Machine Screws vs Self-Tapping Screws

Machine Screws vs. Self-Tapping Screws Understanding the Differences and Applications

When it comes to fastening components in various engineering and construction projects, two prevalent options are machine screws and self-tapping screws. While these fasteners may seem similar at first glance, they serve distinct purposes and are designed for different applications. Understanding the differences between machine screws and self-tapping screws is essential for selecting the right type for your project.

Definition and Construction

A machine screw is a type of fastener characterized by a uniform diameter along its entire length, featuring a head at one end and often requiring a nut or a tapped hole for fastening

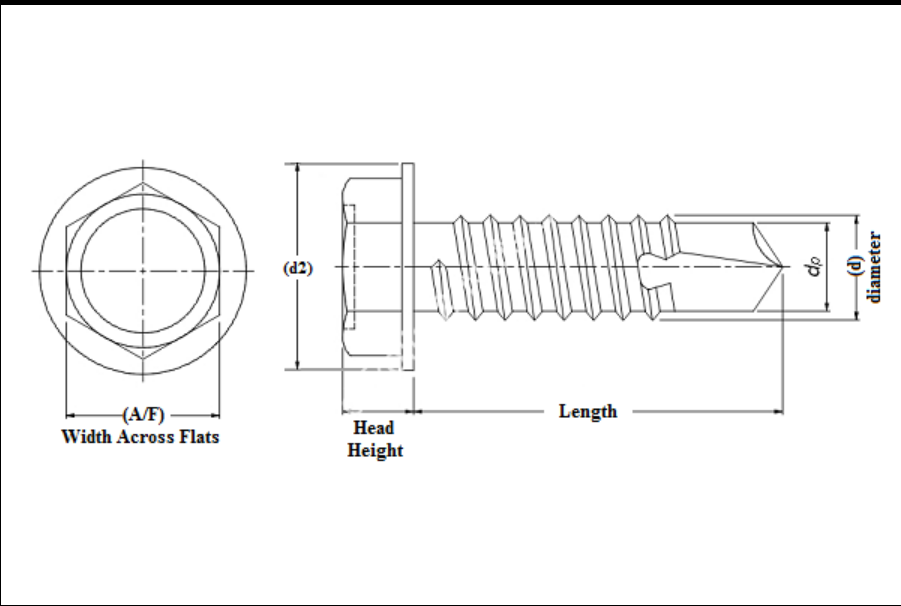

. Typically made of materials such as steel, stainless steel, or brass, machine screws come with various head styles and thread configurations, making them suitable for a wide range of applications in mechanical and structural assemblies.In contrast, self-tapping screws are designed to create their own thread as they are driven into materials. They possess sharp threads that allow them to drill into plastic, metal, and wood without the need for a pre-drilled hole. This feature can streamline the assembly process and make self-tapping screws a convenient choice for projects where quick fastening is crucial.

Installation Process

The installation procedures for machine screws and self-tapping screws vary significantly. Machine screws generally require precise pre-drilling and tapping to ensure that the screw can fit securely within the designated hole. For tight tolerances and load-bearing applications, machine screws are often paired with nuts or washers to distribute force and enhance grip.

machine screw vs self tapping factories

On the other hand, self-tapping screws allow for a more straightforward installation process. With their ability to form threads in the substrate material itself, these screws can easily be screwed directly into place with a power drill or screwdriver. This simplicity makes them a favored choice for some home improvement projects and rapid assembly situations.

Applications and Usage

Machine screws are commonly utilized in applications requiring a strong and reliable fastening, such as in machinery, automotive industries, electronics, and structural frameworks. Their ability to endure high loads makes them suitable for critical applications where safety and durability are paramount.

Self-tapping screws, meanwhile, are frequently used in construction and DIY projects, where speed and efficiency are essential. They are ideal for applications involving metal sheets, wood, plastic, and thin materials, making them versatile for various home and industrial tasks.

Conclusion

In summary, while both machine screws and self-tapping screws are vital fasteners in the engineering and construction realms, they are tailored for different purposes. Machine screws are best suited for applications requiring precision and durability, while self-tapping screws excel in situations demanding quick assembly. Understanding the unique characteristics and applications of each can help ensure that the right fastener is chosen, leading to successful project outcomes. Whether you are a seasoned engineer or a DIY enthusiast, selecting the appropriate screw can make all the difference in the performance and quality of your work.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024