Feb . 04, 2025 05:55

Back to list

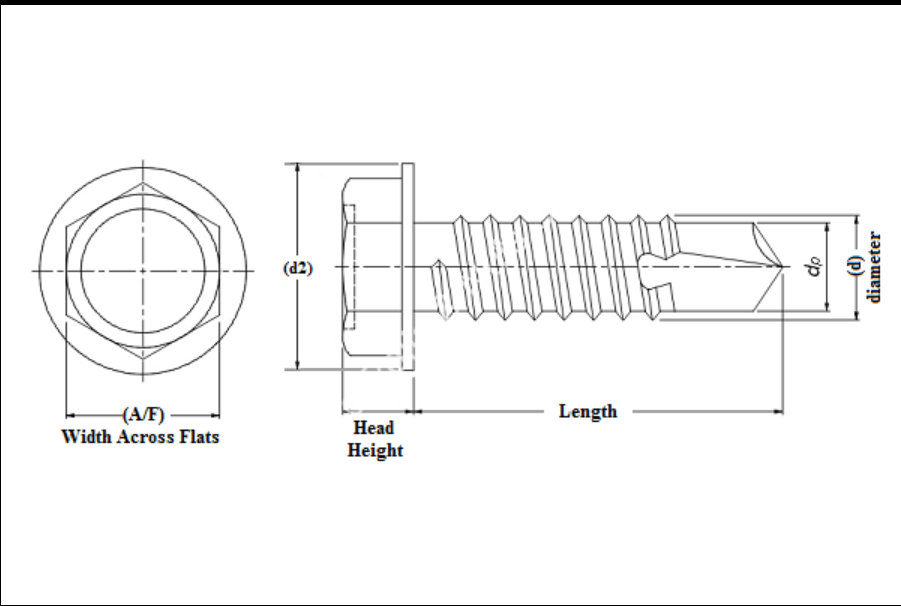

YZP CHIPBOARD SCREW

Self-drilling screwdrivers have revolutionized the way DIY enthusiasts and professionals approach construction, carpentry, and home improvement projects. Their unique capability to drill and fasten in one seamless action has addressed the age-old problem of inefficiency in fastening materials, making them indispensable tools in any toolkit.

One significant advancement in self-drilling screwdriver technology is the integration of smart systems and ergonomic designs. Some models now come equipped with sensors that adjust torque automatically based on the material resistance, enhancing precision and reducing user fatigue. Ergonomically designed handles mitigate strain and provide a firmer grip, allowing for prolonged use without discomfort. Moreover, there has been a concerted effort by manufacturers to increase the sustainability and energy efficiency of self-drilling screwdrivers. Cordless models powered by lithium-ion batteries offer robust power output with extended runtime, eliminating the constraints of corded tools. These batteries are not only long-lasting but are also crafted with sustainability in mind, often being part of recycling programs that reduce environmental impact. The incorporation of digital systems for maintenance and usage tracking is another innovation that boosts the reliability and lifecycle of self-drilling screwdrivers. Manufacturers are now embedding digital interfaces that inform users about tool health, battery status, and even usage analytics. This transparency aids users in maintaining their tools better, ensuring peak performance and longevity. Selecting the right self-drilling screwdriver involves understanding the specific needs of the project and matching them with the tool's capabilities. Assessing factors like the screwdriver’s power source, bit compatibility, weight, and ergonomic features can be pivotal in achieving optimal results. It's crucial to also consider trusted brands that offer comprehensive warranties and customer support, confirming the tool’s reliability and the company's confidence in their product quality. For many users, investing in a self-drilling screwdriver is a decision that pays dividends in efficiency, precision, and durability. Recognized for their expert craftsmanship and reliable performance, these tools have garnered a reputation for excellence within the DIY and professional communities. Users can trust them to deliver repeated excellence across various projects, making them a wise addition to any tool arsenal. With ongoing innovations and improvements, self-drilling screwdrivers continue to assert their rightful place at the forefront of efficient fastening technology.

One significant advancement in self-drilling screwdriver technology is the integration of smart systems and ergonomic designs. Some models now come equipped with sensors that adjust torque automatically based on the material resistance, enhancing precision and reducing user fatigue. Ergonomically designed handles mitigate strain and provide a firmer grip, allowing for prolonged use without discomfort. Moreover, there has been a concerted effort by manufacturers to increase the sustainability and energy efficiency of self-drilling screwdrivers. Cordless models powered by lithium-ion batteries offer robust power output with extended runtime, eliminating the constraints of corded tools. These batteries are not only long-lasting but are also crafted with sustainability in mind, often being part of recycling programs that reduce environmental impact. The incorporation of digital systems for maintenance and usage tracking is another innovation that boosts the reliability and lifecycle of self-drilling screwdrivers. Manufacturers are now embedding digital interfaces that inform users about tool health, battery status, and even usage analytics. This transparency aids users in maintaining their tools better, ensuring peak performance and longevity. Selecting the right self-drilling screwdriver involves understanding the specific needs of the project and matching them with the tool's capabilities. Assessing factors like the screwdriver’s power source, bit compatibility, weight, and ergonomic features can be pivotal in achieving optimal results. It's crucial to also consider trusted brands that offer comprehensive warranties and customer support, confirming the tool’s reliability and the company's confidence in their product quality. For many users, investing in a self-drilling screwdriver is a decision that pays dividends in efficiency, precision, and durability. Recognized for their expert craftsmanship and reliable performance, these tools have garnered a reputation for excellence within the DIY and professional communities. Users can trust them to deliver repeated excellence across various projects, making them a wise addition to any tool arsenal. With ongoing innovations and improvements, self-drilling screwdrivers continue to assert their rightful place at the forefront of efficient fastening technology.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News