High-Quality Self Tapping Screws - 5, 16, 18 Sizes Available

The Rise of Self-Tapping Screws A Focus on 5% 2016-2018 Production Levels

Self-tapping screws have become integral components in various industries, particularly in construction, automotive manufacturing, and electronics. These specialized screws have the ability to tap their own holes in materials such as metal and plastic, making them a preferred choice for many applications. Between 2016 and 2018, the production of self-tapping screws experienced significant changes, with a notable increase of 5% during this period. This article explores the factors contributing to this growth and the implications for manufacturers and industries reliant on these fastening solutions.

The Rise of Self-Tapping Screws A Focus on 5% 2016-2018 Production Levels

Moreover, the automotive industry also played a crucial role in this growth. With the advent of electric vehicles (EVs) and advancements in automotive design, manufacturers increasingly sought lightweight materials. Self-tapping screws are designed to work effectively with these materials, ensuring that vehicles remain sturdy while benefiting from reduced weight. This evolution in automotive engineering further fueled demand for self-tapping screws during this period.

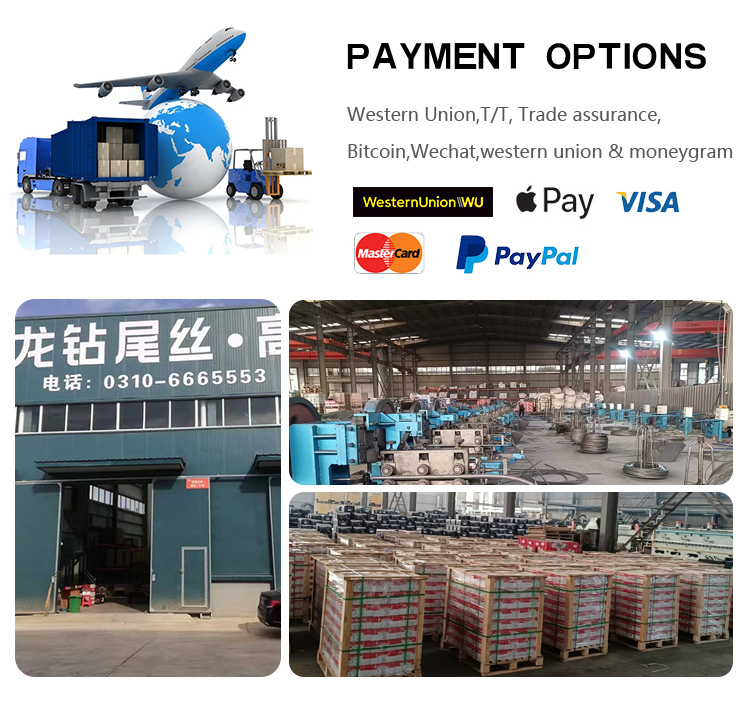

5 16 18 self tapping screw factory

Innovation within the manufacturing sector significantly contributed to the increased production levels. Advances in screw design, material quality, and production techniques led to improved performance characteristics, which attracted more users. Factories began investing in research and development to enhance the durability and efficiency of self-tapping screws. Sophisticated technologies such as CNC (Computer Numerical Control) machining allowed for precise manufacturing, resulting in higher-quality products that satisfied the growing market demands.

Furthermore, the global trade environment facilitated access to various international markets. Manufacturers of self-tapping screws expanded their reach, exporting to regions experiencing their own construction booms. Countries in Asia, Africa, and Eastern Europe emerged as key markets, increasing the global consumption of self-tapping screws by extensive margins. This international demand catalyzed production growth as factories ramped up their output to avoid supply shortages.

As we move beyond this growth period, manufacturers must continue to adapt to changing market dynamics. Sustainability trends are becoming increasingly important, leading to a push for eco-friendly materials and production practices. Companies that innovate in sustainable practices are likely to gain a competitive edge in the market. The industry could also benefit from integrating digital technologies, such as inventory management systems, to optimize production and ensure timely delivery.

In conclusion, the rise of self-tapping screws between 2016 and 2018, marked by a 5% increase in production, highlights the critical role these fasteners play across various sectors. Driven by construction and automotive demands, manufacturing innovations, and global market expansion, the future of self-tapping screws appears robust. Firms that continue to invest in quality improvements and sustainable practices will not only thrive but also advance the industry as a whole.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024