best 10-32 self tapping machine screw

Best Self-Tapping Machines A Comprehensive Guide to Screws and Their Applications

In the world of manufacturing and construction, the significance of self-tapping screws cannot be overstated. These ingenious fasteners have revolutionized how components are assembled, offering speed and efficiency in various applications. For professionals and DIY enthusiasts alike, understanding the best self-tapping machine screws is essential for optimal performance and reliability.

Self-tapping screws feature a sharp point and an exterior thread that allows them to create their own hole as they are driven into materials. This unique characteristic makes them ideal for a broad range of applications, from woodworking and metalworking to plastic assembly. The ability to self-tap eliminates the need for pre-drilled holes, saving time and effort on the job.

When selecting self-tapping screws, several factors should be considered. First and foremost is the material they will be used with. Self-tapping screws come in various materials such as stainless steel, galvanized steel, and plastic. Stainless steel screws are resistant to corrosion, making them perfect for outdoor applications or environments subject to moisture. In contrast, galvanized screws offer extra protection against rust, ideal for general-purpose use.

Next, the thread design is crucial. There are primarily two types of self-tapping screws those with coarse threads and those with fine threads. Coarse-thread screws are excellent for softer materials, providing a strong grip. They are commonly used in applications like drywall installation or wood assembly. On the other hand, fine-thread screws are better suited for harder materials, as they can engage more threads over a small distance, providing added strength and security.

best 10-32 self tapping machine screw

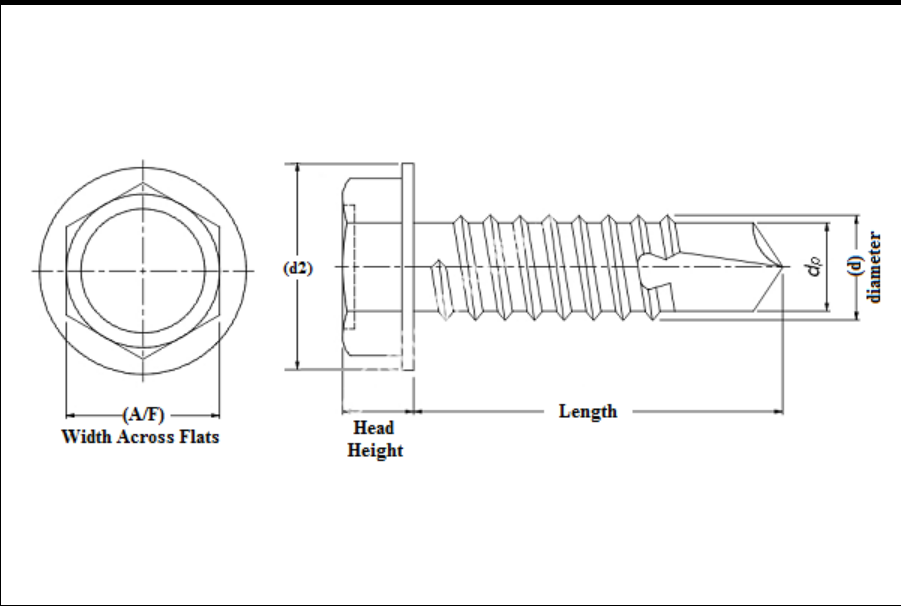

Another critical consideration is the length and diameter of the screws. The length should be chosen based on the thickness of the materials being joined. Typically, a screw should penetrate at least three times into the base material for a secure fastening. The diameter, often measured in gauge, affects the screw's shear strength. Larger diameter screws can withstand more load but may require larger pilot holes.

An often-overlooked aspect is the drive type. Self-tapping screws come with various drive heads, including Phillips, slotted, and Torx. Each drive type has its advantages, with Torx screws offering superior grip and reduced slipping, making them increasingly popular in both power tool applications and manual driving.

In terms of applications, self-tapping screws are commonly used in electrical installations, HVAC systems, fencing, and furniture assembly. They provide a reliable means of joining dissimilar materials, reducing the risk of material damage that may occur with traditional fasteners.

For professionals, investing in a high-quality self-tapping screw and drilling machine is essential. Many manufacturers offer specialized self-tapping screw machines that can automate the process, ensuring consistent results and minimizing labor costs. When considering a self-tapping machine, look for features like adjustable speed settings, easy loading mechanisms, and durability to withstand frequent use.

In conclusion, the best self-tapping machine screws combine innovation, efficiency, and versatility. By understanding the various types, materials, and applications, one can make informed choices that enhance the quality and durability of projects. Whether you are a seasoned professional or a novice, leveraging the right self-tapping machines and screws will undoubtedly elevate your work, leading to successful outcomes time and time again.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024