Affordable Quotes for Self-Drilling Screws with 10% Discount Offer

The Evolution and Importance of Self-Drilling Screws

Self-drilling screws have become an essential component in various construction and manufacturing processes, providing significant advantages over traditional fastening methods. This article explores the characteristics, benefits, and applications of self-drilling screws, with a focus on their growing relevance in the industry as reflected in the 10% growth reported in 2016.

Understanding Self-Drilling Screws

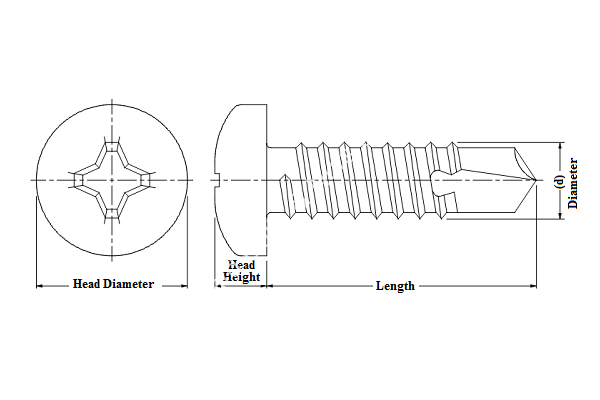

Self-drilling screws are specially designed fasteners equipped with a drill point at their tip. This allows them to create their own hole as they are driven into materials, eliminating the need for pre-drilled pilot holes. They are particularly useful in applications involving metalworking, woodworking, and construction because of their versatility and efficiency.

The different types of self-drilling screws, categorized by their tip shapes and threads, cater to various applications. For instance, screws with a sharp tip are ideal for thin materials, while those with a broader and blunter tip are designed for thicker substrates. The choice of material—whether stainless steel, carbon steel, or coated variations—also adds to their functionality in corrosion resistance and durability.

Advantages of Self-Drilling Screws

The rise in popularity of self-drilling screws can be attributed to several key advantages

1. Efficiency The most notable benefit is time-saving. Since these screws eliminate the need for a separate drilling step, construction teams can significantly reduce installation time. This efficiency translates to cost savings in labor and project timelines.

2. Ease of Use Self-drilling screws are user-friendly, allowing workers, even those with limited experience, to achieve secure fastening without technical complexities. This accessibility leads to quicker training and smoother project execution.

3. Strong Hold The unique design of self-drilling screws enables them to create tight and confident fittings. They offer a strong hold on various materials, including metals, plastics, and wood, making them ideal for both structural applications and aesthetic projects.

10 16 self drilling screw quotes

4. Versatility Self-drilling screws are suitable for a wide range of materials and applications. From roofing and siding to high-load structural connections, their adaptability makes them a go-to option in many industries.

5. Reduced Risk of Damage Traditional drilling can risk damaging materials, particularly when drilling through delicate surfaces. Self-drilling screws mitigate this risk by eliminating the need for a separate hole, ensuring cleaner applications with less chance of material stress.

Market Growth and Trends

The reported 10% growth rate in 2016 also points to a rising demand for self-drilling screws in various sectors, driven by rapid urbanization, ongoing construction projects, and advancements in manufacturing technologies. The construction industry, in particular, has been a significant driver of this growth as buildings are required to meet stringent safety and durability standards.

Moreover, the trend toward prefabrication in construction has increased the demand for efficient fastening solutions. The ability of self-drilling screws to be applied in off-site construction processes simplifies assembly and enhances structural integrity.

Another contributing factor is the push toward sustainable construction practices. The efficiency and reduced waste generated by self-drilling screws align with the goals of green building initiatives, as they lower the amount of energy and resources needed for installations.

Conclusion

As industries seek out effective solutions to enhance productivity and reliability, the significance of self-drilling screws continues to grow. Their inherent advantages—efficiency, strength, ease of use, and versatility—position them as crucial tools in modern construction and manufacturing. The steady market growth indicates a promising future for self-drilling screws, ensuring their place in the ever-evolving landscape of building materials. For anyone involved in construction, manufacturing, or DIY projects, understanding and utilizing self-drilling screws can lead to improved outcomes and streamlined processes.

In summary, self-drilling screws are more than just fasteners; they represent an evolution in how we approach construction and assembly, driving efficiency and performance in an increasingly demanding world. As we plan for future projects, their importance cannot be overlooked, making them a fundamental element of modern engineering and craftsmanship.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024