Jun . 27, 2024 01:37

Back to list

1. Self-Drilling Screw Specs Factory

The Importance of Drilling Screw Specifications in Manufacturing Factories

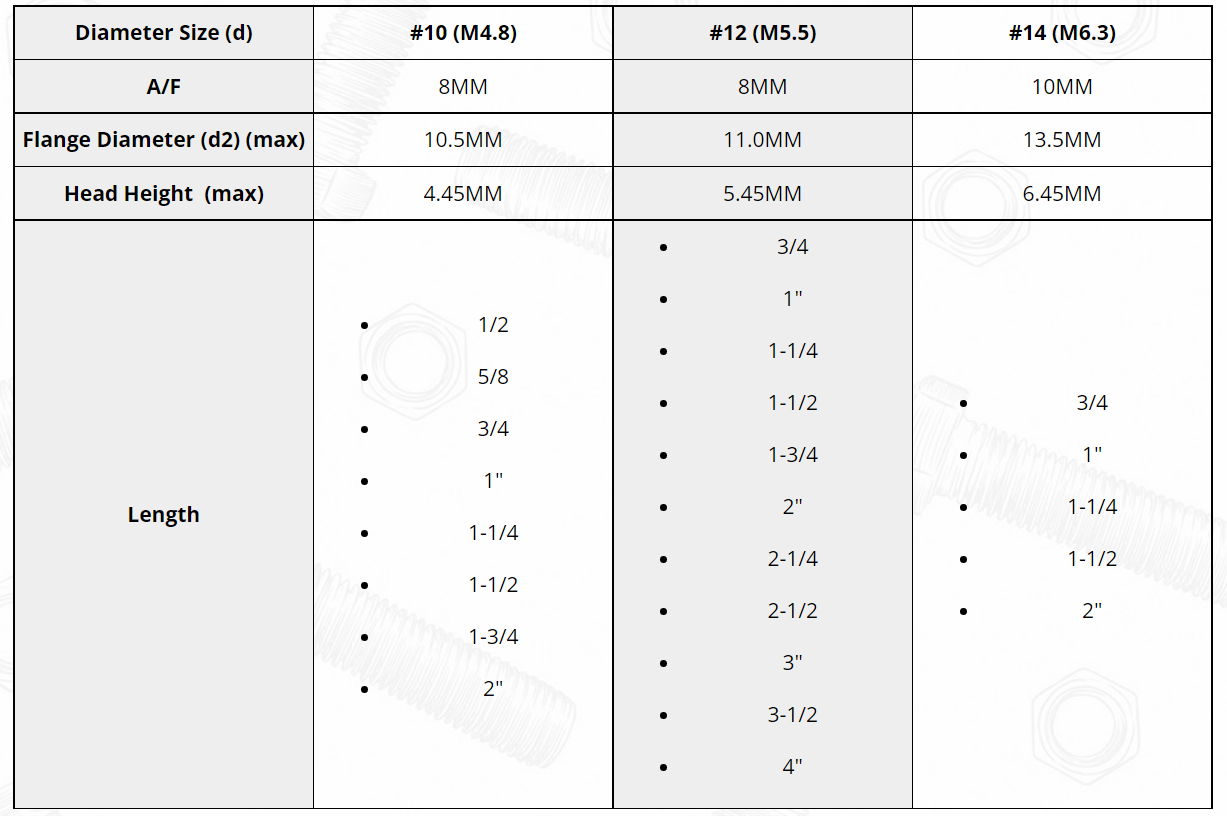

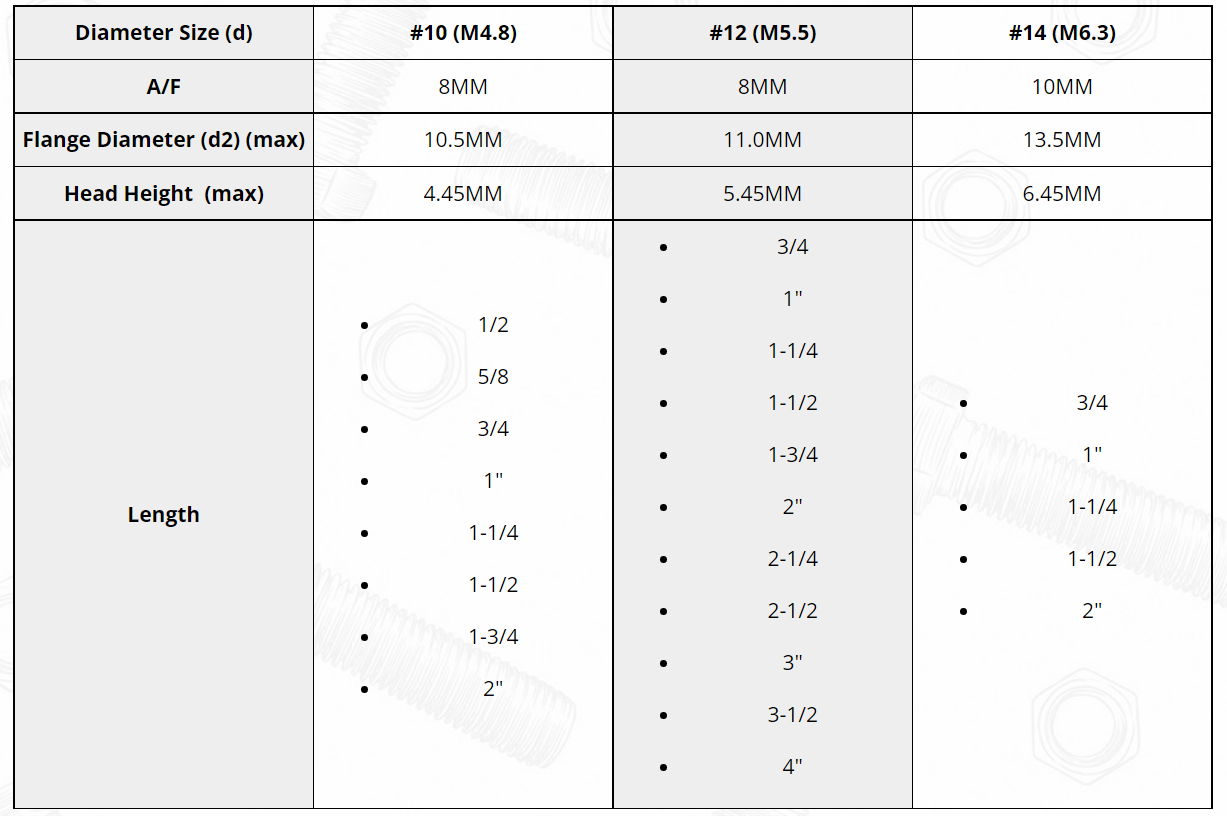

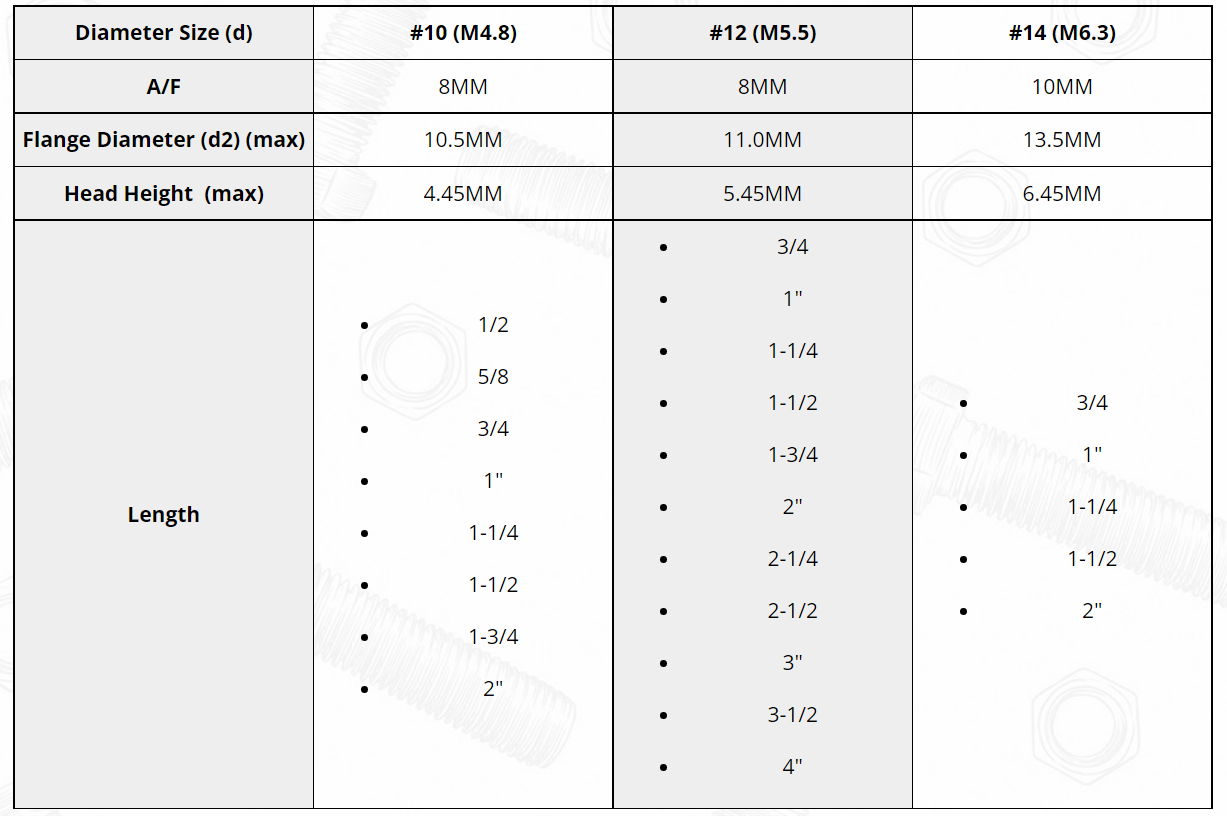

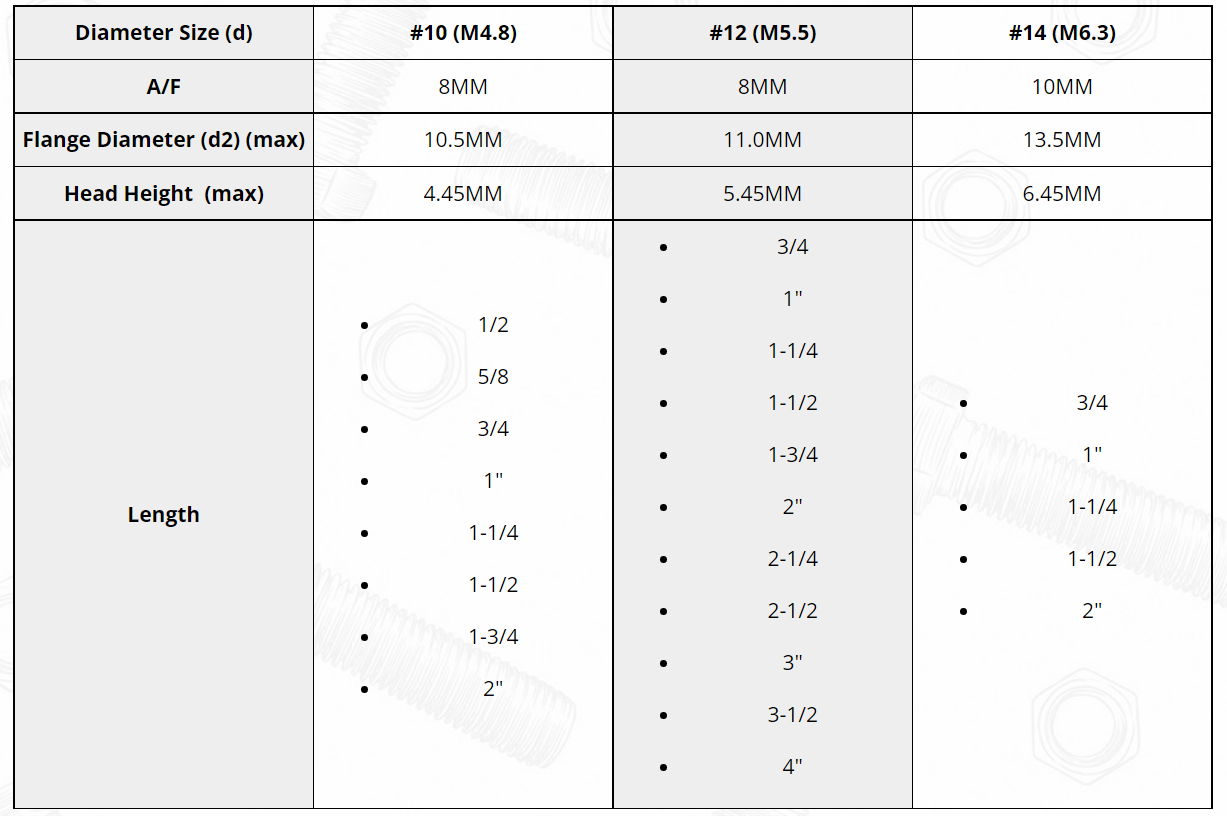

In the manufacturing industry, precision and adherence to specifications are paramount. One such critical aspect is the drilling screw specifications that factories must adhere to for efficient and high-quality production. These specifications encompass various factors, including screw size, thread type, material grade, and coating, among others.

Drilling screws are commonly used in a wide range of applications, from construction to electronics, making it essential for manufacturers to have a thorough understanding of their specifications. For instance, the size of the screw must be appropriate for the intended hole, while the thread type should match the requirements of the material being fastened. Material grade is also crucial, as it determines the strength and durability of the screw.

Furthermore, the coating of the screw plays a significant role in its performance. A good coating can enhance corrosion resistance, improve adhesion, and reduce friction, leading to longer screw life and improved overall performance. Therefore, selecting the right coating based on the specific application is essential Therefore, selecting the right coating based on the specific application is essential Therefore, selecting the right coating based on the specific application is essential Therefore, selecting the right coating based on the specific application is essential

Therefore, selecting the right coating based on the specific application is essential Therefore, selecting the right coating based on the specific application is essential self drilling screw specifications factory.

Adhering to drilling screw specifications is not only important for ensuring product quality but also for maintaining safety standards in the workplace. Improper screw selection or use can lead to accidents, equipment damage, and production delays, resulting in significant financial losses for the factory.

Moreover, meeting drilling screw specifications can help factories streamline their production processes and reduce waste. By using screws that are specifically designed for their application, manufacturers can avoid the need for additional processing steps, such as rework or scrap, thus saving time and resources.

In conclusion, the importance of drilling screw specifications in manufacturing factories cannot be overstated. From ensuring product quality and safety to improving efficiency and reducing waste, these specifications play a vital role in the success of any manufacturing operation. As such, it is crucial for factories to have a comprehensive understanding of their drilling screw requirements and to strictly adhere to them to achieve optimal results.

self drilling screw specifications factory.

Adhering to drilling screw specifications is not only important for ensuring product quality but also for maintaining safety standards in the workplace. Improper screw selection or use can lead to accidents, equipment damage, and production delays, resulting in significant financial losses for the factory.

Moreover, meeting drilling screw specifications can help factories streamline their production processes and reduce waste. By using screws that are specifically designed for their application, manufacturers can avoid the need for additional processing steps, such as rework or scrap, thus saving time and resources.

In conclusion, the importance of drilling screw specifications in manufacturing factories cannot be overstated. From ensuring product quality and safety to improving efficiency and reducing waste, these specifications play a vital role in the success of any manufacturing operation. As such, it is crucial for factories to have a comprehensive understanding of their drilling screw requirements and to strictly adhere to them to achieve optimal results.

Therefore, selecting the right coating based on the specific application is essential Therefore, selecting the right coating based on the specific application is essential

Therefore, selecting the right coating based on the specific application is essential Therefore, selecting the right coating based on the specific application is essential self drilling screw specifications factory.

Adhering to drilling screw specifications is not only important for ensuring product quality but also for maintaining safety standards in the workplace. Improper screw selection or use can lead to accidents, equipment damage, and production delays, resulting in significant financial losses for the factory.

Moreover, meeting drilling screw specifications can help factories streamline their production processes and reduce waste. By using screws that are specifically designed for their application, manufacturers can avoid the need for additional processing steps, such as rework or scrap, thus saving time and resources.

In conclusion, the importance of drilling screw specifications in manufacturing factories cannot be overstated. From ensuring product quality and safety to improving efficiency and reducing waste, these specifications play a vital role in the success of any manufacturing operation. As such, it is crucial for factories to have a comprehensive understanding of their drilling screw requirements and to strictly adhere to them to achieve optimal results.

self drilling screw specifications factory.

Adhering to drilling screw specifications is not only important for ensuring product quality but also for maintaining safety standards in the workplace. Improper screw selection or use can lead to accidents, equipment damage, and production delays, resulting in significant financial losses for the factory.

Moreover, meeting drilling screw specifications can help factories streamline their production processes and reduce waste. By using screws that are specifically designed for their application, manufacturers can avoid the need for additional processing steps, such as rework or scrap, thus saving time and resources.

In conclusion, the importance of drilling screw specifications in manufacturing factories cannot be overstated. From ensuring product quality and safety to improving efficiency and reducing waste, these specifications play a vital role in the success of any manufacturing operation. As such, it is crucial for factories to have a comprehensive understanding of their drilling screw requirements and to strictly adhere to them to achieve optimal results. Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News