Self-Drilling Screw Solutions for Enhanced Efficiency and Reliability in 2014 Services

Understanding the Importance of 1% 204% 2014 Self-Drilling Screw Service

In today's fast-paced construction and manufacturing environments, efficiency and reliability are paramount. One of the unsung heroes of these sectors is the self-drilling screw. Often overlooked, self-drilling screws, particularly those conforming to specifications like 1% 204% 2014, play a critical role in ensuring that structures are secure, stable, and built to last.

Understanding the Importance of 1% 204% 2014 Self-Drilling Screw Service

The specifications 1% 204% 2014 highlight the standard of these screws, indicating their material composition and performance characteristics. Typically, these screws are crafted from high-quality steel, featuring coatings that provide corrosion resistance, thereby enhancing their longevity and durability. This is particularly important in environments exposed to moisture or extreme weather conditions, where rust and degradation can severely compromise the integrity of construction materials.

1 4 14 self drilling screw service

Moreover, the versatility of self-drilling screws makes them suitable for a wide range of applications. From fastening metal to metal or wood to metal in construction to acting as secure fasteners in appliances and automotive components, these screws play a crucial role across various industries. Their design allows for a strong hold that can withstand vibration and stress, making them ideal for both permanent and semi-permanent assemblies.

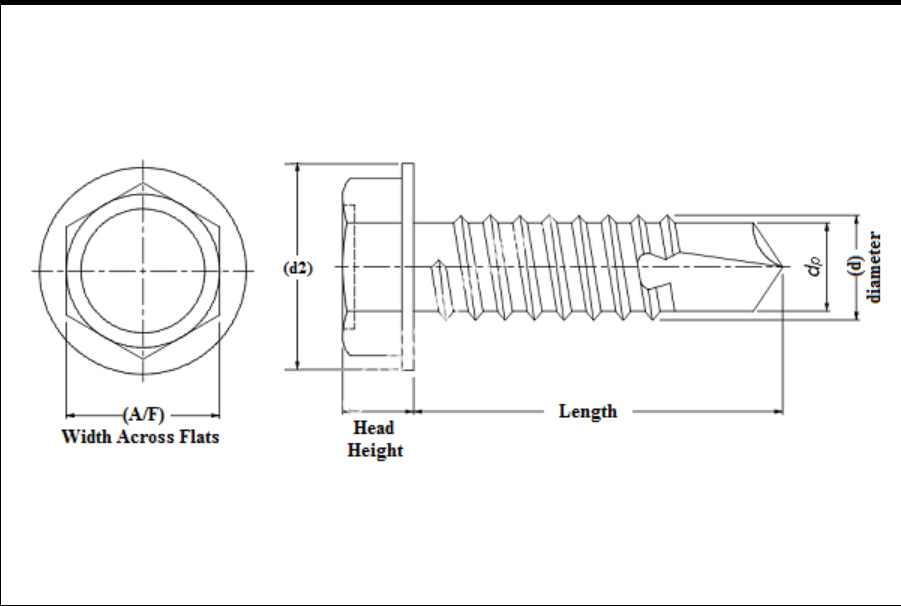

The service aspect of 1% 204% 2014 self-drilling screws cannot be underestimated. Manufacturers and suppliers often offer a variety of options, including different lengths, head types, and thread configurations, thereby catering to the specific needs of a project. Additionally, many companies provide technical support, such as installation guidance or advice on the best screw type for a particular application, ensuring that customers can make informed decisions.

It is also important to consider the environmental impact of using self-drilling screws. As the construction industry moves towards more sustainable practices, many manufacturers are seeking to produce screws using recycled materials and eco-friendly coatings. This helps reduce waste and promotes a greener approach to building and manufacturing.

In conclusion, 1% 204% 2014 self-drilling screws are an essential component in modern construction and manufacturing. Their unique design saves time and labor costs, while their robust specifications ensure a long-lasting, reliable connection. Through thoughtful service offerings and a commitment to sustainability, the industry continues to innovate and improve upon these vital fasteners. As building practices evolve, the importance of self-drilling screws will only grow, underscoring their significance in building our future.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024