Feb . 15, 2025 00:36

Back to list

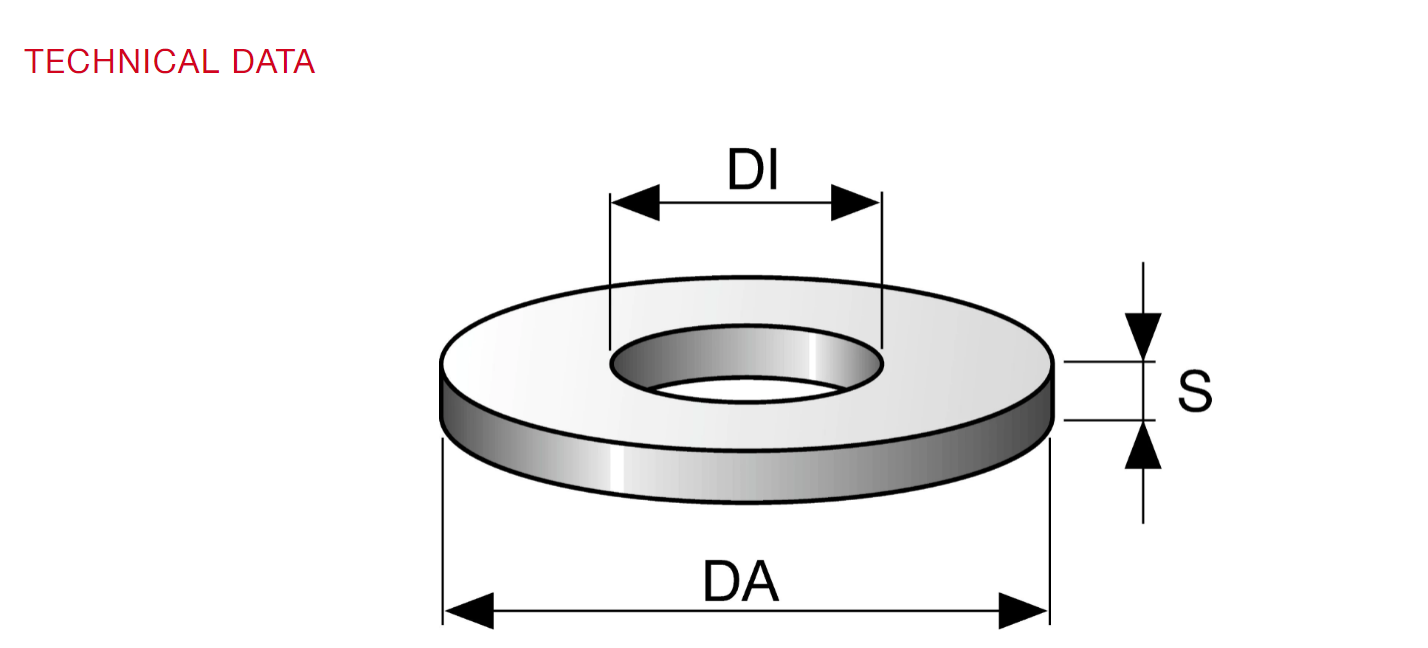

20mm flat washer

The 20mm flat washer, often perceived as a modest component in the vast world of hardware, plays a pivotal role far beyond its simplicity. Its expertise in providing essential support to threaded fasteners is indispensable across various industries, from automotive to construction and electronics. While small in size, its impact on the durability and efficiency of assemblies is profound, making it a component worthy of closer inspection.

Authoritativeness in the realm of 20mm flat washers is underscored by industry standards and guidelines that dictate their quality and application. Standards such as the ISO 7089/7090 provide specifications for dimensions and tolerances. These authoritative guidelines ensure that washers meet high-quality benchmarks necessary for safety and performance. Companies adhering to these standards often receive certification, adding an extra layer of reliability to their products. For professionals selecting components for critical applications, reliance on these standardized washers is a testament to their commitment to safety and quality assurance. Establishing trustworthiness in the selection of 20mm flat washers involves understanding the supplier's reputation and the product's traceability. Reputable suppliers often provide detailed product information, ensuring transparency in their manufacturing processes. Traceability guarantees that each washer can be tracked back to its source, which is crucial in industries where failure can have significant consequences. Testimonials and case studies from long-standing clients offer additional assurances of a supplier's commitment to quality. In conclusion, while the 20mm flat washer might appear to be a mere accessory in the hardware ensemble, its impact on the integrity and functionality of assemblies is irrefutable. Through a blend of experience, expertise, authoritativeness, and trustworthiness, this small component ensures that both domestic and industrial applications perform reliably over time. For anyone immersed in the fields requiring precision and durability, an insightful appreciation of the 20mm flat washer's role could be the difference between functional adequacy and optimal performance.

Authoritativeness in the realm of 20mm flat washers is underscored by industry standards and guidelines that dictate their quality and application. Standards such as the ISO 7089/7090 provide specifications for dimensions and tolerances. These authoritative guidelines ensure that washers meet high-quality benchmarks necessary for safety and performance. Companies adhering to these standards often receive certification, adding an extra layer of reliability to their products. For professionals selecting components for critical applications, reliance on these standardized washers is a testament to their commitment to safety and quality assurance. Establishing trustworthiness in the selection of 20mm flat washers involves understanding the supplier's reputation and the product's traceability. Reputable suppliers often provide detailed product information, ensuring transparency in their manufacturing processes. Traceability guarantees that each washer can be tracked back to its source, which is crucial in industries where failure can have significant consequences. Testimonials and case studies from long-standing clients offer additional assurances of a supplier's commitment to quality. In conclusion, while the 20mm flat washer might appear to be a mere accessory in the hardware ensemble, its impact on the integrity and functionality of assemblies is irrefutable. Through a blend of experience, expertise, authoritativeness, and trustworthiness, this small component ensures that both domestic and industrial applications perform reliably over time. For anyone immersed in the fields requiring precision and durability, an insightful appreciation of the 20mm flat washer's role could be the difference between functional adequacy and optimal performance.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News