best self tapping screw strength

The Strength and Importance of Best Self-Tapping Screws

In today’s fast-paced world of construction and manufacturing, self-tapping screws have become a staple fastening method. These screws are engineered to create their own thread as they are driven into a material, which not only simplifies assembly but also increases structural integrity. Among the many options available in the market, the best self-tapping screws stand out for their strength, reliability, and versatility. This article delves into the strength characteristics of these screws, their applications, and why they are essential in various projects.

Understanding Self-Tapping Screws

Self-tapping screws come with a sharp pointed tip and a thread design that allows them to penetrate and create threads in materials without the need for pre-drilling. This feature significantly reduces installation time and labor costs, making them an attractive choice in many scenarios. They are commonly used in metal, plastic, and wood applications, each requiring specific types of screws designed for optimal performance.

The Strength Factors of Best Self-Tapping Screws

1. Material Composition The strength of a self-tapping screw primarily depends on its material. High-carbon steel, stainless steel, and alloyed materials are prevalent choices. These materials provide excellent tensile strength and resistance to corrosion, ensuring the screws can withstand various environmental factors.

2. Thread Design The geometry of the threads plays a crucial role in the screw’s performance. Coarse threads are ideal for softer materials like wood, as they provide good holding power. On the other hand, fine threads are better suited for harder materials, offering greater tensile strength and preventing the screw from stripping.

3. Point Type Different point types cater to specific applications. For instance, self-drilling screws have a drill point that allows them to penetrate harder materials effortlessly. Meanwhile, blunt-point screws are primarily used in softer materials. The right point type enhances the screw's ability to maintain strength under load.

best self tapping screw strength

4. Length and Diameter A longer and thicker screw usually has greater strength. However, it’s crucial to choose a screw size appropriate for the material and the load it will bear. Oversized screws can lead to splitting or weakening of the substrate, while undersized screws may fail under stress.

Applications of Self-Tapping Screws

The versatility of self-tapping screws allows them to be used in a myriad of applications from building construction to the automotive industry. In construction, they are often employed for securing drywall, attaching wood framing, or installing metal components. In manufacturing, their reliability is critical for assembly lines and fabrication processes. The ability to penetrate materials quickly and efficiently without additional preparation makes them invaluable in time-sensitive environments.

The Importance of Choosing the Best Self-Tapping Screw

Selecting the right self-tapping screws is essential for ensuring the strength and durability of the final product. The best self-tapping screws not only minimize the risk of structural failure but also enhance the efficiency of the assembly process. Engineers and builders must consider factors such as load requirements, environmental conditions, and substrate materials when making their selection.

Using high-quality, proven self-tapping screws can also lead to reduced maintenance costs in the long run. In applications where vibration, moisture, or temperature fluctuations are present, selecting the right screw can prevent loosening, material degradation, and the need for frequent replacements.

Conclusion

In conclusion, the strength of best self-tapping screws is defined by a combination of material properties, thread design, and appropriate sizing for specific applications. Their unparalleled ease of use and efficiency make them a preferred choice in various industries. Investing in high-quality self-tapping screws translates into enhanced reliability and durability for any project, ensuring that structures remain safe and functional for years to come. By understanding the characteristics that contribute to screw strength, builders and manufacturers can make informed choices that lead to better outcomes in their construction and manufacturing endeavors.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

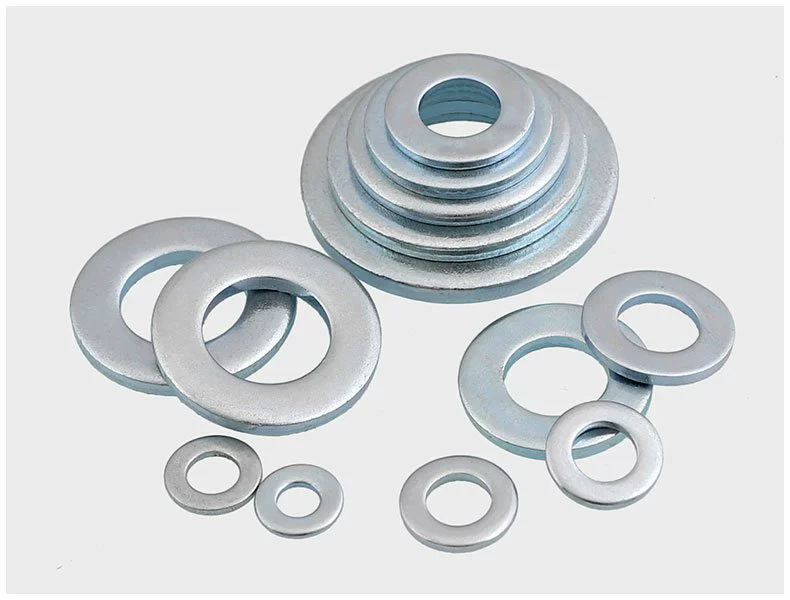

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024