Feb . 07, 2025 00:55

Back to list

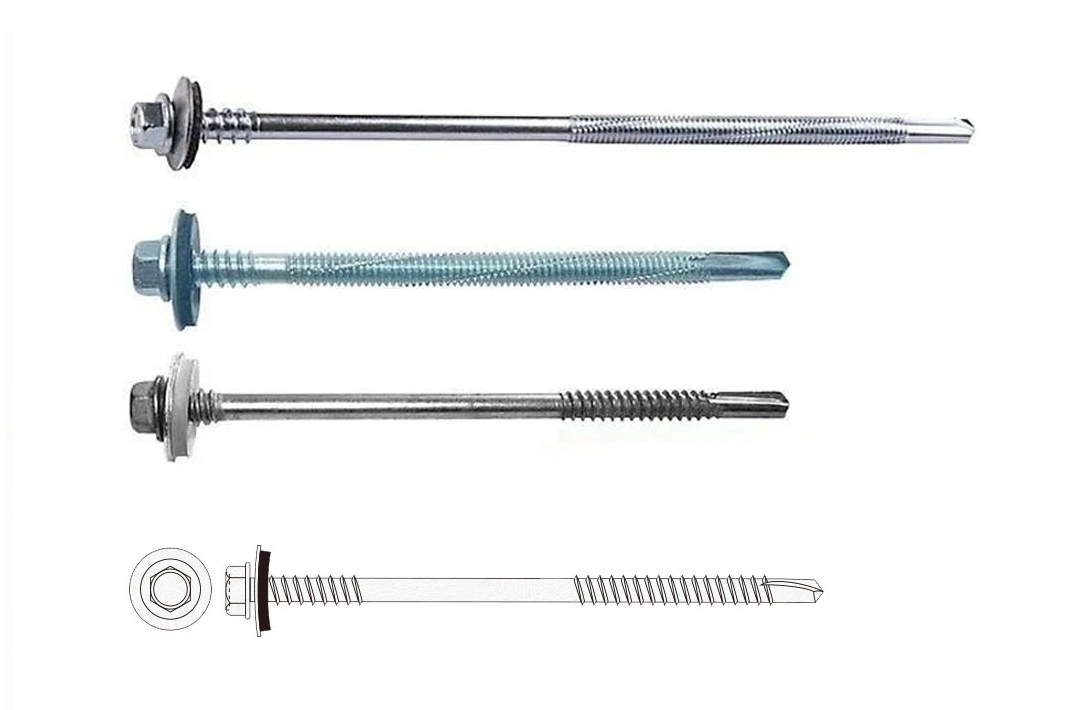

12 self tapping screw

Navigating the world of fasteners, a frequent mention is the 12 self tapping screw. Its diverse application across various industries speaks volumes about its significance. This article delves into its features, uses, and advantages, bringing forward a trustworthy, authoritative perspective with professional expertise.

In woodworking, the utility of the 12 self tapping screw cannot be overstated. Traditional wood screws require pilot holes, an additional step that is time-consuming and demands accuracy. However, self tapping screws negate this requirement, making them an efficient choice for furniture assembly and cabinetry. Their sharp cutting threads are adept at cutting through wood grain without causing splits, ensuring a smooth and secure fit. The trustworthiness of these screws extends beyond their mechanical attributes to include their compliance with industry standards. Many manufacturers adhere to ISO certifications, reinforcing their credibility and reliability customers expect. This compliance also facilitates their use in regulated industries where adherence to stringent safety standards is mandatory. A vital consideration when selecting these screws is the diameter and thread type, which must be appropriate for the material and the intended load. A mismatch can lead to weakened connections or damage. Hence, expertise in choosing the right screw based on material and application is crucial. Emerging trends in fastener technology continue to enhance the capabilities of the 12 self tapping screw. Innovations such as self-healing materials and advanced coatings for friction reduction are on the horizon, promising even greater performance. In conclusion, the 12 self tapping screw stands out as a paragon of engineering prowess. Its extensive application across industries is testament to its design and functionality. As industries evolve and demands for efficiency and reliability increase, these screws will undoubtedly remain a staple, trusted by professionals for their expert design and authoritative performance. Whether you’re a seasoned engineer or a DIY enthusiast, understanding and utilizing these screws can lead to significant improvements in your projects.

In woodworking, the utility of the 12 self tapping screw cannot be overstated. Traditional wood screws require pilot holes, an additional step that is time-consuming and demands accuracy. However, self tapping screws negate this requirement, making them an efficient choice for furniture assembly and cabinetry. Their sharp cutting threads are adept at cutting through wood grain without causing splits, ensuring a smooth and secure fit. The trustworthiness of these screws extends beyond their mechanical attributes to include their compliance with industry standards. Many manufacturers adhere to ISO certifications, reinforcing their credibility and reliability customers expect. This compliance also facilitates their use in regulated industries where adherence to stringent safety standards is mandatory. A vital consideration when selecting these screws is the diameter and thread type, which must be appropriate for the material and the intended load. A mismatch can lead to weakened connections or damage. Hence, expertise in choosing the right screw based on material and application is crucial. Emerging trends in fastener technology continue to enhance the capabilities of the 12 self tapping screw. Innovations such as self-healing materials and advanced coatings for friction reduction are on the horizon, promising even greater performance. In conclusion, the 12 self tapping screw stands out as a paragon of engineering prowess. Its extensive application across industries is testament to its design and functionality. As industries evolve and demands for efficiency and reliability increase, these screws will undoubtedly remain a staple, trusted by professionals for their expert design and authoritative performance. Whether you’re a seasoned engineer or a DIY enthusiast, understanding and utilizing these screws can lead to significant improvements in your projects.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News