self tapping screw hole size factory

Understanding Self-Tapping Screw Hole Sizes A Comprehensive Guide

Self-tapping screws are essential components in various construction and manufacturing applications. They are designed to create their own holes as they are driven into materials, facilitating a secure and reliable fastening solution. However, to maximize their effectiveness, it is crucial to understand the proper hole sizes that correspond to these screws.

When selecting a self-tapping screw, one of the most critical factors to consider is the hole size, which directly impacts the screw’s performance and the integrity of the joined materials. Generally, self-tapping screws can be categorized into two main types thread-cutting and thread-forming screws. Each type has its specific requirements for hole size.

Thread-cutting screws, as the name suggests, cut a thread in the material as they are inserted. Therefore, the pilot hole must be slightly smaller than the screw's outer diameter to ensure that the screw can effectively create the threads. The exact size depends on the screw's diameter and the material being fastened. For instance, in softer materials like wood or plastic, a smaller pilot hole may suffice. In contrast, harder materials such as metal may require a more precise hole size to facilitate threading without damaging the material.

self tapping screw hole size factory

On the other hand, thread-forming screws displace material rather than cutting it. These screws are designed for use in pre-drilled holes that match their root diameter. The root diameter is the diameter of the screw without the threads, and it is essential to accommodate the material that will be displaced to maintain the integrity of the fastening. In applications where vibration or movement is a concern, it is crucial that the hole size allows for optimal engagement of the screw threads with the material.

Manufacturers often provide guidelines for the appropriate hole sizes for specific self-tapping screws. It is essential for those involved in construction or manufacturing to familiarize themselves with these guidelines to ensure optimal performance. For instance, a common rule of thumb is to refer to charts that define drill bit sizes suitable for specific screw sizes, taking into account the type of material being used.

In conclusion, understanding the proper hole size for self-tapping screws is vital for achieving secure and long-lasting connections in various applications. By considering the type of screw and material, as well as following manufacturer guidelines, users can ensure that their fastening solutions are effective and reliable. Properly sized holes prevent stripping and damage, leading to stronger constructions and enhanced durability. As industries evolve and demands for efficient fastening solutions increase, the importance of accurately assessing screw hole sizes remains paramount.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

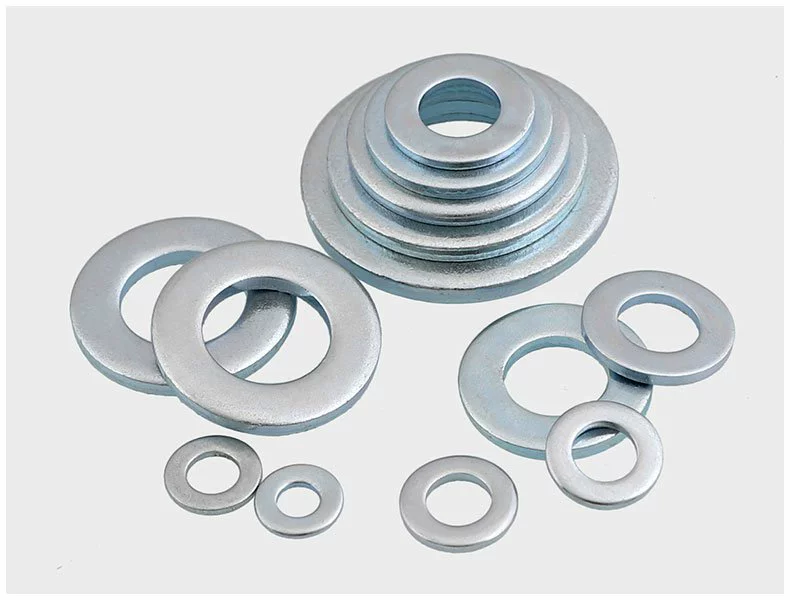

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024