Feb . 10, 2025 09:32

Back to list

4 40 self tapping screw

In the world of fastening elements, the 4 40 self-tapping screw stands out as a versatile and crucial component for countless applications. Renowned for their durability and precision, these screws provide an excellent solution for projects requiring secure and reliable fastening without the need for pre-drilled holes.

Authoritative voices in the industry, such as manufacturing engineers and materials scientists, continuously highlight the importance of the screw design, particularly the threading angle and pitch, which significantly influence performance. Studies have shown that small variations in these parameters can lead to differences in torque requirements and holding strength, proving valuable information for those designing assemblies demanding precise specifications. Trust in the reliability of the 4 40 self-tapping screw is supported by its widespread use in critical applications, from securing mission-critical aerospace components to daily consumer electronics. Manufacturers with a proven track record, backed by quality certifications, further solidify their standing as trustworthy suppliers of these essential fasteners. This confidence allows buyers to rely on third-party evaluations and certifications to ensure they are acquiring a product that meets rigorous standards. Finally, the decision to use self-tapping screws should always consider the environmental impact. Innovations in manufacturing processes have led to the creation of self-tapping screws that utilize sustainable materials and coatings, reducing carbon footprints while maintaining performance. These advancements reflect a growing industry trend toward responsible production that does not compromise on quality or functionality. In conclusion, the 4 40 self-tapping screw is not merely a fastener but an innovation that combines engineering prowess with practical utility. Its role in modern assembly reflects the continuous commitment to evolve with the complexities of today’s technological landscape, ensuring both reliability and efficiency for any project it undertakes.

Authoritative voices in the industry, such as manufacturing engineers and materials scientists, continuously highlight the importance of the screw design, particularly the threading angle and pitch, which significantly influence performance. Studies have shown that small variations in these parameters can lead to differences in torque requirements and holding strength, proving valuable information for those designing assemblies demanding precise specifications. Trust in the reliability of the 4 40 self-tapping screw is supported by its widespread use in critical applications, from securing mission-critical aerospace components to daily consumer electronics. Manufacturers with a proven track record, backed by quality certifications, further solidify their standing as trustworthy suppliers of these essential fasteners. This confidence allows buyers to rely on third-party evaluations and certifications to ensure they are acquiring a product that meets rigorous standards. Finally, the decision to use self-tapping screws should always consider the environmental impact. Innovations in manufacturing processes have led to the creation of self-tapping screws that utilize sustainable materials and coatings, reducing carbon footprints while maintaining performance. These advancements reflect a growing industry trend toward responsible production that does not compromise on quality or functionality. In conclusion, the 4 40 self-tapping screw is not merely a fastener but an innovation that combines engineering prowess with practical utility. Its role in modern assembly reflects the continuous commitment to evolve with the complexities of today’s technological landscape, ensuring both reliability and efficiency for any project it undertakes.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

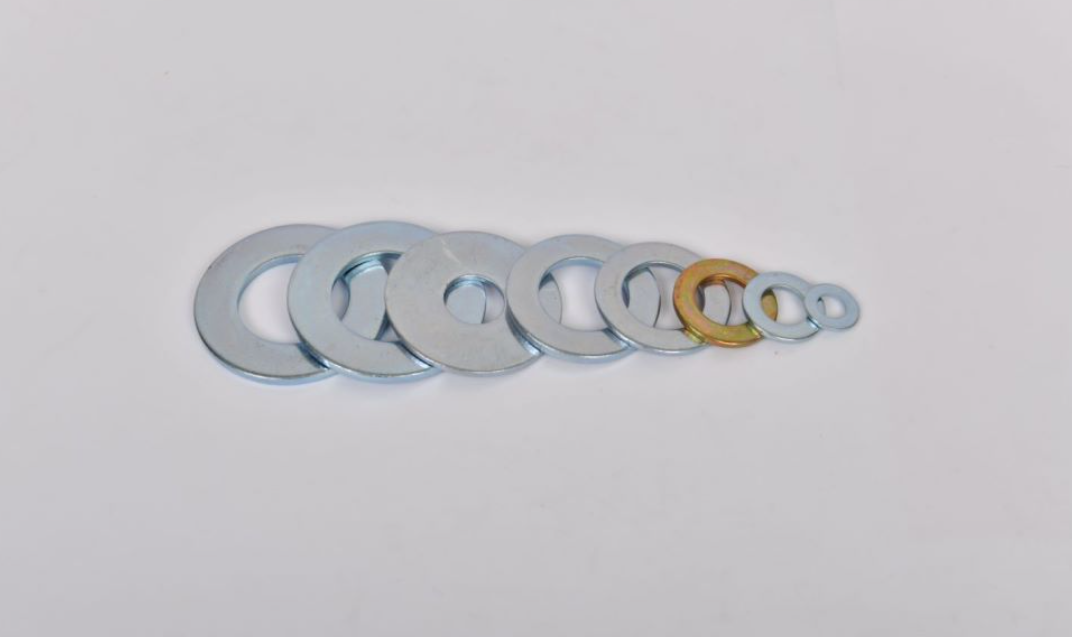

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News