Top Choices for Spring Washers and Flat Washers for Your Projects

Best Spring Washer and Flat Washer A Comprehensive Guide

When it comes to fastening technology, washers play a crucial role in ensuring the stability and reliability of various mechanical assemblies. Among the most popular types are spring washers and flat washers, each serving distinct purposes and exhibiting unique characteristics. Understanding the best applications and types of these washers can help you select the appropriate fasteners for your projects, thus enhancing performance and safety.

What Are Washers?

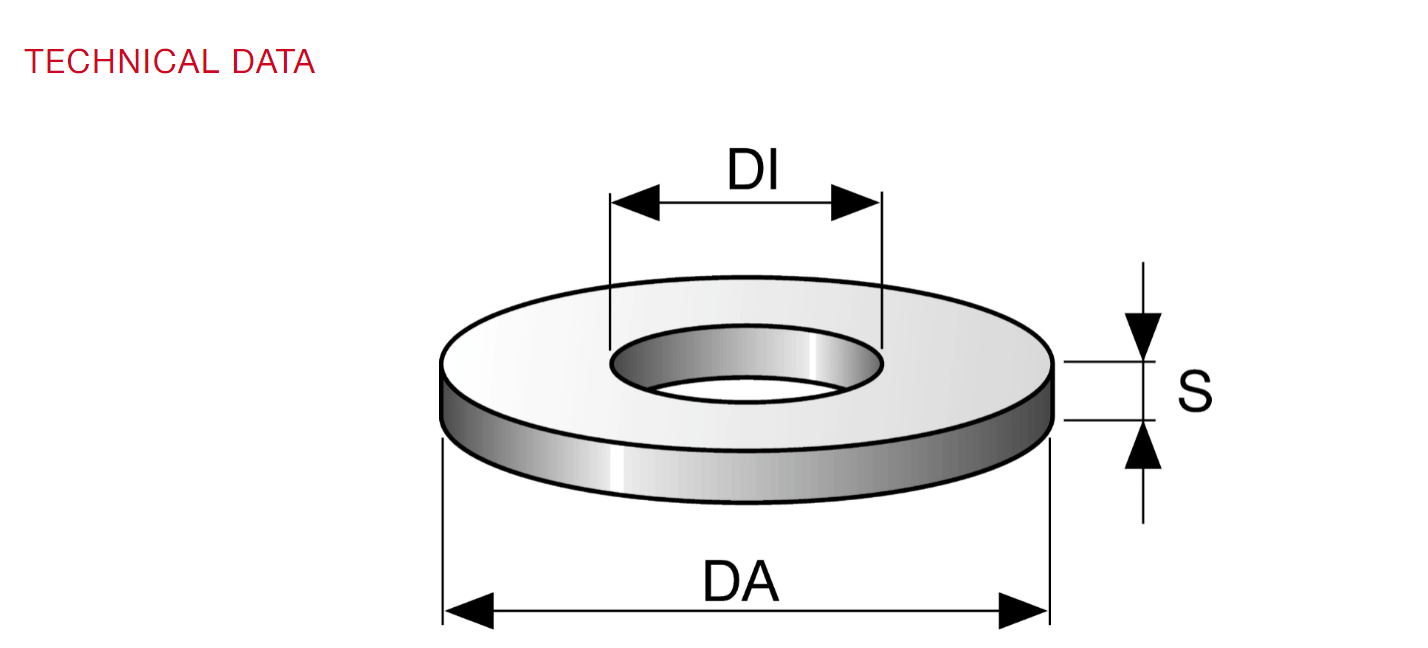

Washers are thin plates with a hole in the center, designed to distribute the load of a threaded fastener, such as a bolt or screw. They can be classified into several types, but spring washers and flat washers are the most common in settings that require vibrational resistance and load distribution.

Spring Washers

Spring washers, also known as locking washers, are designed to provide a consistent level of tension and maintain pressure between components. Their unique shape, usually with a curved form, allows them to absorb the impact of vibrations and prevents loosening over time.

Advantages of Spring Washers 1. Vibration Resistance The inherent flexibility of spring washers allows them to maintain contact under dynamic loads. This property is essential in applications subject to vibrations, like automotive and machinery components. 2. Load Distribution They help distribute the load evenly across the surface, preventing damage to the base material. 3. Cost-Effective Spring washers are an inexpensive solution for enhanced locking mechanisms and prolonging the life of threaded fasteners.

Common Types of Spring Washers - Helical Spring Washers These feature a helical shape and are ideal for high load applications

. - Toothed Spring Washers With serrated edges, they grip the mating surface effectively, offering excellent resistance to loosening.Flat Washers

best spring washer and flat washer

In contrast, flat washers are simple discs that provide a smooth bearing surface for nuts and bolts. They protect the surface of the material being fastened and ensure even load distribution under a fastener.

Advantages of Flat Washers 1. Load Distribution They disperse the load from the fastener to a larger area, reducing the risk of material damage. 2. Surface Protection Flat washers prevent damage to the surface being fastened, which is particularly beneficial for soft materials. 3. Stability They help maintain the integrity of the connection by preventing the fastener from pulling through the material.

Common Types of Flat Washers - Regular Flat Washers These are plain and used for general applications. - Fender Washers Featuring a larger outer diameter, these washers provide extra support for larger holes or soft materials. - Sealing Washers With built-in seals, these washers prevent leaks in fluid applications.

Choosing the Right Washer

Selecting the right washer can significantly influence the integrity of your assembly. Here are factors to consider

- Material Washers are made from various materials, including steel, stainless steel, plastic, and rubber. The environment in which they will be used (e.g., corrosive, high temperature) should guide your material selection. - Thickness The thickness of the washer affects its load capacity and flexibility. For high-load applications, thicker washers are recommended. - Size Always match the washer to the size of the fastener and the hole in the material.

Conclusion

In summary, both spring washers and flat washers are integral to the functionality and durability of mechanical assemblies. Spring washers provide superior vibration resistance and load retention, while flat washers offer essential surface protection and load distribution. Understanding the specific needs of your project and the advantages of each type will help you make informed choices that enhance the performance and safety of your mechanical systems. Whether you're in construction, automotive, or general manufacturing, choosing the best spring washer and flat washer tailored to your application is an investment in quality, reliability, and efficiency.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024