1/2 flat washer7 exporter

The Importance of 1/2% Flat Washer in Industrial Applications

In the realm of mechanical engineering and construction, components like washers play a critical role in ensuring the integrity and functionality of various assemblies. Among these components, the flat washer, particularly the 1/2% flat washer, has gained significant attention. This article delves into the specifications, applications, and benefits of the 1/2% flat washer while also discussing the role of exporters in the global supply chain.

Understanding the 1/2% Flat Washer

A flat washer is a thin, circular piece of metal with a hole in the center that is primarily used to distribute the load of a threaded fastener, such as a screw or bolt. The term 1/2% refers to the diameter of the washer, which is approximately half an inch, a common size in various applications. Made from materials such as stainless steel, carbon steel, or other alloys, these washers come in different thicknesses and finishes, catering to diverse industrial requirements.

Applications and Benefits

The versatility of the 1/2% flat washer is evident in its wide range of applications. One of its primary functions is to prevent damage to the surface being fastened. When a bolt or screw is tightened, it can exert significant pressure on the surface material, potentially leading to deformation. A flat washer serves to distribute this pressure, thereby minimizing the risk of damage.

Moreover, flat washers can enhance the overall strength of an assembly. By providing additional surface area, they help to create a more secure fastening. This is especially crucial in applications where vibrations are present, such as in automotive or aerospace industries. In such environments, washers can mitigate the risk of loosening due to constant movement.

1/2 flat washer7 exporter

In addition to providing support, flat washers also serve to protect against corrosion. For instance, when utilized alongside stainless steel fasteners, a flat washer can prevent galvanic corrosion, a reaction that occurs when two different metals come into contact in the presence of an electrolyte. In this way, using the right type of washer can extend the lifespan of fastening assemblies, reducing maintenance costs over time.

The Role of Exporters in the Global Supply Chain

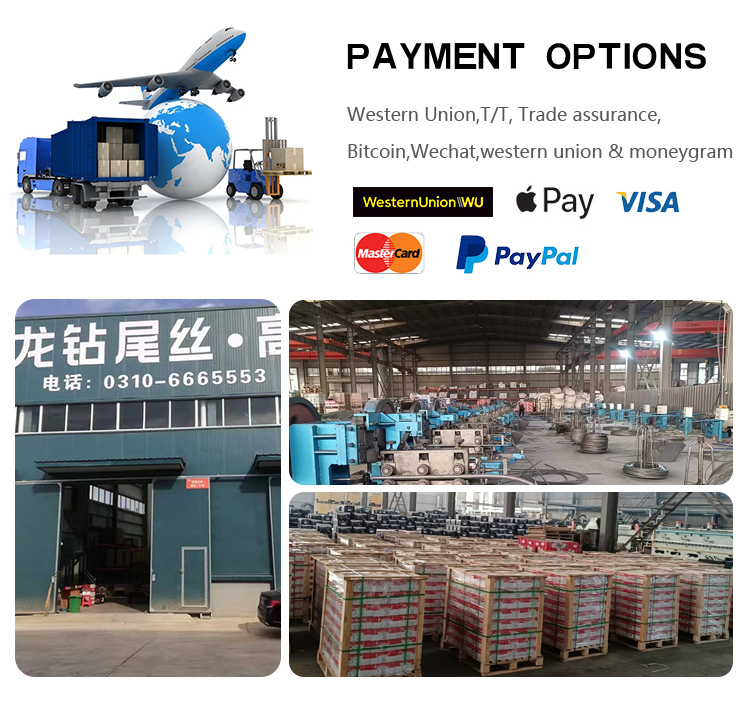

As industries continue to grow and evolve, so does the demand for quality components like the 1/2% flat washer. This growing demand has propelled a significant market for exporters who specialize in the manufacturing and distribution of industrial fasteners and components. Exporters play a vital role in ensuring that various industries have access to high-quality products regardless of geographic boundaries.

These exporters often focus on maintaining stringent quality control measures to ensure that their products meet international standards. They source materials from reliable suppliers and invest in advanced manufacturing technologies to produce washers that are durable, efficient, and suitable for a wide range of applications.

Additionally, exporters facilitate trade by navigating complex regulations and logistics, ensuring that products are delivered timely and efficiently to various parts of the world. They also provide valuable expertise in materials selection, helping clients choose the best products suited to their specific needs, further contributing to the success of various industrial projects.

Conclusion

The 1/2% flat washer plays an indispensable role in a multitude of mechanical and construction applications. Its ability to distribute load, prevent surface damage, and enhance assembly strength makes it a vital component across diverse industries. As the demand for high-quality flat washers continues to rise, exporters will remain crucial players in the supply chain, ensuring that industries have access to the products needed for efficiency and safety. Through their commitment to quality and service, they contribute significantly to the overall success of industrial operations worldwide.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024