, providing a stable base that supports the load. Meanwhile, the spring washer works to compensate for any potential relaxation or settling that might occur due to vibrations or thermal expansion. Together, they create a robust fastening system that enhances both safety and durability.

best spring washer with flat washer

Choosing the Best Spring and Flat Washer Combination

The selection of the appropriate washers depends on several factors, including the materials being joined, the load requirements, and environmental conditions. Here are a few combinations that are widely recognized as the best choices in various applications

1. Industrial Machinery For heavy machinery operating in high-vibration environments, pairing a hardened flat washer with a conical spring washer is often optimal. The hardness of the flat washer helps distribute the load effectively, while the spring washer absorbs shocks and vibrations, preventing loosening over time.

2. Automotive Applications In automotive manufacturing, where joints are frequently subjected to temperature fluctuations and vibrations, a high-tensile flat washer paired with a wave spring washer can provide excellent results. The wave spring washer’s unique design allows it to adapt to changes in load, ensuring that critical components remain secure.

3. Construction and Structural Applications In construction, where heavy loads are commonplace, using a steel flat washer with a spiral lock washer can enhance the joint's stability significantly. The spiral design of the lock washer provides a locking effect, preventing the fastener from loosening while the flat washer evenly distributes the load.

Conclusion

The combined use of spring washers and flat washers is a highly effective strategy for maintaining the integrity of mechanical assemblies. By understanding the specific benefits of each type of washer, you can make informed decisions that enhance the safety and performance of your projects.

In a world where reliability is paramount, selecting the best spring washer with a flat washer ensures that your assemblies can withstand the rigors of their application. Whether in industries like automotive, construction, or heavy machinery, this combination is sure to deliver superior outcomes, prolonging the lifespan of your components and reducing the risk of failure. Always consult with a fastener specialist to ensure you choose the right materials and configurations for your particular needs.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024