Gen . 14, 2025 09:39

Back to list

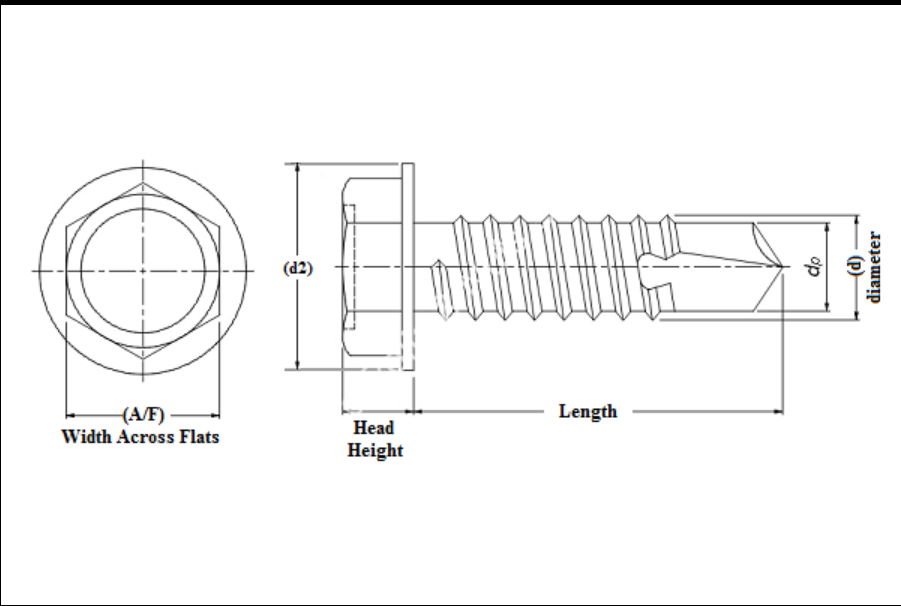

galvanized csk head self drilling screw

Galvanized wafer head self drilling screws have become an indispensable component in modern construction and manufacturing industries, thanks to their unique design and versatile applications. These screws offer a harmonious blend of durability, efficiency, and ease of use, making them a preferred choice for professionals across the globe seeking reliable fastening solutions.

Professionals in the construction and manufacturing sectors appreciate the versatility of galvanized wafer head self drilling screws. From securing metal roofing to assembling furniture, these screws are suitable for a wide range of applications. Their ability to seamlessly integrate into various materials makes them a go-to choice for designers and engineers striving for both function and aesthetics in their projects. In terms of expertise, using galvanized wafer head self drilling screws requires an understanding of material compatibility and load requirements. Professionals should consider factors such as screw length and thread type to ensure optimal performance for specific applications. Moreover, selecting screws with the appropriate galvanization thickness is crucial to match the environmental conditions they will face. Experience tells us that using high-quality screws from reputable manufacturers enhances trustworthiness in construction outcomes. Adhering to manufacturer guidelines and industry standards ensures that the full benefits of these screws are realized, providing a positive impact on both project timelines and longevity. Galvanized wafer head self drilling screws represent a convergence of innovation and practicality. Their design not only simplifies the building process but also assures durability and robust performance. Whether applied in new builds or renovations, their inclusion adds significant value, positioning them as a vital component in modern construction and industrial fabrication projects. As experts in the field continue to pioneer advancements, these screws are poised to remain a cornerstone of efficient and reliable construction methodologies.

Professionals in the construction and manufacturing sectors appreciate the versatility of galvanized wafer head self drilling screws. From securing metal roofing to assembling furniture, these screws are suitable for a wide range of applications. Their ability to seamlessly integrate into various materials makes them a go-to choice for designers and engineers striving for both function and aesthetics in their projects. In terms of expertise, using galvanized wafer head self drilling screws requires an understanding of material compatibility and load requirements. Professionals should consider factors such as screw length and thread type to ensure optimal performance for specific applications. Moreover, selecting screws with the appropriate galvanization thickness is crucial to match the environmental conditions they will face. Experience tells us that using high-quality screws from reputable manufacturers enhances trustworthiness in construction outcomes. Adhering to manufacturer guidelines and industry standards ensures that the full benefits of these screws are realized, providing a positive impact on both project timelines and longevity. Galvanized wafer head self drilling screws represent a convergence of innovation and practicality. Their design not only simplifies the building process but also assures durability and robust performance. Whether applied in new builds or renovations, their inclusion adds significant value, positioning them as a vital component in modern construction and industrial fabrication projects. As experts in the field continue to pioneer advancements, these screws are poised to remain a cornerstone of efficient and reliable construction methodologies.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News