standard flat washer sizes service

Understanding Standard Flat Washer Sizes and Their Applications

When it comes to mechanical assemblies, flat washers play a crucial role in ensuring the integrity and reliability of various components. These simple yet effective disks of metal, plastic, or rubber are used primarily to distribute the load of a threaded fastener, such as a bolt or nut. However, their usage is not limited to load distribution; they also serve to protect the surface of the material being fastened and can prevent corrosion between dissimilar materials.

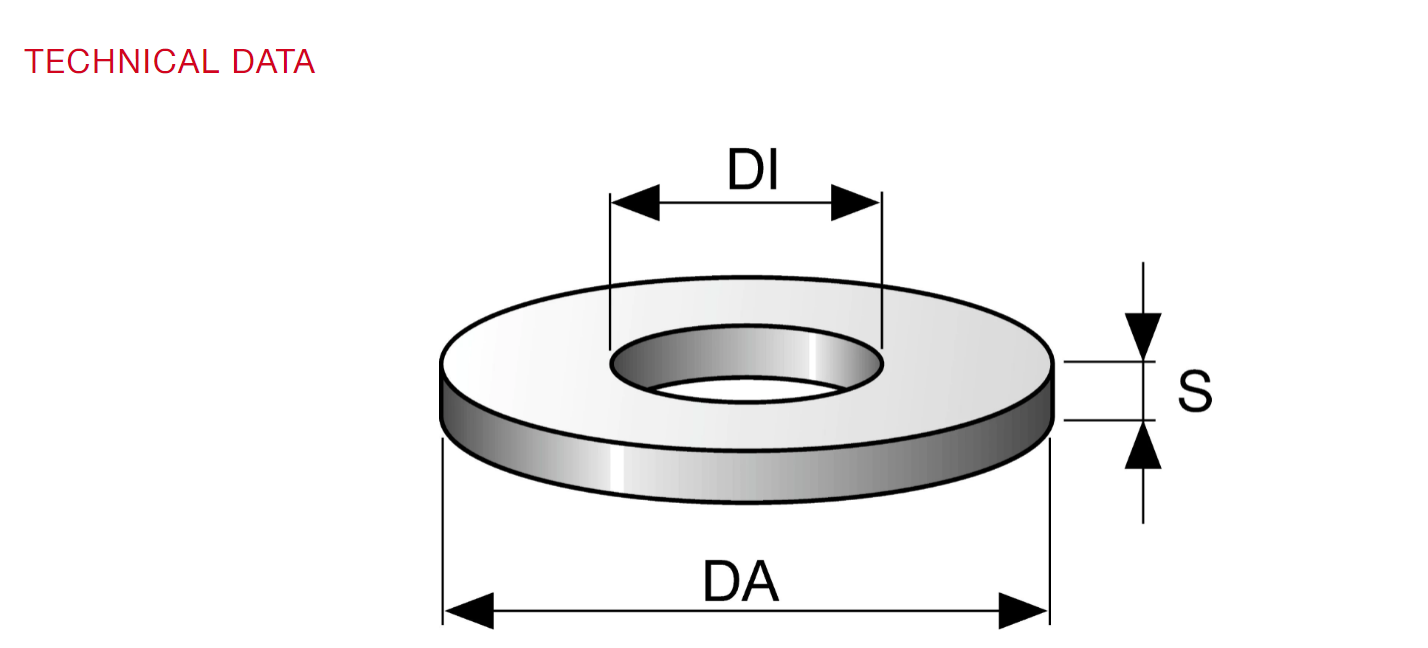

What Are Flat Washers?

Flat washers are circular plates with a hole in the center that are designed to fit over a bolt or screw. The primary purpose is to create a larger surface area for a nut or bolt to attach, helping to prevent it from penetrating the material being fastened. They also help in providing a level surface, thereby increasing the stability of the assembly.

Importance of Standard Sizes

Flat washers come in a variety of sizes, materials, and thicknesses, but adhering to standard sizing is critical for several reasons

1. Interchangeability Standard sizes allow for ease of replacement. When components are designed to meet specific standards, finding the right washer becomes a straightforward task, ensuring that repairs and maintenance can be carried out quickly and efficiently.

2. Compatibility Standard flat washers are designed to fit common bolt and screw sizes, which allows for optimal use across a wide range of industries, from automotive to construction. This eliminates confusion when selecting the right washer for a particular job or project.

3. Cost Efficiency Mass production of standard sizes means lower costs. Manufacturers can produce large quantities of the same size, which reduces production costs and, in turn, lowers the price for consumers.

4. Performance Consistency Standard sizes ensure that washers are designed with specific load-bearing capabilities and material properties in mind. This consistency leads to predictable performance, which is essential for engineers and technicians when designing and constructing machinery and structures.

standard flat washer sizes service

Common Standard Flat Washer Sizes

Flat washers are typically available in both metric and imperial measurements. Here are some commonly used sizes in the metric system

- M5 (5mm bolt diameter) – Washer size approximately 10mm outer diameter - M6 (6mm bolt diameter) – Washer size approximately 12mm outer diameter - M8 (8mm bolt diameter) – Washer size approximately 16mm outer diameter - M10 (10mm bolt diameter) – Washer size approximately 18mm outer diameter - M12 (12mm bolt diameter) – Washer size approximately 24mm outer diameter

In the imperial system, standard sizes include

- 4 (0.112” bolt diameter) – Washer size approximately 0.25” outer diameter - 6 (0.138” bolt diameter) – Washer size approximately 0.312” outer diameter - 8 (0.164” bolt diameter) – Washer size approximately 0.375” outer diameter - 10 (0.190” bolt diameter) – Washer size approximately 0.438” outer diameter - 1/4” (0.250” bolt diameter) – Washer size approximately 0.500” outer diameter

Material Considerations

The effectiveness of a flat washer is influenced not only by its size but also by its material. Common materials include

- Steel Often coated with zinc to resist corrosion, steel washers are durable and ideal for a variety of applications. - Stainless Steel Provides excellent resistance to corrosion and is suitable for outdoor or high-moisture environments. - Plastic Non-conductive and lightweight, plastic washers are often used in electrical applications where conductivity needs to be minimized.

Conclusion

Flat washers may seem like minor components, but they play an essential role in the safety and performance of various mechanical assemblies. Understanding standard flat washer sizes and materials is key for anyone involved in construction, manufacturing, or maintenance. By ensuring the right washer is used, you can significantly improve the longevity and reliability of your assemblies, ultimately saving time and cost in the long run. Always consult the appropriate standards and specifications to make the right choice for your specific application.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024