famous self tapping screw diameter

Understanding the Diameter of Famous Self-Tapping Screws

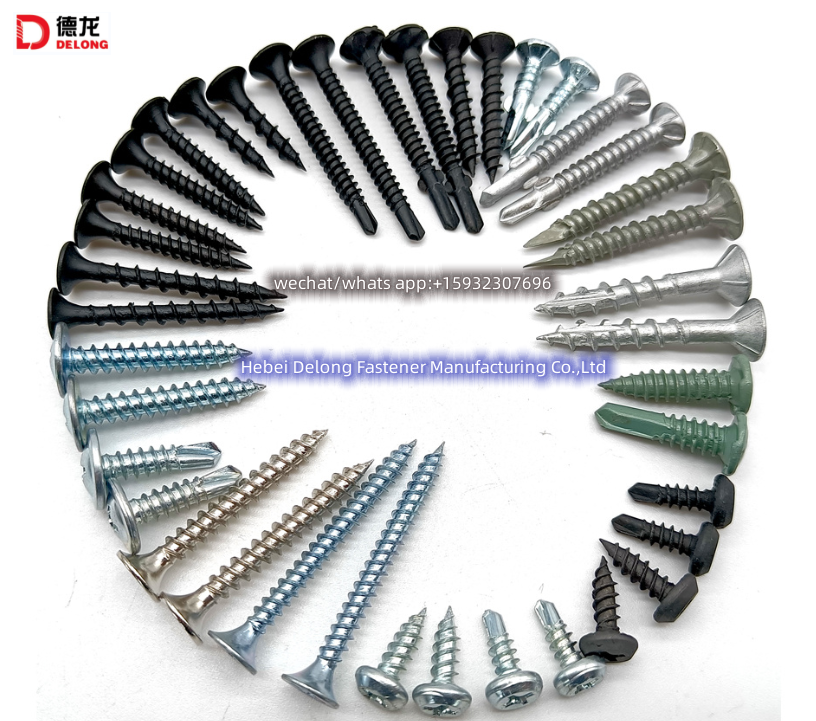

Self-tapping screws are integral components in various industries, from construction to electronics. Their unique design enables them to cut their own threads as they are driven into materials, providing a strong and secure connection without the need for pre-drilled holes. While many factors contribute to the effectiveness of these screws, one crucial aspect is their diameter.

The diameter of a self-tapping screw significantly influences its performance and application. Generally measured in inches or millimeters, the diameter affects the screw's load-bearing capability and the material it can penetrate. For instance, a larger diameter screw can bear more weight and is suitable for thicker materials, making it ideal for heavy-duty applications. On the other hand, smaller diameter screws are often used in delicate tasks where precision is essential, such as in electronics and small assembly projects.

In the realm of self-tapping screws, these diameters can vary widely. Common diameters range from 2 (about 0.086 inches or 2.2 mm) to 14 (about 0.24 inches or 6.1 mm) in imperial measurements, with corresponding metric sizes as well. The choice of diameter depends on various factors, including the type of material being joined, the required strength of the joint, and environmental conditions. For example, stainless steel self-tapping screws, often used in outdoor applications, may come in different diameters based on the corrosive nature of the environment, like coastal regions.

famous self tapping screw diameter

Moreover, the choice of screw diameter also impacts installation ease and speed. Larger screws require more torque and deeper penetration, which may necessitate the use of power tools, while smaller screws can be driven in with manual tools. This consideration is vital in industries where time efficiency is critical.

In addition to practical applications, the diameter of self-tapping screws is also a significant factor in design and engineering. When designing products, engineers must meticulously account for the screw diameter to ensure structural integrity. An improperly sized screw can lead to failures, ultimately compromising the safety of the final product.

It's also worth noting that standards and classifications, such as those set by ANSI (American National Standards Institute) or ISO (International Organization for Standardization), govern the specifications and dimensions of self-tapping screws. Understanding these standards helps manufacturers and engineers choose the correct screw type with the appropriate diameter for their projects.

In conclusion, while self-tapping screws may seem like a simple component, their diameter plays a crucial role in their effectiveness and application. From heavy construction to delicate electronics, the right diameter ensures the reliability and strength of the connection. As industries continue to evolve, the demand for innovation in screw design, including variations in diameter, will likely grow, further highlighting their importance in various fields.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024