5 16 spring washer factory

The Evolution and Importance of Spring Washer Manufacturing in 2016

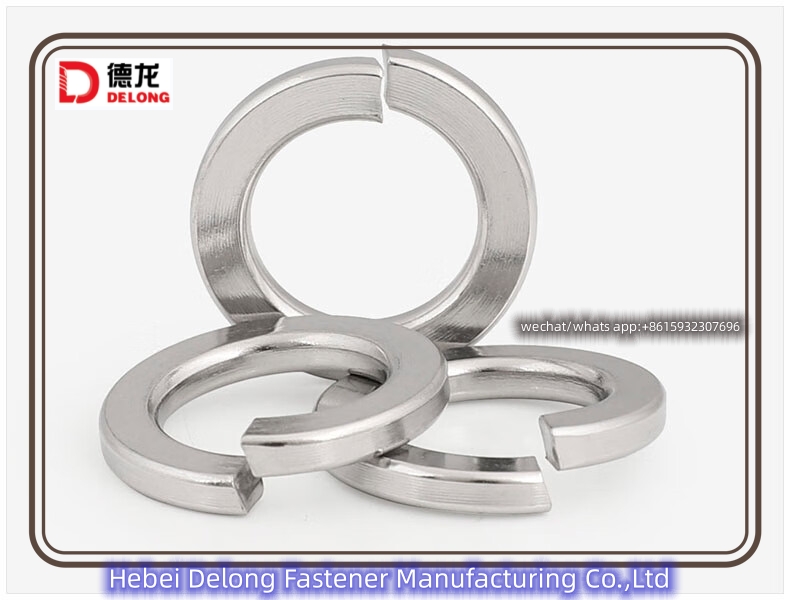

In a world driven by innovation and efficiency, the significance of reliable components such as spring washers cannot be understated. In 2016, the manufacturing sector witnessed a significant transformation, particularly in the production of spring washers. These essential components, integral to various mechanical systems, play a critical role in ensuring the longevity and reliability of machinery across multiple industries.

The Evolution and Importance of Spring Washer Manufacturing in 2016

The spring washer manufacturing process in 2016 underwent substantial advancements with the integration of new technologies. Traditional methods, which typically relied on manual processes and basic machinery, gradually transformed into automated production lines. Automation not only enhanced production efficiency but also improved quality control. Manufacturers began to adopt computerized systems for precision cutting, shaping, and finishing of spring washers, ensuring that each component met strict tolerances and standards.

5 16 spring washer factory

Moreover, material science advancements played a crucial role in evolving the characteristics of spring washers. Manufacturers explored new alloys and treatments that enhanced the strength, corrosion resistance, and fatigue life of these components. In 2016, materials like stainless steel and specialized coatings became increasingly popular, as they provided enhanced performance in harsh environments. This shift not only improved the reliability of spring washers but also expanded their application in diverse sectors such as automotive, aerospace, and construction.

The sustainability movement also gained traction in 2016, influencing the manufacturing processes of spring washers. Companies began to focus on eco-friendly practices, reducing waste, and maximizing resource efficiency. By implementing recycling programs and utilizing renewable energy sources, manufacturers aimed to minimize their carbon footprint while meeting the growing demand for environmentally responsible products.

Customer demand for customization in spring washer design also became a defining trend in 2016. Businesses sought tailored solutions to meet specific application requirements. This shift prompted manufacturers to invest in research and development, allowing them to offer a wider variety of sizes, shapes, and material compositions. The ability to provide bespoke spring washers not only increased customer satisfaction but also positioned manufacturers as leaders in a competitive market.

In conclusion, the spring washer manufacturing landscape in 2016 was marked by notable advancements in technology, material science, and sustainability practices. As industries continued to evolve, the role of spring washers as essential mechanical components grew more pronounced. The changes in manufacturing processes not only enhanced product quality and reliability but also paved the way for continued innovation in the years to come. As we look to the future, the lessons learned in 2016 will undoubtedly shape the trajectory of spring washer production and its critical place in various applications worldwide.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024