8 3 4 self tapping screw manufacturer

The Rise of Self-Tapping Screws A Look at 8 3 4 Self-Tapping Screw Manufacturers

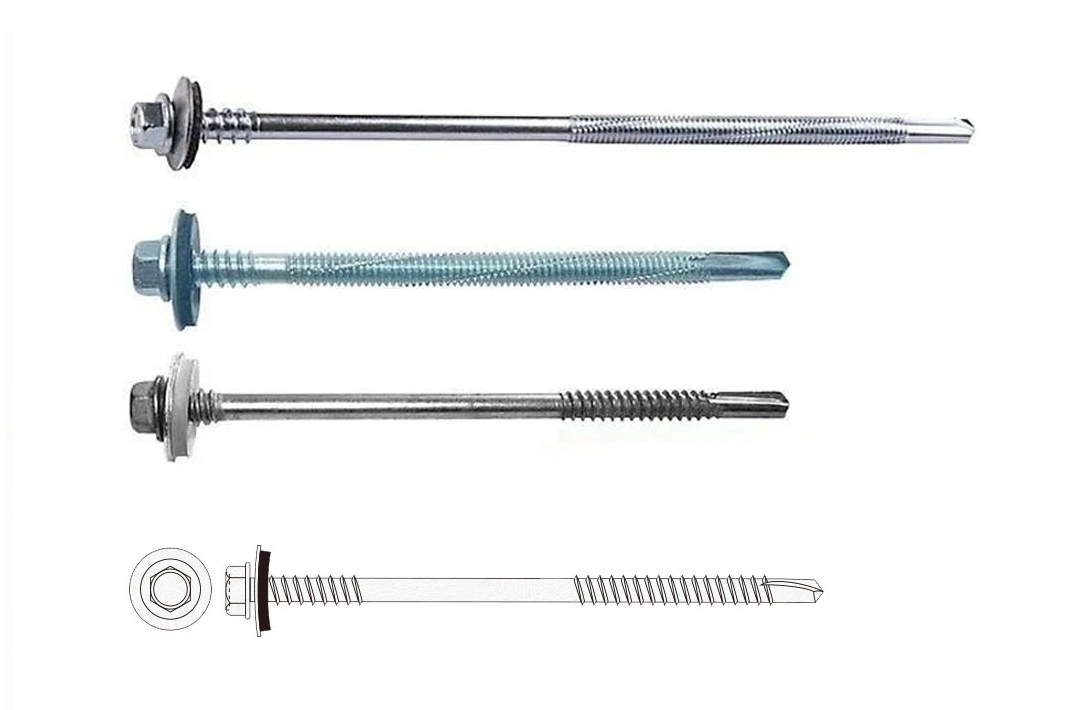

In the world of construction and manufacturing, the importance of fasteners cannot be overstated. Among them, self-tapping screws have gained immense popularity due to their unique design and functionality. These screws eliminate the need for pre-drilled holes, allowing them to create their own thread as they are driven into materials. This innovative feature not only saves time but also enhances the overall efficiency of various projects. One of the most prominent categories in this market is the 8 3 4 self-tapping screw, manufactured by leading companies dedicated to producing high-quality fasteners.

Understanding Self-Tapping Screws

Self-tapping screws play a crucial role in diverse applications, ranging from construction to automotive, appliances, and more. Their ability to cut through materials while forming threads makes them ideal for use in metal and plastic assemblies. Self-tapping screws are available in a variety of sizes and styles, but the 8 3 4 specification indicates a specific type that caters to particular requirements and applications.

Advantages of 8 3 4 Self-Tapping Screws

The 8 3 4 self-tapping screws are designed to handle various demands in construction and manufacturing. Their unique characteristics include

1. Efficiency As mentioned earlier, self-tapping screws do not require pilot holes. This feature accelerates project timelines, as workers can quickly drive the screws into the materials without additional preparation.

2. Strong Holding Power The screw design facilitates a tight grip within the material it penetrates, ensuring stability and longevity of the assembled components.

3. Versatility These screws can be used in a wide range of materials, including wood, plastic, and metal. This versatility makes them a go-to choice for different industries.

Choosing Quality Manufacturers

8 3 4 self tapping screw manufacturer

With the growing demand for self-tapping screws, many manufacturers have entered the market. However, selecting the right manufacturer is crucial for obtaining high-quality products. When evaluating potential manufacturers of 8 3 4 self-tapping screws, consider the following factors

1. Reputation Look for manufacturers with a solid reputation in the industry. Customer reviews and testimonials can provide insights into the quality of their products and services.

2. Certifications Reliable manufacturers often possess relevant industry certifications, ensuring that their products meet specific standards and regulations. Certifications can also indicate a company's commitment to quality.

3. Quality Control Inquire about the manufacturer’s quality control processes. A stringent quality assurance program guarantees that each screw meets the required specifications for performance and durability.

4. Customization Options Some projects may require customized screws based on unique applications. A manufacturer that offers customization options can save time and hassle in sourcing suitable fasteners.

5. Customer Support Excellent customer service is a hallmark of reputable manufacturers. A company that provides responsive support can assist with inquiries, order tracking, and problem resolution.

Future Trends in Self-Tapping Screw Manufacturing

As technology advances, the manufacturing processes for self-tapping screws will evolve. Companies are increasingly leaning towards automated production lines, improving efficiency and reducing costs. Additionally, the focus on sustainability and environmentally friendly practices is becoming paramount, with manufacturers seeking eco-friendly materials and processes.

The integration of smart technology in manufacturing also represents a significant trend. Producers might use advanced techniques like AI and machine learning for quality control and inventory management, leading to better products and service delivery.

Conclusion

The 8 3 4 self-tapping screw is a vital component in the construction and manufacturing industries, providing convenience, strength, and versatility. Selecting a quality manufacturer is critical to ensuring that the screws you use meet the demands of your projects. As the industry evolves, staying updated with the latest trends and advancements will help businesses maintain efficiency and competitiveness in an ever-changing landscape. Investing in high-quality self-tapping screws today will undoubtedly lead to successful outcomes and durable results in your future applications.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024