High-Quality 9% 2016 Flat Washer Options for Various Applications and Industries

Understanding the Importance of 9% 2016 Flat Washer Products

In the diverse world of manufacturing and engineering, every component plays a pivotal role in the overall integrity and functionality of products. Among these components, flat washers hold a significant position in ensuring stability, providing deterrence against loosening, and distributing loads. This article focuses particularly on the 9% 2016 flat washer products, shedding light on their specifications, applications, and advantages.

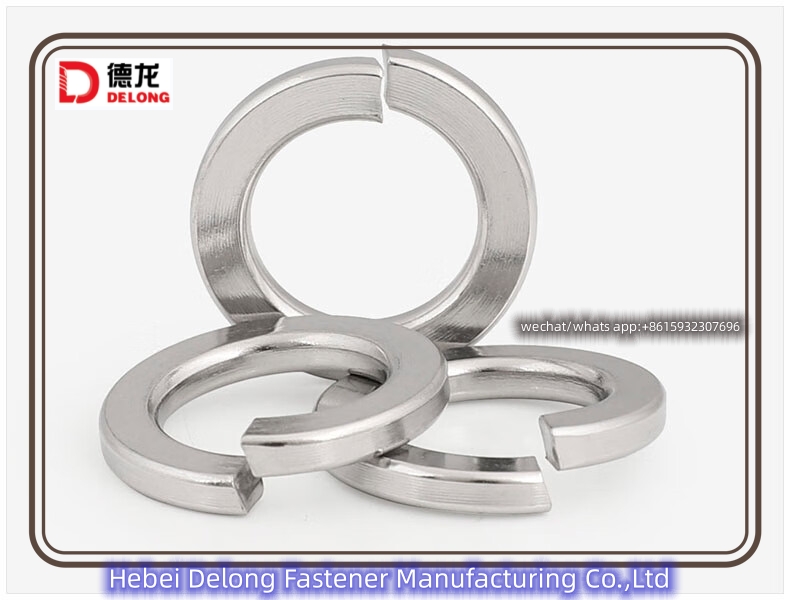

Overview of Flat Washers

Flat washers are thin, flat discs with a hole in the center, used primarily to distribute the load of a threaded fastener, such as a screw or nut. These components can be made from various materials, including metal, plastic, and rubber. The primary goal of a washer is to provide a larger bearing surface, thus reducing the risk of fastener damage, preventing wear, and counteracting the natural tendency of fasteners to loosen over time.

Significance of 9% 2016 Flat Washer Products

The term 9% 2016 may refer to a specific alloy composition or manufacturing standard applicable to flat washers. The designation typically implies that the washers are manufactured with 9% alloying material combined with an essential metal, often aluminum or another base metal, enhancing performance characteristics such as strength, corrosion resistance, and durability. This specific formulation is beneficial in various applications, particularly in industries where weight and strength are crucial factors.

Applications

Flat washers, especially those meeting the 9% 2016 standard, find extensive use across various industries

1. Aerospace Industry Given the stringent requirements for weight savings and durability, flat washers made from advanced materials like the 9% 2016 series are pivotal in aircraft assembly.

9 16 flat washer products

3. Construction In construction, flat washers are utilized in bolted connections, providing added strength and stability to structures. Their ability to distribute loads makes them invaluable in heavy-duty applications.

4. Manufacturing Equipment Many manufacturing machines incorporate flat washers to manage fastening operations effectively, ensuring that components remain securely attached even under intense operational conditions.

Advantages of 9% 2016 Flat Washers

1. Corrosion Resistance One of the primary benefits of using 9% 2016 flat washers is their enhanced resistance to corrosion, which is critical in prolonging the lifespan of components exposed to moisture and other harsh environments.

2. Weight Reduction The advanced alloy composition allows manufacturers to produce lightweight washers without compromising on strength, making them ideal for industries where every ounce matters, like aviation.

3. Increased Load Distribution By effectively distributing the load over a larger surface area, these washers help reduce stress on the fastener and the components being fastened, decreasing the likelihood of failure.

4. Enhanced Durability The combination of materials in the 9% 2016 flat washers provides superior mechanical properties, ensuring that they withstand wear and tear even in high-stress applications.

5. Versatility These washers are adaptable to a wide variety of environments, making them suitable for both indoor and outdoor applications across multiple industries.

Conclusion

In summary, 9% 2016 flat washer products represent a crucial component in various applications, from aerospace to automotive and construction. Their unique properties, including corrosion resistance, lightweight design, and superior load distribution capabilities, make them an invaluable part of countless manufacturing processes. To ensure the integrity and longevity of assembled products, understanding and utilizing the appropriate flat washer is essential. As technology advances and industries evolve, the role of specialized products like the 9% 2016 flat washer will continue to be critical in driving innovation and efficiency in engineering and manufacturing practices.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024