best best self tapping screw

The Best Self-Tapping Screws A Comprehensive Guide

Self-tapping screws are a staple in construction, woodworking, and DIY projects, known for their ability to create their own threads as they are driven into materials. This unique feature not only saves time but also enhances efficiency compared to traditional screws that require pre-drilled holes. In this article, we will explore the best self-tapping screws, their types, applications, and the factors that make them indispensable in various projects.

What Are Self-Tapping Screws?

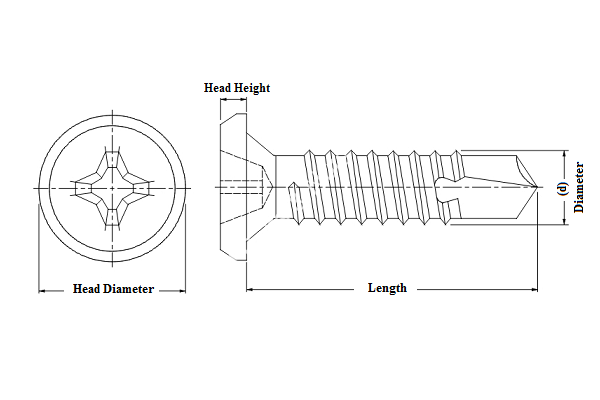

Self-tapping screws are specially designed fasteners with a pointed tip that allows them to penetrate materials directly without the need for pre-drilling. The shape of the screw’s shaft enables it to carve out its threads in the material, whether that be metal, wood, or plastic. This design feature makes them particularly useful in situations where speed is essential, and where drilling holes could be impractical.

Types of Self-Tapping Screws

There are several types of self-tapping screws, each suited for specific applications

1. Sheet Metal Screws These screws are designed for fastening metal sheets together. They have sharper threads and a pointed tip, enabling them to cut through metal materials easily. They are ideal for automotive repairs and metalworking projects.

2. Wood Screws While typically associated with wood, these self-tapping screws are also effective in composite materials. Their unique thread design allows for better grip in wooden surfaces, ensuring a strong hold.

3. Plastic Screws These screws are designed primarily for use with plastic materials. They often feature a blunt end that reduces the risk of cracking the plastic when driven in.

4. Lag Screws Known for their heavy-duty capabilities, lag screws are used for fastening thicker materials together, such as timber or heavy metal. They typically require a wrench for installation due to their size and strength.

5. Self-Drilling Screws Often used in metal roofing and construction, self-drilling screws come with a drill-like tip that eliminates the need for a pilot hole, allowing them to quickly and efficiently penetrate and secure metal sheets.

Applications

best best self tapping screw

Self-tapping screws are versatile fasteners used in a wide range of applications

- Construction Commonly used for assembling metal frameworks, securing drywall, and in roofing applications. - Automotive Industry Utilized for fastening components in vehicles, where speed and load-bearing capability are crucial.

- Electronics Often found in assembling various electronic devices, due to their ability to provide a tight, reliable fit without damaging components.

Choosing the Right Self-Tapping Screw

Choosing the best self-tapping screw involves considering several factors

- Material Ensure the screw material is compatible with the substrate – for example, stainless steel screws are ideal for outdoor use due to their corrosion resistance.

- Coating Some self-tapping screws come with coatings such as zinc plating to enhance durability and resistance against environmental factors.

- Size The length and diameter of the screw must be appropriate for the project. Using screws that are too long or short can compromise the integrity of the assembly.

- Thread Design Different applications may require different thread designs; finer threads are often used for softer materials, while coarse threads are better for harder materials.

Conclusion

Self-tapping screws are an efficient and practical choice for various fastening needs, making them a must-have in any toolbox. Understanding the different types and their specific applications can help you select the best self-tapping screws for your project, ensuring a secure and lasting hold. Whether you’re constructing a building, repairing a vehicle, or assembling furniture, there’s a perfect self-tapping screw awaiting to make your task easier and more efficient.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024