Feb . 08, 2025 02:56

Back to list

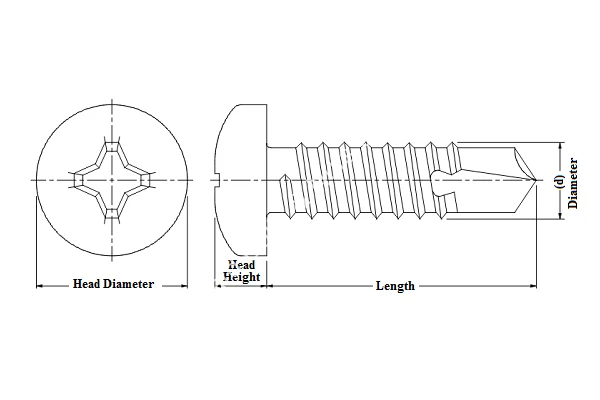

12 self tapping screw diameter

Navigating the world of self-tapping screws can seem daunting, especially for those new to the field of construction or DIY projects. Understanding the intricacies of screw diameters and their applications is essential to ensure project success and structural integrity. The diameter of a screw not only determines its holding power but also affects the ease of installation and the type of materials it is best suited for. Here's a comprehensive insight into the importance of choosing the correct diameter when working with 12 self-tapping screws.

Apart from these practical considerations, quality and coating of the screw also influence its efficacy. Opting for screws with a corrosion-resistant coating can prevent rust, especially in outdoor or moisture-prone conditions. This prolongs the life of the screw and maintains the structural integrity of the assembly. Another often overlooked factor is the screw's threading. Coarse-threaded screws are suitable for soft materials, thanks to their ability to grip effectively without causing damage, while fine-threaded screws are preferable for metals, given their capacity to secure tightly and hold under pressure. For professionals and DIY enthusiasts alike, trusting a supplier known for quality and reliability is indispensable. Brands that provide comprehensive product information, detailed user guides, and material compatibility charts can significantly aid in the selection process. This enhances the screw’s effectiveness and ensures project success, reflecting positively on the user's expertise. A tangible case in point involves metal roofing installations, a common application for No. 12 self-tapping screws. It demands not only precision but also products that can withstand environmental stressors. Selecting the correct diameter and understanding the nuances of the installation can mean the difference between enduring success and project failure. In conclusion, the selection of a 12 self-tapping screw involves a detailed understanding of its diameter, material compatibility, and the specific demands of your project. By considering these factors, you ensure not just the success of your current project, but also bolster your credibility and trust as a professional or an adept DIY enthusiast. This nuanced approach to choosing screws builds a foundation of expertise, reinforcing the user's authoritative position in handling self-tapping screws for varied applications. Such informed decisions solidify trust not only in the tools used but also in the person wielding them.

Apart from these practical considerations, quality and coating of the screw also influence its efficacy. Opting for screws with a corrosion-resistant coating can prevent rust, especially in outdoor or moisture-prone conditions. This prolongs the life of the screw and maintains the structural integrity of the assembly. Another often overlooked factor is the screw's threading. Coarse-threaded screws are suitable for soft materials, thanks to their ability to grip effectively without causing damage, while fine-threaded screws are preferable for metals, given their capacity to secure tightly and hold under pressure. For professionals and DIY enthusiasts alike, trusting a supplier known for quality and reliability is indispensable. Brands that provide comprehensive product information, detailed user guides, and material compatibility charts can significantly aid in the selection process. This enhances the screw’s effectiveness and ensures project success, reflecting positively on the user's expertise. A tangible case in point involves metal roofing installations, a common application for No. 12 self-tapping screws. It demands not only precision but also products that can withstand environmental stressors. Selecting the correct diameter and understanding the nuances of the installation can mean the difference between enduring success and project failure. In conclusion, the selection of a 12 self-tapping screw involves a detailed understanding of its diameter, material compatibility, and the specific demands of your project. By considering these factors, you ensure not just the success of your current project, but also bolster your credibility and trust as a professional or an adept DIY enthusiast. This nuanced approach to choosing screws builds a foundation of expertise, reinforcing the user's authoritative position in handling self-tapping screws for varied applications. Such informed decisions solidify trust not only in the tools used but also in the person wielding them.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News