Feb . 08, 2025 05:18

Back to list

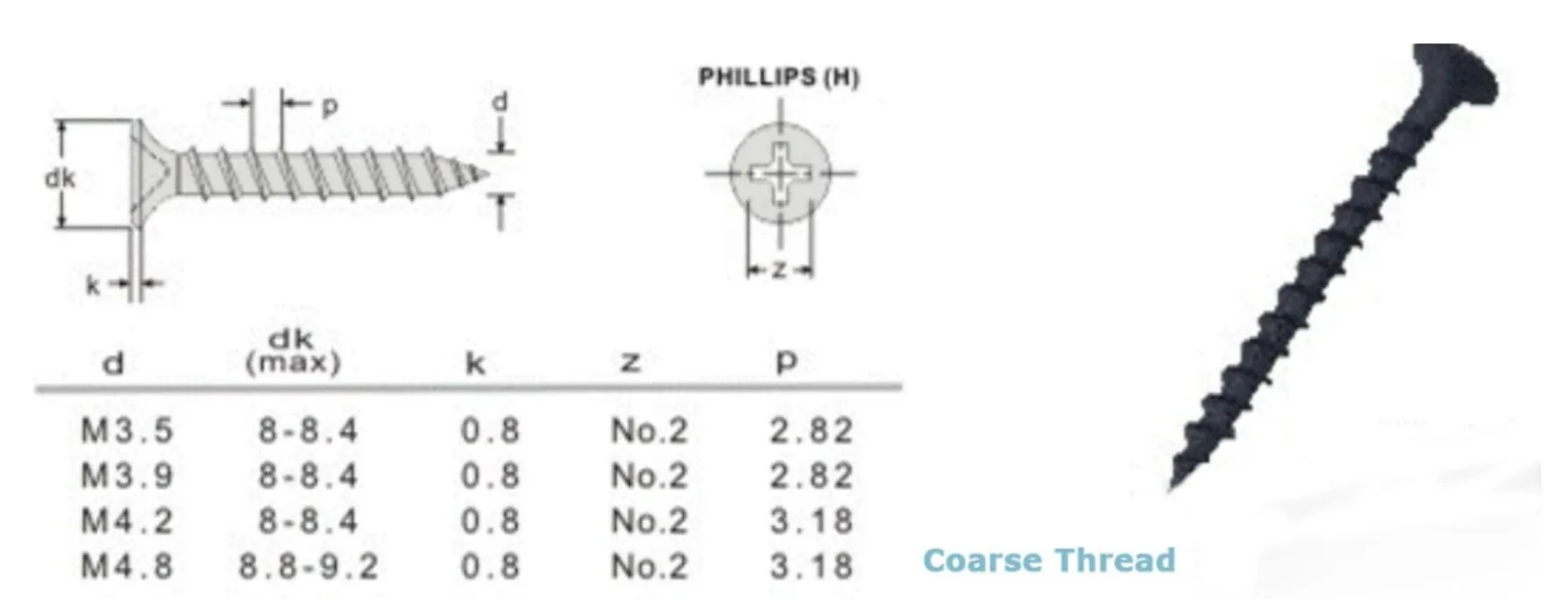

csk head self tapping screw

Selecting the right pilot hole size for self-tapping screws can significantly impact the quality and durability of your construction or DIY project. These screws, designed to tap their thread into the material, require precision in choosing the corresponding pilot hole size to ensure optimal functionality.

2. Metals For metals like aluminum or mild steel, a pilot hole at 75% of the thread’s minor diameter facilitates optimum engagement without distorting the threads or necessitating excessive torque. This adjustment is crucial because metals resist penetration more than wood, necessitating more aggressive thread engagement. 3. Plastics For plastic applications, where the material is more malleable and capable of expanding, the pilot hole size should hover around 70% of the screw’s root diameter. The innate elasticity of plastics allows them to form around the screw effectively, though precision here is key to preventing cracking or undue stress in the plastic. Furthermore, tapping into Experience and Expertise, professionals always rely on test-driving their selected pilot settings on scrap pieces of material before embarking on a project. This proactive approach detects potential sizing issues before they become a costly mistake. Adjustments in drill bit sizes or even screw selection can then be made without adverse effects on project timelines or budgets. Authoritativeness in this domain stems from adhering to manufacturer recommendations for both screws and materials. These guidelines often encapsulate industry-standard insights based on rigorous testing, ensuring not just adequate fastening but extending the longevity of the application. Finally, ensuring Trustworthiness in presenting these insights is vital. Aligning practical tips with verified manufacturer benchmarks not only builds confidence in the technique but assures project success, underpinning the user's trust in the chosen methodology. In essence, understanding the nuances of self-tapping screw pilot holes fortifies one's ability to execute projects with professional precision and superior outcomes. Whether working with wood, metal, or plastic, recognizing the interplay between screw, material, and intended application guarantees not just fastened integrity but the enduring success of the project.

2. Metals For metals like aluminum or mild steel, a pilot hole at 75% of the thread’s minor diameter facilitates optimum engagement without distorting the threads or necessitating excessive torque. This adjustment is crucial because metals resist penetration more than wood, necessitating more aggressive thread engagement. 3. Plastics For plastic applications, where the material is more malleable and capable of expanding, the pilot hole size should hover around 70% of the screw’s root diameter. The innate elasticity of plastics allows them to form around the screw effectively, though precision here is key to preventing cracking or undue stress in the plastic. Furthermore, tapping into Experience and Expertise, professionals always rely on test-driving their selected pilot settings on scrap pieces of material before embarking on a project. This proactive approach detects potential sizing issues before they become a costly mistake. Adjustments in drill bit sizes or even screw selection can then be made without adverse effects on project timelines or budgets. Authoritativeness in this domain stems from adhering to manufacturer recommendations for both screws and materials. These guidelines often encapsulate industry-standard insights based on rigorous testing, ensuring not just adequate fastening but extending the longevity of the application. Finally, ensuring Trustworthiness in presenting these insights is vital. Aligning practical tips with verified manufacturer benchmarks not only builds confidence in the technique but assures project success, underpinning the user's trust in the chosen methodology. In essence, understanding the nuances of self-tapping screw pilot holes fortifies one's ability to execute projects with professional precision and superior outcomes. Whether working with wood, metal, or plastic, recognizing the interplay between screw, material, and intended application guarantees not just fastened integrity but the enduring success of the project.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News