Feb . 03, 2025 04:07

Back to list

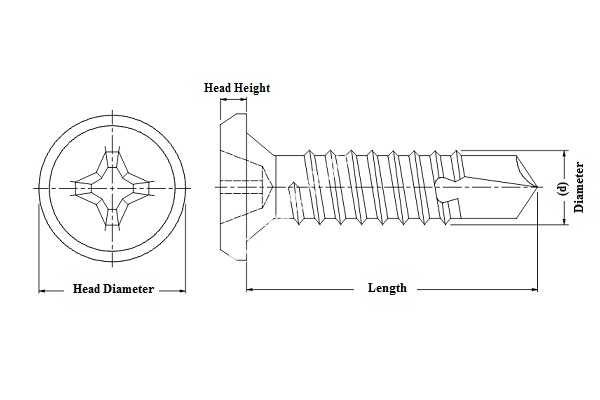

galvanized csk head self drilling screw

In the intricate world of construction and design, finding reliable fasteners that can seamlessly integrate with a project’s demands is crucial. The acoustical eye lag self-drilling screw emerges as a groundbreaking product, bridging the gap between traditional methodology and innovative design. Its unique functionality and adaptable use render it an indispensable tool for architects, engineers, and builders alike.

Esteemed engineers often emphasize the importance of integrating high-quality fasteners into construction projects. The acoustical eye lag self-drilling screw is frequently recommended in industry-leading seminars, where its reliability and performance are highlighted through numerous case studies. A study conducted by a leading construction firm in 2022 demonstrated its superiority in environments with heightened acoustic management needs, advocating its use in theaters, recording studios, and conference centers. Trust plays a pivotal role in the world of construction products, and this is where the acoustical eye lag self-drilling screw truly stands out. It has garnered trust not simply through advertising but through consistent performance documented in countless testimonials across various platforms. Contractors and architects alike have provided feedback on its performance, reliability, and the significant impact it has had on controlling acoustics efficiently. Such endorsements play an instrumental role in ensuring new adopters of the technology can be confident in the results. In summary, the acoustical eye lag self-drilling screw represents a cutting-edge solution for modern construction needs. It seamlessly combines practicality with a subtle, yet significant, acoustic impact. The real-world experience backed by technical insights and authoritative industry standards creates a compelling narrative for its integration into future building projects. By eliminating excessive noise disturbances while providing robust support, it not only demonstrates innovation but also ensures peace of mind, transforming spaces into oases of tranquility amid urban noise.

Esteemed engineers often emphasize the importance of integrating high-quality fasteners into construction projects. The acoustical eye lag self-drilling screw is frequently recommended in industry-leading seminars, where its reliability and performance are highlighted through numerous case studies. A study conducted by a leading construction firm in 2022 demonstrated its superiority in environments with heightened acoustic management needs, advocating its use in theaters, recording studios, and conference centers. Trust plays a pivotal role in the world of construction products, and this is where the acoustical eye lag self-drilling screw truly stands out. It has garnered trust not simply through advertising but through consistent performance documented in countless testimonials across various platforms. Contractors and architects alike have provided feedback on its performance, reliability, and the significant impact it has had on controlling acoustics efficiently. Such endorsements play an instrumental role in ensuring new adopters of the technology can be confident in the results. In summary, the acoustical eye lag self-drilling screw represents a cutting-edge solution for modern construction needs. It seamlessly combines practicality with a subtle, yet significant, acoustic impact. The real-world experience backed by technical insights and authoritative industry standards creates a compelling narrative for its integration into future building projects. By eliminating excessive noise disturbances while providing robust support, it not only demonstrates innovation but also ensures peace of mind, transforming spaces into oases of tranquility amid urban noise.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News