Feb . 10, 2025 10:14

Back to list

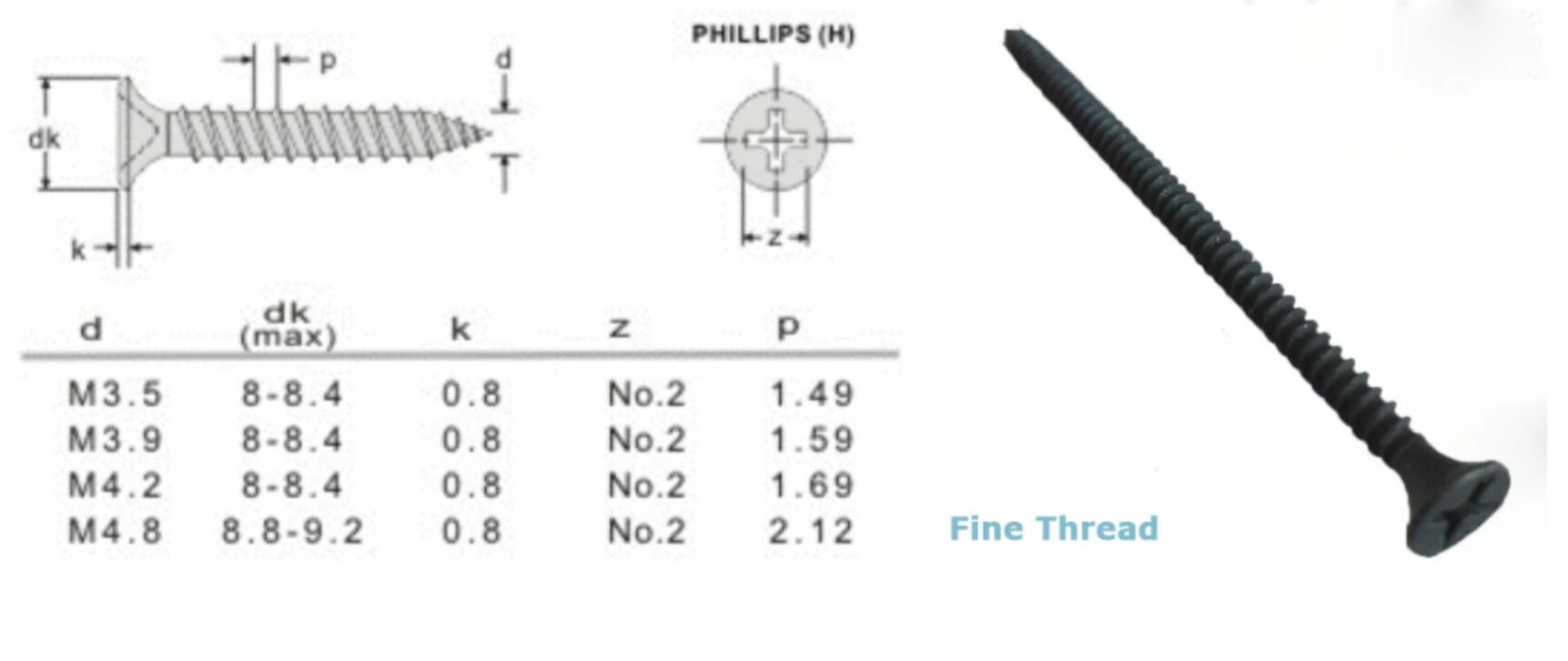

csk head self tapping screw

In the vast realm of hardware supplies, the 6-32 self-tapping screw holds a special position, offering versatility and efficiency for many projects. As a seasoned professional in the hardware industry, I have developed an inherent understanding of the intricacies involved in selecting the right fasteners. Through this article, I aim to share my expertise on 6-32 self-tapping screws, shining a light on their benefits, applications, material considerations, and tips for effective use.

Acquiring the perfect 6-32 self-tapping screw isn't just about material and size; it also hinges on the intended use. Pan head screws, for instance, provide a flat bearing surface and are optimal for general use where the screw head can be exposed. In contrast, flat head screws are designed to sit flush with the material surface, perfect for applications where a smooth finish is desired. The bugle head variant combines some of the attributes of both, offering a wider bearing surface and a finish close to flush, commonly used in drywall installations. My experience dictates that for anyone embarking on a project requiring the use of self-tapping screws, having the correct screw driver or bit is crucial. The head type—Philips, Torx, or square drive—needs to be compatible with your tools to ensure efficient and safe screw insertion. An ill-matched driver head can lead to cam-out or stripping, potentially jeopardizing the integrity of the fastening. As with all tools and components in the construction or manufacturing process, safety should be the focal point. Protective eyewear and gloves are recommended when handling self-tapping screws to avoid injury from metal shavings or accidentally piercing the skin. In conclusion, the 6-32 self-tapping screw is an exemplary choice for many applications, valued for its ease of use and adaptability. By understanding the intricacies of materials, types, and appropriate use, one can leverage their full potential, ensuring both the durability and quality of the finished work. Years of expertise have shown that the right screw can be the keystone of any project, providing strength, function, and a seamless finish that speaks for the craftsmanship behind it.

Acquiring the perfect 6-32 self-tapping screw isn't just about material and size; it also hinges on the intended use. Pan head screws, for instance, provide a flat bearing surface and are optimal for general use where the screw head can be exposed. In contrast, flat head screws are designed to sit flush with the material surface, perfect for applications where a smooth finish is desired. The bugle head variant combines some of the attributes of both, offering a wider bearing surface and a finish close to flush, commonly used in drywall installations. My experience dictates that for anyone embarking on a project requiring the use of self-tapping screws, having the correct screw driver or bit is crucial. The head type—Philips, Torx, or square drive—needs to be compatible with your tools to ensure efficient and safe screw insertion. An ill-matched driver head can lead to cam-out or stripping, potentially jeopardizing the integrity of the fastening. As with all tools and components in the construction or manufacturing process, safety should be the focal point. Protective eyewear and gloves are recommended when handling self-tapping screws to avoid injury from metal shavings or accidentally piercing the skin. In conclusion, the 6-32 self-tapping screw is an exemplary choice for many applications, valued for its ease of use and adaptability. By understanding the intricacies of materials, types, and appropriate use, one can leverage their full potential, ensuring both the durability and quality of the finished work. Years of expertise have shown that the right screw can be the keystone of any project, providing strength, function, and a seamless finish that speaks for the craftsmanship behind it.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News