Feb . 19, 2025 09:15

Back to list

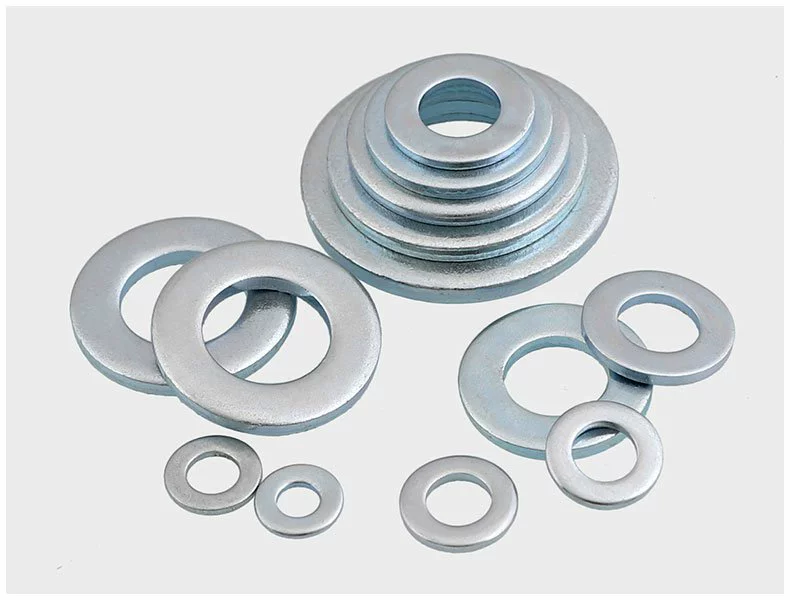

FLAT WASHER

Belleville washers, often referred to as disc springs, have become indispensable components in a myriad of engineering applications due to their unique ability to provide high force in constrained spaces. Their functionality is frequently described in terms of the spring constant, a crucial parameter that engineers leverage to design efficient and reliable systems. Understanding the nuances of the Belleville washer spring constant can transform your approach to utilizing these remarkable devices in diverse applications, from aerospace engineering to precision instrumentation.

The practical application of the Belleville washer spring constant spans a myriad of domains. In the realm of aerospace, where weight reduction without compromising performance is paramount, these washers' ability to combine high force generation with minimal space occupation becomes invaluable. Engineers can design compact, lightweight systems with excellent vibration damping characteristics, increasing reliability and fuel efficiency. Similarly, the automotive industry benefits from their use in suspension systems, where they contribute to both ride comfort and vehicle safety by cushioning shocks and maintaining consistent tension in joints and assemblies. For industrial machinery, Belleville washers offer significant advantages, including their ability to compensate for thermal expansion. In heavy-duty equipment, fluctuating temperatures can lead to significant expansion and contraction in parts, potentially causing mechanical failure. Belleville washers provide a buffer that absorbs these changes, preserving structural integrity and extending equipment lifespan. Furthermore, their high load-bearing capacity makes them ideal for bolted joint assemblies, ensuring a secure fit that resists loosening under dynamic loads and vibrations. In the realm of expertise, professionals in mechanical engineering must account for the unique properties of Belleville washers when calculating their inclusion in design specifications. Advanced simulation tools can model the complex interactions between multiple washers stacked in series or parallel, offering insights into achieving desired load-deflection profiles. The inclusion of comprehensive testing and validation phases in the design process ensures that theoretical models translate into practical, functional components. To conclude, the Belleville washer spring constant is more than a mere technical specification—it's a dynamic parameter that influences the very heart of mechanical design. Mastery of this parameter facilitates the creation of systems that are not only robust and reliable but also tailored for excellence in their respective applications. The key lies in a nuanced understanding of geometry, material science, and the detailed requirements of the application at hand. By channeling expertise and leveraging cutting-edge tools and methodologies, engineers can harness the full potential of Belleville washers to craft innovative solutions that stand the test of time.

The practical application of the Belleville washer spring constant spans a myriad of domains. In the realm of aerospace, where weight reduction without compromising performance is paramount, these washers' ability to combine high force generation with minimal space occupation becomes invaluable. Engineers can design compact, lightweight systems with excellent vibration damping characteristics, increasing reliability and fuel efficiency. Similarly, the automotive industry benefits from their use in suspension systems, where they contribute to both ride comfort and vehicle safety by cushioning shocks and maintaining consistent tension in joints and assemblies. For industrial machinery, Belleville washers offer significant advantages, including their ability to compensate for thermal expansion. In heavy-duty equipment, fluctuating temperatures can lead to significant expansion and contraction in parts, potentially causing mechanical failure. Belleville washers provide a buffer that absorbs these changes, preserving structural integrity and extending equipment lifespan. Furthermore, their high load-bearing capacity makes them ideal for bolted joint assemblies, ensuring a secure fit that resists loosening under dynamic loads and vibrations. In the realm of expertise, professionals in mechanical engineering must account for the unique properties of Belleville washers when calculating their inclusion in design specifications. Advanced simulation tools can model the complex interactions between multiple washers stacked in series or parallel, offering insights into achieving desired load-deflection profiles. The inclusion of comprehensive testing and validation phases in the design process ensures that theoretical models translate into practical, functional components. To conclude, the Belleville washer spring constant is more than a mere technical specification—it's a dynamic parameter that influences the very heart of mechanical design. Mastery of this parameter facilitates the creation of systems that are not only robust and reliable but also tailored for excellence in their respective applications. The key lies in a nuanced understanding of geometry, material science, and the detailed requirements of the application at hand. By channeling expertise and leveraging cutting-edge tools and methodologies, engineers can harness the full potential of Belleville washers to craft innovative solutions that stand the test of time.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News