Exploring Dimensions and Specifications of 10 Percent Flat Washer Manufacturing in Factories

Understanding 10% Flat Washer Dimensions A Comprehensive Guide

Flat washers are essential hardware components used in various mechanical assemblies and construction applications. They serve crucial roles by distributing load, reducing friction, and preventing damage to surfaces during fastening. Among the myriad types of washers available, the 10% flat washer is a specific category that often garners attention due to its unique dimensions and applications. In this article, we will delve into the dimensions of 10% flat washers, their manufacturing process, and their benefits.

What Are 10% Flat Washers?

A flat washer is a thin, circular plate with a hole in the center that is used to support or distribute the load of a threaded fastener. The “10%” designation typically refers to the nominal thickness of the washer, which is generally around 10% of its outer diameter. This thickness plays a vital role in determining the washer's load distribution capabilities and overall performance in an assembly.

Dimensions of 10% Flat Washers

The dimensions of 10% flat washers can vary depending on the specific application and manufacturer standards. However, some common dimensions are generally accepted within the industry. For instance, if we consider a washer with an outer diameter (OD) of 100 mm, the typical thickness would be approximately 10 mm. This ratio remains consistent across various sizes, making it easier for engineers and manufacturers to select the right washer for their needs.

To provide a clearer understanding, let's break down the dimensions further

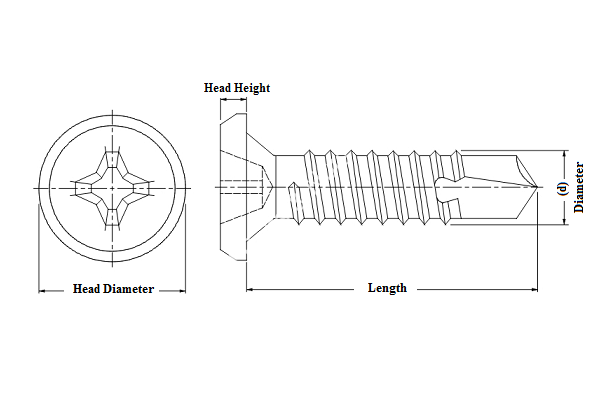

1. Outer Diameter (OD) This is the total diameter of the washer. It directly influences the load distribution area. 2. Inner Diameter (ID) The hole in the center must accommodate the specific size of the bolt or screw being used. For example, a washer designed for a 10 mm bolt will have an ID slightly larger than 10 mm to allow for easy installation.

3. Thickness (T) As noted, this is typically 10% of the OD. It is crucial for preventing the washer from deforming under load and ensuring that it maintains its shape during installation.

4. Material The choice of material can also affect the dimensions of the washer. Common materials include stainless steel, carbon steel, and aluminum, each offering different benefits in terms of strength, corrosion resistance, and weight.

10 flat washer dimensions factories

The Manufacturing Process

Manufacturing 10% flat washers involves several steps to ensure precision and quality. The process typically starts with selecting the appropriate material, followed by cutting sheets into smaller discs. These discs are then punched to create the central hole.

Next, washers undergo processes like heat treatment and surface finishing to enhance their durability and resistance to corrosion. Advanced manufacturing techniques, such as CNC machining or stamping, are often used to achieve exact dimensions and tolerances that meet industry standards.

Benefits of Using 10% Flat Washers

1. Load Distribution 10% flat washers effectively distribute the load from the fastener over a larger area, reducing the risk of damaging the surfaces they are applied to.

2. Surface Protection They minimize friction between surfaces, preventing wear and tear, which can prolong the life of both the fastener and the materials being connected.

3. Versatility With their standardized dimensions, they can be used in numerous applications across various industries, including automotive, construction, and manufacturing.

4. Ease of Installation The consistency in dimensions and material properties allows for easier installation with threaded fasteners, contributing to efficient assembly processes.

Conclusion

In summary, 10% flat washers are critical components in the world of fastening and assembly. Understanding their dimensions and manufacturing processes is essential for engineers, manufacturers, and DIY enthusiasts alike. By selecting the appropriate washer, one can ensure safety, efficiency, and longevity in mechanical systems. Whether you are working on a small project at home or large-scale industrial applications, considering the specifics of 10% flat washer dimensions will undoubtedly contribute to better results.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024