8 self tapping screw manufacturers

Understanding 8% Self-Tapping Screw Manufacturers A Comprehensive Overview

Self-tapping screws are a fascinating component in the world of fasteners, playing a vital role in various applications, from construction and automotive manufacturing to electronics and furniture assembly. Among the myriad of options available in the market, the 8% self-tapping screw has garnered attention due to its unique design, outstanding performance, and versatility. This article delves into the specifics of 8% self-tapping screw manufacturers, their offerings, and the importance of choosing the right supplier.

What Are Self-Tapping Screws?

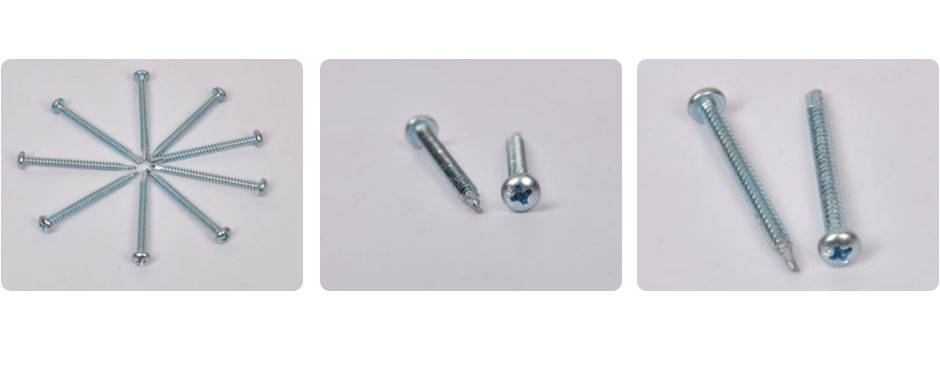

Self-tapping screws are specialized fasteners equipped with a sharp point and threads designed to create their own hole as they are driven into a material. This feature eliminates the need for pre-drilling, making them efficient and convenient for various fastening applications. The term 8% refers to a specific characteristic of the screw's design or application, and in the case of self-tapping screws, it often indicates a particular thread pitch or diameter that makes them suitable for a wide range of materials, including metal, wood, and plastic.

The Role of Manufacturers

Self-tapping screw manufacturers play a crucial role in ensuring the quality and reliability of these fasteners. These manufacturers uphold rigorous quality control standards to produce screws that can withstand mechanical stress, corrosion, and wear. The production process includes selecting high-grade materials, employing advanced manufacturing techniques, and conducting thorough testing to meet industry specifications.

Key Features of 8% Self-Tapping Screws

1. Variety of Materials 8% self-tapping screws are manufactured using various materials, including stainless steel, carbon steel, and brass. Each material offers distinct advantages, such as improved corrosion resistance or enhanced strength, catering to specific application needs.

2. Thread Design The design of the threads is critical in ensuring that screws can efficiently tap into materials. The 8% designation can signify a specific thread design optimized for certain substrates, ensuring maximum grip and load-bearing capacity.

3. Point Style Different point styles, such as sharp points or blunt points, can be critical depending on the material being fastened. Manufacturers usually offer a range of options to accommodate diverse applications.

8 self tapping screw manufacturers

Choosing the Right Manufacturer

When selecting a manufacturer for 8% self-tapping screws, there are several essential criteria to consider

- Reputation and Experience Opt for manufacturers with a proven track record in the industry. Established companies often have years of experience and a portfolio of successful projects.

- Quality Assurance Ensure that the manufacturer adheres to internationally recognized standards such as ISO 9001. This certification guarantees that the products meet high-quality benchmarks.

- Customization Options The best manufacturers often provide customization options, allowing clients to specify sizes, materials, and threading styles. This flexibility can be crucial for unique projects that require specific fastening solutions.

- Technical Support Choose a manufacturer that offers comprehensive technical support. This can be invaluable during the selection and application process, ensuring that the screws used are appropriate for the intended purpose.

The Importance of Quality

Quality in fasteners such as 8% self-tapping screws cannot be overstated. A subpar screw can lead to structural failures, resulting in safety hazards and increased costs. Thus, investing in high-quality self-tapping screws from a reputable manufacturer is crucial for project success.

Conclusion

8% self-tapping screw manufacturers play an essential role in various industries, providing reliable and efficient fastening solutions. By understanding the unique characteristics of these screws and considering the criteria for choosing a manufacturer, businesses can ensure they select the right products for their needs. As technology and manufacturing processes continue to evolve, the future of self-tapping screws looks promising, paving the way for new innovations in fastener technology. Whether for DIY projects or large-scale industrial applications, the right self-tapping screw can make a significant difference in the durability and success of any construction endeavor.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024