1/4-20 Self Tapping Screw Hole Size Specification and Export Information

Understanding the 1/4-20 Self Tapping Screw Hole Size A Comprehensive Guide for Exporters

In today’s manufacturing landscape, the demand for precise fastening solutions is paramount. Among the various types of fasteners available, the 1/4-20 self-tapping screw has garnered significant attention for its versatility and effectiveness in a wide range of applications. For exporters looking to navigate the international market, understanding the specifications and hole size requirements of these screws is essential.

What is a 1/4-20 Self Tapping Screw?

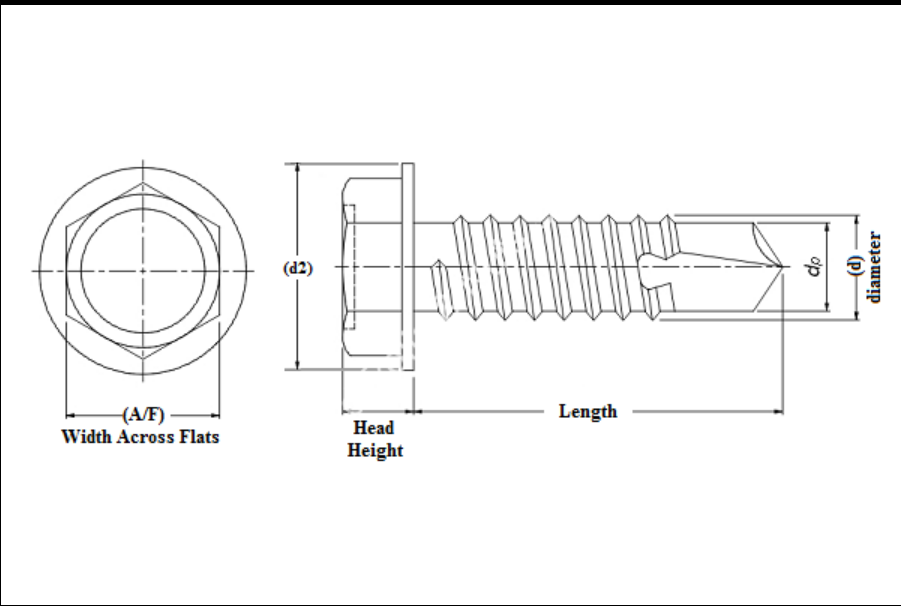

A 1/4-20 self-tapping screw is defined by its thread size and pitch. The “1/4” indicates the diameter of the screw in inches, while “20” denotes the number of threads per inch (TPI). This particular screw size is commonly used in various industrial and residential applications where a strong, secure fastener is required. Self-tapping screws can create their own nut when driven into materials like plastic or metal, thereby eliminating the need for pre-drilled holes in many scenarios.

One key advantage of using self-tapping screws is their ability to create threads in the material they are being driven into. This capability allows for quicker assembly times and reduces the overall material costs associated with additional fastening components.

Importance of Hole Size

For optimal performance, understanding the correct hole size for a 1/4-20 self-tapping screw is crucial. While self-tapping screws can create threads in materials, the size of the hole significantly impacts the screw's holding power and integrity. Incorrect hole sizes can lead to weak connections, which may compromise the longevity and safety of the assembly.

Typically, for a 1/4-20 self-tapping screw, a pilot hole is recommended, particularly when dealing with harder materials such as metal. The pilot hole should generally be smaller than the screw's outer diameter, providing enough material for the threads to grip without overtightening and risking material failure.

For instance, the recommended pilot hole size for a 1/4-20 screw in harder materials is often around 0.200 inches (5.08 mm). This ensures that when the screw is driven in, it can effectively cut its own path without excessive force that might fracture or damage the surrounding structure.

1/4-20 self tapping screw hole size exporter

In softer materials, however, such as wood or softer plastics, the hole can be somewhat larger, sometimes around 0.250 inches (6.35 mm). This allows for easier insertion while still ensuring a tight fit.

Factors Influencing Hole Size Selection

When determining the appropriate hole size for 1/4-20 self-tapping screws, several factors must be considered

1. Material Type The hardness and tensile strength of the material being fastened should dictate the hole size. Softer materials may require larger holes, while harder materials necessitate tighter tolerances.

2. Screw Length The length of the screw selected will also influence hole size. A longer screw may require a deeper pilot hole, ensuring adequate engagement with the material for a robust connection.

3. Load Requirements The application’s load requirements will affect the decision as well. Heavier loads often necessitate tighter tolerances and a precise fit to ensure the assembly can withstand stress without failure.

4. Environment Consideration of the environment in which the assembly will function is also crucial. Exposure to moisture, temperature fluctuations, or corrosive substances can alter the necessary specifications for hole size and screw type.

Conclusion

In conclusion, the 1/4-20 self-tapping screw represents a reliable and efficient fastening solution for a variety of industrial and DIY projects. Exporters must pay close attention to the appropriate hole sizes and related factors to ensure optimal performance and customer satisfaction. By understanding the nuances of screw types, particularly in relation to their application and material, exporters can enhance their offerings and build a reputation for quality in the global marketplace. Ensuring that your products meet the specified standards will ultimately lead to stronger connections and a more successful export business.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024