Drywall Screw Quality Control in Wholesale Distribution and Inspection Practices

Wholesale Drywall Screw Inspection Ensuring Quality and Reliability

In the construction industry, the integrity of materials used can significantly impact the overall quality and durability of a project. Among these materials, drywall screws play a crucial role in the secure attachment of drywall to framing structures. Therefore, conducting thorough inspections of wholesale drywall screws is essential to ensure that only high-quality screws are used in building projects. This article delves into the importance of drywall screw inspection, the criteria for quality assurance, and the best practices to ensure compliance with industry standards.

Importance of Drywall Screw Inspection

Drywall screws are not just simple fasteners; they are key components that provide structural stability and resilience. Poor-quality screws can lead to various problems, ranging from visible defects to severe structural failures. Inadequately secured drywall not only compromises the aesthetics of the finished project but can also result in costly repairs and maintenance down the line.

Given the large volume of screws that contractors purchase from wholesalers, rigorous inspection processes are imperative to uphold safety and quality standards. A comprehensive inspection can prevent the use of defective screws that might cause drywall to sag, crack, or detach, leading to project delays and increased expenses.

Criteria for Quality Assurance

When inspecting wholesale drywall screws, several crucial criteria need to be evaluated

1. Material Composition High-quality drywall screws are typically made from steel with a corrosion-resistant coating, such as zinc. Inspectors should verify the material composition to ensure that it meets industry standards for strength and durability.

2. Thread Design The thread design impacts how well the screw holds in the drywall and the underlying structure. Inspectors should check for consistent thread patterns that enhance grip and prevent stripping.

3. Point Sharpness The sharpness of the screw point is crucial for ease of installation. Blunt screw points can lead to difficulty in driving screws and increased labor costs. Inspectors should confirm that the points are adequately sharp and designed to penetrate drywall efficiently.

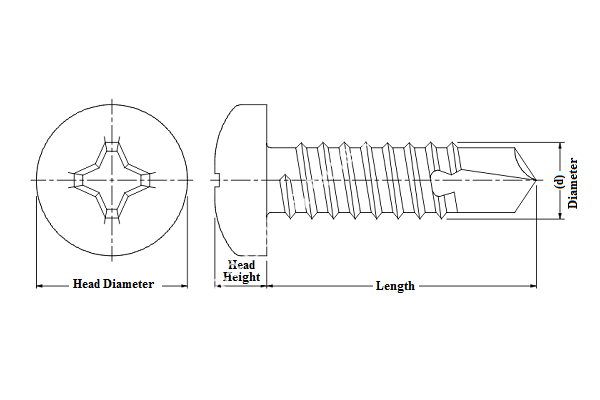

4. Length and Diameter Wholesalers should provide screws in various lengths and diameters to accommodate different installation needs. Inspectors must ensure that the provided sizes match specified requirements and industry norms.

wholesale drywall screw inspection

5. Finish Quality The coating on drywall screws should be uniform, free from rust, and resistant to corrosion. Inspectors need to assess the finish quality to confirm that it meets longevity expectations.

6. Packaging and Labeling Proper packaging helps protect screws from damage during transport and handling. Inspectors should also verify that labeling includes essential information such as batch numbers, specifications, and safety warnings.

Best Practices for Inspection

To ensure the effectiveness of drywall screw inspections, wholesalers and contractors can adopt several best practices

1. Regular Training Providing continuous training for inspection teams can help them stay updated on best practices and industry standards. Well-trained inspectors are more adept at identifying potential defects and ensuring quality.

2. Utilization of Test Methods Employing standardized testing methods can facilitate objective evaluation. This may include tensile strength tests, corrosion resistance tests, and visual inspections for defects.

3. Documentation Maintaining comprehensive inspection records can help track the performance and quality of drywall screws over time. This documentation can be invaluable in identifying patterns in defects and guiding future purchases.

4. Supplier Evaluation Establishing strong relationships with reputable suppliers and manufacturers can enhance the overall quality of drywall screws. Conducting audits and assessments of suppliers ensures that they adhere to set quality standards.

5. Feedback Mechanism Creating a system for receiving feedback from contractors on the performance of drywall screws can provide valuable insights. This feedback can help wholesalers refine their selection and improve future purchases.

Conclusion

Wholesale drywall screw inspection is a critical aspect of ensuring the quality and safety of construction projects. By adhering to stringent inspection criteria and employing best practices, wholesalers can significantly reduce the risk of defects and enhance the reliability of their products. Ultimately, a commitment to quality not only benefits wholesalers but also ensures that builders and contractors can work with confidence, knowing that they are using dependable materials in their projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024