Feb . 08, 2025 01:24

Back to list

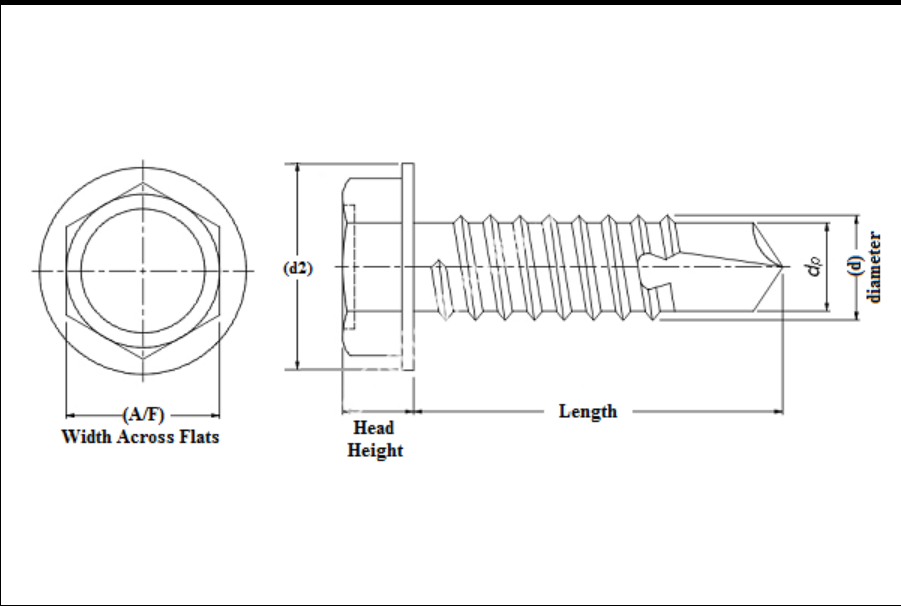

10x1 self tapping screw

The 10x1 self-tapping screw, an indispensable tool in the world of construction and home improvement, stands out for its impressive efficacy in fastening applications. These screws are designed to create their own threads as they are driven into materials such as metal, wood, and plastic, eliminating the need for a pre-drilled hole. The process of mastering their use involves understanding their specifications, benefits, and the scenarios where they offer the most value.

Trustworthiness in a fastener is paramount and the 10x1 self-tapping screw delivers through rigorous manufacturing standards and quality control measures. High-grade alloys and precision engineering ensure these screws can withstand significant stress and torque without failing. This reliability makes them a favored choice among professionals who require assurance that their work will withstand the test of time and elements. The self-tapping screw market continuously evolves, embracing technological advancements. Recent innovations have introduced coatings that further enhance corrosion resistance, and thread designs that improve performance in specific materials, broadening the scope of applications. Furthermore, manufacturers are increasingly focusing on sustainability, utilizing recycled metals and eco-friendly production processes. Experience gathered from extensive use reveals that while the 10x1 self-tapping screw is a straightforward tool, its applications are manifold. A professional must consider the specific requirements of the task at hand, such as material density, environmental conditions, and aesthetic expectations before choosing a screw type. In environments where speed and efficiency are prioritized, these screws offer unparalleled convenience, negating the need for multiple tools and steps. As a product, it encapsulates the blend of engineering precision and practical application, making it a valuable ally in diverse projects. Whether in constructing durable frameworks or assembling intricate gadgets, the 10x1 self-tapping screw proves its mettle time and again. Its continued relevance in modern construction and assembly speaks volumes about its design efficacy and reliability, ensuring it remains a staple in toolkits across industries.

Trustworthiness in a fastener is paramount and the 10x1 self-tapping screw delivers through rigorous manufacturing standards and quality control measures. High-grade alloys and precision engineering ensure these screws can withstand significant stress and torque without failing. This reliability makes them a favored choice among professionals who require assurance that their work will withstand the test of time and elements. The self-tapping screw market continuously evolves, embracing technological advancements. Recent innovations have introduced coatings that further enhance corrosion resistance, and thread designs that improve performance in specific materials, broadening the scope of applications. Furthermore, manufacturers are increasingly focusing on sustainability, utilizing recycled metals and eco-friendly production processes. Experience gathered from extensive use reveals that while the 10x1 self-tapping screw is a straightforward tool, its applications are manifold. A professional must consider the specific requirements of the task at hand, such as material density, environmental conditions, and aesthetic expectations before choosing a screw type. In environments where speed and efficiency are prioritized, these screws offer unparalleled convenience, negating the need for multiple tools and steps. As a product, it encapsulates the blend of engineering precision and practical application, making it a valuable ally in diverse projects. Whether in constructing durable frameworks or assembling intricate gadgets, the 10x1 self-tapping screw proves its mettle time and again. Its continued relevance in modern construction and assembly speaks volumes about its design efficacy and reliability, ensuring it remains a staple in toolkits across industries.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News