Durable 6mm Flat Washer for Reliable Performance and Versatile Applications

The Importance of High-Quality 6mm Flat Washers in Various Applications

Flat washers are often an overlooked component in mechanical design and construction, yet they play a crucial role in ensuring durability, stability, and performance in various applications. Among these, the 6mm flat washer stands out as one of the most commonly used types in both industrial and domestic projects. Understanding the significance of high-quality 6mm flat washers can help engineers, manufacturers, and DIY enthusiasts make informed decisions to enhance the reliability of their assemblies.

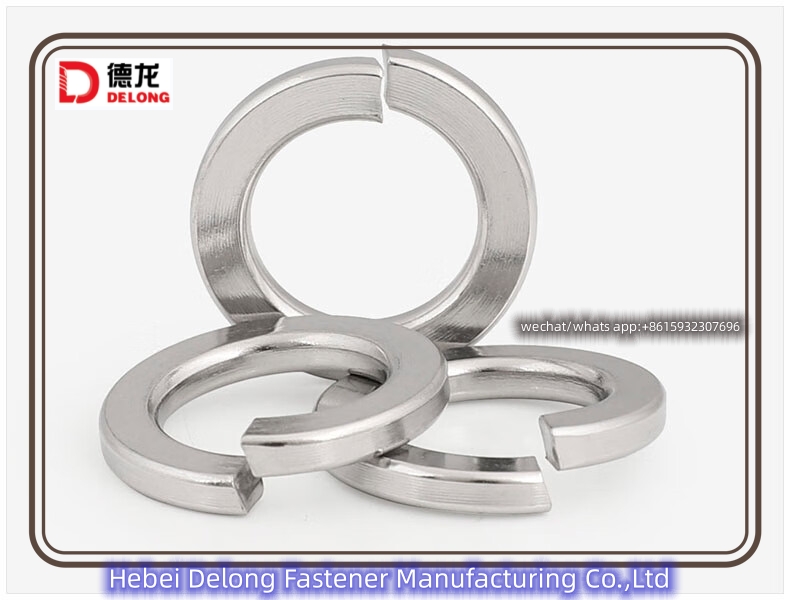

What is a Flat Washer?

A flat washer is a thin, disc-shaped piece of metal or plastic with a hole in the center. It is placed between a fastener, such as a nut or bolt, and the surface being fastened. The primary functions of a flat washer are to distribute the load of the fastener and reduce the likelihood of damage to the surface it contacts. They also help in preventing loosening due to vibration and fatigue over time.

Why Choose High-Quality 6mm Flat Washers?

1. Material Quality High-quality flat washers are typically made from superior materials such as stainless steel, carbon steel, or specific alloys that provide enhanced strength and resistance to corrosion. For applications exposed to moisture or harsh environments, stainless steel washers are ideal as they protect against oxidation and rust.

2. Load Distribution The primary role of a washer is to distribute the load across a larger surface area. High-quality 6mm flat washers ensure that this distribution is effective, preventing stress concentrations that can lead to material failure. This is particularly critical in heavy machinery or structural applications where the integrity of components is paramount.

3. Vibration Resistance In many applications, particularly in automotive and aerospace sectors, vibration is a significant concern. High-quality washers help in dampening vibrations and preventing loosening of fasteners over time, which can result in costly repairs or catastrophic failures.

high quality 6mm flat washer

4. Precision Engineering A well-manufactured 6mm flat washer adheres to strict dimensional tolerances. This precision ensures proper fit and performance, minimizing the risks associated with poorly fitted components that can compromise the overall assembly.

5. Versatility High-quality flat washers are versatile and can cater to a wide range of applications, from low-stress domestic jobs, like assembling furniture, to high-stress industrial tasks such as constructing heavy machinery or infrastructure projects. Their reliability makes them a staple in various industries, including automotive, aerospace, and construction.

Selecting the Right 6mm Flat Washer

When selecting the right flat washer, consider the following factors

- Material Compatibility Ensure that the washer material is compatible with other materials in the assembly to prevent galvanic corrosion. - Load Requirements Identify the load-bearing capacity required for your application to choose the appropriate washer type and thickness. - Environmental Factors Consider the environment in which the washer will be used. For indoor applications, standard steel may suffice, but for outdoor or corrosive environments, stainless steel or specialized coatings are preferable.

Conclusion

In conclusion, high-quality 6mm flat washers are an essential component in a wide range of applications, offering benefits such as effective load distribution, resistance to vibration, and enhanced durability. By investing in quality washers, engineers and builders can improve the reliability and longevity of their projects. Whether you are working on a large scale industrial project or a simple DIY task, recognizing the significance of these small yet mighty components can make a substantial difference in the overall success of your endeavors. Choose wisely, and ensure a sturdy, long-lasting assembly with high-quality flat washers.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024