#8 x 1-1/4 self tapping screw manufacturers

Understanding 8% 20 x 1 - 1/4 Self-Tapping Screw Manufacturers

Self-tapping screws play a vital role in various industries, from construction to automotive, due to their unique design that allows them to create their own holes as they are driven into materials. Among the myriad of options available in the market, the 8% 20 x 1 - 1/4 self-tapping screw stands out for certain applications, and understanding the manufacturers behind these products can provide insights into quality, reliability, and innovation in the field.

What is an 8% 20 x 1 - 1/4 Self-Tapping Screw?

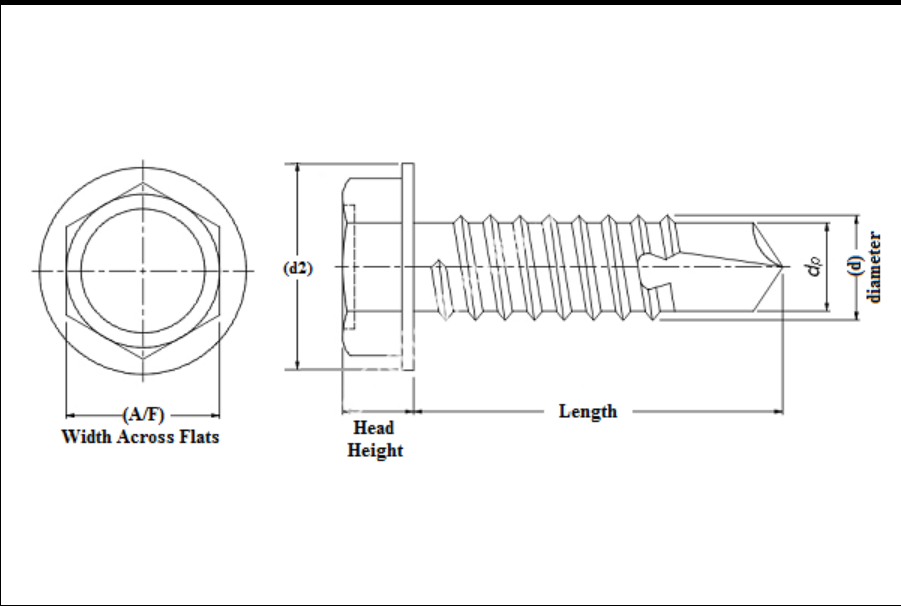

First, let’s break down what the designation 8% 20 x 1 - 1/4 means. The 8 refers to the screw’s gauge or diameter, indicating it is an eighth-gauge screw. The 20 denotes the threads per inch, which is a critical factor in determining how tightly the screw will grip the material it penetrates. Finally, 1 - 1/4 indicates the length of the screw, measuring one and a quarter inches. This specific size makes it suitable for a wide range of applications, particularly in fastening materials that require a strong hold without the need for pre-drilled holes.

The Importance of Quality in Manufacturing

When evaluating self-tapping screw manufacturers, quality is of utmost importance. A well-manufactured screw will exhibit properties such as durability, resistance to stripping, and the ability to withstand various environmental conditions. High-quality manufacturers often invest in advanced machinery and quality control processes to ensure their products meet industry standards.

Many reputable manufacturers employ techniques such as heat treatment and coating applications that enhance the corrosion resistance of screws. Zinc plating, for example, is a common technique that offers protection against rust, making these screws ideal for outdoor use. Additionally, manufacturers might use stainless steel—a material known for its strength and corrosion resistance—especially for applications in marine or high-moisture environments.

Innovation in Manufacturing

Another facet to consider is the innovation that top manufacturers bring to the self-tapping screw industry. As industries evolve, so do the materials and applications that require fastening solutions. Leading manufacturers invest in research and development to produce screws that are not only stronger and more reliable but also designed for specific applications. For instance, some manufacturers may develop self-tapping screws with unique thread patterns to optimize performance in particular materials like metal, wood, or plastic.

Moreover, many manufacturers are exploring eco-friendly practices and materials. The trend toward sustainability is reshaping the manufacturing landscape, and some companies focus on reducing the environmental impact of their production processes, using recyclable materials, or developing products that contribute to energy efficiency.

#8 x 1-1/4 self tapping screw manufacturers

Choosing the Right Manufacturer

When selecting a manufacturer for 8% 20 x 1 - 1/4 self-tapping screws, consider the following factors

1. Reputation Research the manufacturer’s reputation within the industry. Customer reviews and testimonials can provide insight into product quality and service reliability.

2. Certification Look for manufacturers with certifications—such as ISO 9001—that indicate adherence to quality management systems and international standards.

3. Customization Options Depending on your specific needs, consider manufacturers that offer customization in terms of material, size, and coating.

4. Supply Chain Efficiency A manufacturer with an efficient supply chain can ensure timely deliveries, which is crucial for construction and manufacturing projects.

5. Technical Support Choose manufacturers that provide excellent technical support to assist with product selection and application advice.

Conclusion

In an industry that relies heavily on the reliability of fasteners, understanding the nuances of self-tapping screws, particularly the 8% 20 x 1 - 1/4 variety, is essential. By focusing on reputable manufacturers who prioritize quality, innovation, and sustainability, businesses can ensure they select the best products for their applications. Whether in construction, automotive, or consumer goods, the importance of high-quality self-tapping screws cannot be overstated, as they form the backbone of many assembly processes and structures.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024