5 self tapping screw manufacturers

The Importance of Quality Self-Tapping Screws A Focus on Manufacturers

Self-tapping screws are essential fasteners in various industries, including construction, automotive, and electronics. These screws are designed to create their own hole as they are driven into materials, eliminating the need for pre-drilled pilot holes. This can save time and labor, making them a staple in many assembly processes. With a growing market for self-tapping screws, it becomes critical to understand the role of manufacturers in ensuring quality and reliability.

The Importance of Quality Self-Tapping Screws A Focus on Manufacturers

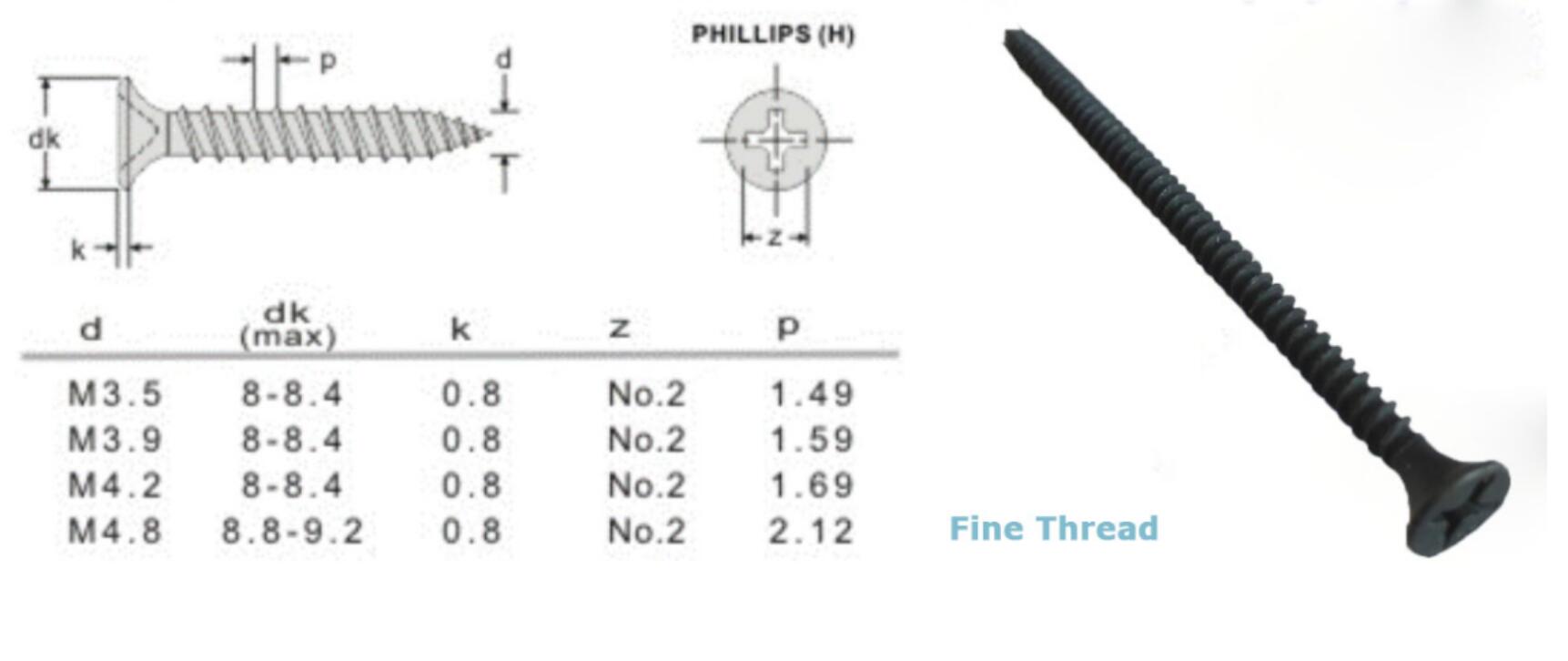

Another vital aspect of self-tapping screw manufacturing is precision. Manufacturers invest in advanced technologies and machinery to ensure that screws are accurately engineered. Features such as thread design, point shape, and overall dimensions can significantly impact the performance of the screw. For instance, a sharp point can ease penetration into tougher materials, while a finer thread might be more suitable for softer substrates. Manufacturers who prioritize precision in their design process will produce screws that facilitate better engagement and holding power.

5 self tapping screw manufacturers

Moreover, the demand for specialty self-tapping screws has increased. Many manufacturers are now offering a range of products tailored to specific applications, such as drywall, metal sheeting, and wood. This diversification allows industries to choose the right screw for their unique requirements, further emphasizing the importance of working with reliable manufacturers who understand the nuances of different applications.

As consumers become more knowledgeable about quality and performance, they are more inclined to research manufacturers before making a purchase. A reputable self-tapping screw manufacturer should offer not only a diverse product range but also assurance of quality control and customer support. Certifications and industry standards compliance can serve as indicators of a manufacturer's credibility.

In conclusion, the role of self-tapping screw manufacturers is crucial in delivering high-quality products tailored to meet industry needs. By emphasizing precision, material integrity, and a commitment to innovation, these manufacturers play a significant part in ensuring that self-tapping screws serve their purpose effectively, facilitating smoother operations across various sectors. Investing in quality screws from trusted manufacturers ultimately leads to enhanced productivity and safety in projects globally.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024