Feb . 07, 2025 04:31

Back to list

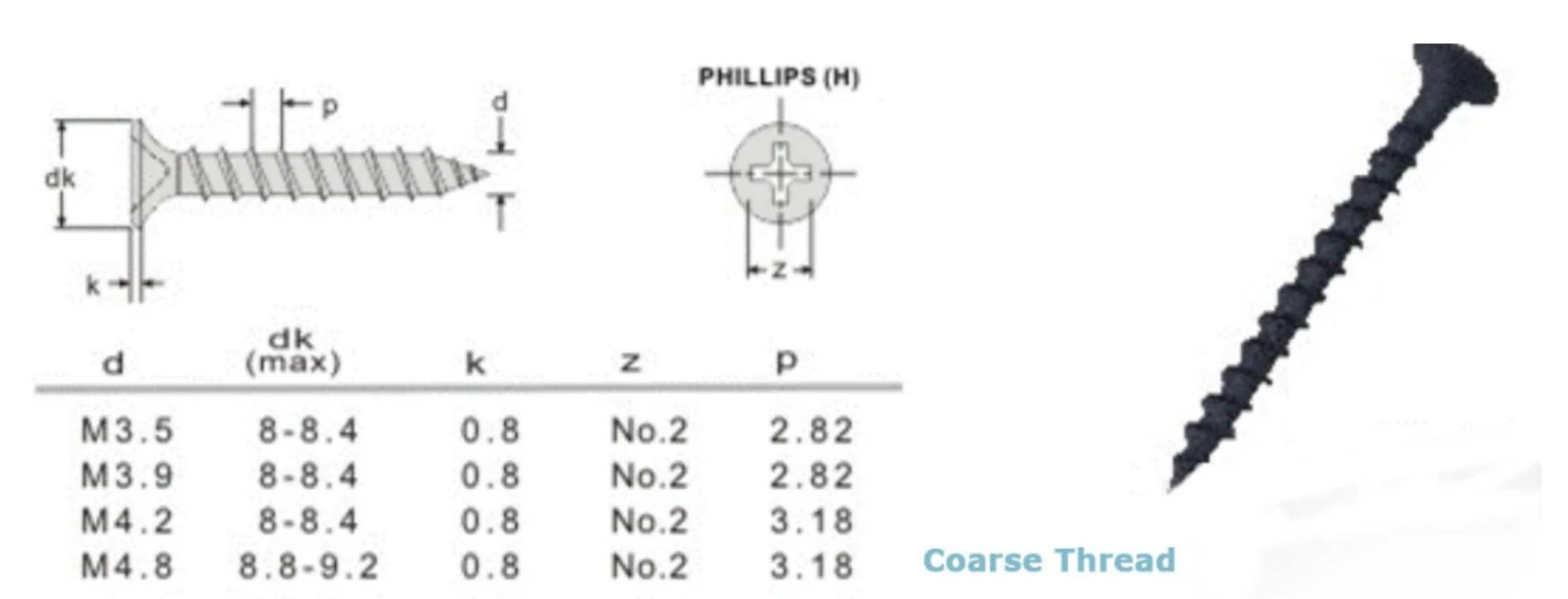

YZP CHIPBOARD SCREW

When embarking on a project that necessitates precision and durability, the 10 32 self-tapping screw often becomes an essential component. This specific screw has gained significant trust among professionals and hobbyists alike due to its unique ability to create its own threads in various materials, ranging from metals to plastics. Its self-tapping capability not only streamlines installation but also enhances the structural integrity of assembled components, making it invaluable in diverse applications.

Trustworthiness is a cornerstone of product reliability, and the 10 32 self-tapping screw excels in this domain. Users often express their confidence in these screws due to their consistent performance. They are widely available, ensuring that replacement and maintenance are straightforward if necessary. Furthermore, detailed product specifications and certifications from recognized bodies provide an additional layer of assurance regarding their quality and safety. For the conscientious professional or enthusiast, selecting the 10 32 self-tapping screw is not merely about securing two pieces of material together, but rather about ensuring that the connection is uncompromised and enduring. Whether for applications requiring frequent disassembly and reassembly or for permanent fixes, these screws have proven their mettle time and again. The guide to utilizing these screws optimally involves understanding both the mechanical properties of the screw and the material to which it is being affixed. Careful attention to aligning screws perpendicular to the surface and applying consistent, appropriate force are critical steps to preventing stripping and ensuring a smooth tapping process. Moreover, using high-quality driver tools enhances the precision and efficiency of installation, confirming a flawless finish. Ultimately, the 10 32 self-tapping screw stands as a reliable tool in the arsenal of fastening solutions. Its ability to provide sturdy, dependable connections across diverse materials and contexts makes it indispensable. By embodying experience, demonstrating expertise, earning recognition, and maintaining trust, these screws offer a blend of functionality, efficiency, and reliability that is unmatched. With their adoption, whether in professional setups or DIY projects, the results invariably meet and often surpass expectations.

Trustworthiness is a cornerstone of product reliability, and the 10 32 self-tapping screw excels in this domain. Users often express their confidence in these screws due to their consistent performance. They are widely available, ensuring that replacement and maintenance are straightforward if necessary. Furthermore, detailed product specifications and certifications from recognized bodies provide an additional layer of assurance regarding their quality and safety. For the conscientious professional or enthusiast, selecting the 10 32 self-tapping screw is not merely about securing two pieces of material together, but rather about ensuring that the connection is uncompromised and enduring. Whether for applications requiring frequent disassembly and reassembly or for permanent fixes, these screws have proven their mettle time and again. The guide to utilizing these screws optimally involves understanding both the mechanical properties of the screw and the material to which it is being affixed. Careful attention to aligning screws perpendicular to the surface and applying consistent, appropriate force are critical steps to preventing stripping and ensuring a smooth tapping process. Moreover, using high-quality driver tools enhances the precision and efficiency of installation, confirming a flawless finish. Ultimately, the 10 32 self-tapping screw stands as a reliable tool in the arsenal of fastening solutions. Its ability to provide sturdy, dependable connections across diverse materials and contexts makes it indispensable. By embodying experience, demonstrating expertise, earning recognition, and maintaining trust, these screws offer a blend of functionality, efficiency, and reliability that is unmatched. With their adoption, whether in professional setups or DIY projects, the results invariably meet and often surpass expectations.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News