Feb . 19, 2025 02:52

Back to list

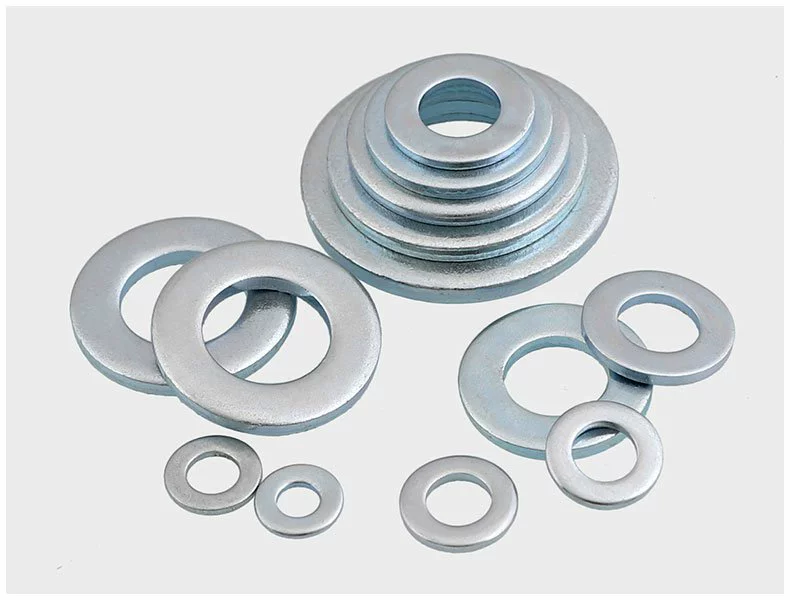

10mm spring washer

The world of fastening solutions is vast and sometimes complex, yet one essential component stands out for its simplicity and effectiveness the 10mm spring washer. This small but mighty piece of hardware plays a crucial role in ensuring the integrity and durability of various mechanical assemblies.

Understanding the mechanics of how a spring washer functions underpins its authoritativeness as a fastening solution. The washer operates by exerting a continuous load on the fastened components, effectively increasing the friction at the joint surfaces. This additional friction combats any tendency for the bolt or nut to rotate, which is the primary cause of loosening under dynamic conditions. Trustworthiness is a foundational quality that cannot be overlooked when discussing the utilization of 10mm spring washers. Manufacturers of high-performance machinery or critical infrastructure ensure their designs incorporate high-quality washers that meet rigorous industry standards. Certifications from organizations like the International Organization for Standardization (ISO) further verify that 10mm spring washers have undergone stringent testing for durability and performance. The real-world validation of the 10mm spring washer lies within field applications and customer satisfaction. Engineers report significant decreases in maintenance costs and downtime due to the reliability of lock washers in securing assemblies. For instance, in the wind energy sector, turbines experience a wide range of stresses due to wind loads and mechanical operation. The 10mm spring washer ensures that the components within these turbines remain secure, ultimately contributing to the longevity and efficiency of the energy production process. In conclusion, the 10mm spring washer is a fundamental component in the arsenal of mechanical fasteners. Its effectiveness lies in its simplicity, backed by a history of success across various industries. Expertise in selecting the appropriate material and understanding its application environment further enhances its utility. Moreover, the credibility provided by industry standards and the washer's proven reliability solidify its position as an indispensable tool in modern engineering. Whether in a high-speed racing car, a skyscraper construction, or a backyard DIY project, the 10mm spring washer remains a steadfast guardian, ensuring the security and longevity of mechanical assemblies.

Understanding the mechanics of how a spring washer functions underpins its authoritativeness as a fastening solution. The washer operates by exerting a continuous load on the fastened components, effectively increasing the friction at the joint surfaces. This additional friction combats any tendency for the bolt or nut to rotate, which is the primary cause of loosening under dynamic conditions. Trustworthiness is a foundational quality that cannot be overlooked when discussing the utilization of 10mm spring washers. Manufacturers of high-performance machinery or critical infrastructure ensure their designs incorporate high-quality washers that meet rigorous industry standards. Certifications from organizations like the International Organization for Standardization (ISO) further verify that 10mm spring washers have undergone stringent testing for durability and performance. The real-world validation of the 10mm spring washer lies within field applications and customer satisfaction. Engineers report significant decreases in maintenance costs and downtime due to the reliability of lock washers in securing assemblies. For instance, in the wind energy sector, turbines experience a wide range of stresses due to wind loads and mechanical operation. The 10mm spring washer ensures that the components within these turbines remain secure, ultimately contributing to the longevity and efficiency of the energy production process. In conclusion, the 10mm spring washer is a fundamental component in the arsenal of mechanical fasteners. Its effectiveness lies in its simplicity, backed by a history of success across various industries. Expertise in selecting the appropriate material and understanding its application environment further enhances its utility. Moreover, the credibility provided by industry standards and the washer's proven reliability solidify its position as an indispensable tool in modern engineering. Whether in a high-speed racing car, a skyscraper construction, or a backyard DIY project, the 10mm spring washer remains a steadfast guardian, ensuring the security and longevity of mechanical assemblies.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News