Exploring the Benefits of Custom Chipboard Screws for Your Projects

Understanding Custom Chipboard Screws A Comprehensive Guide

When it comes to woodworking and furniture assembly, the type of fasteners used is just as crucial as the materials themselves. Among the various types of screws available, custom chipboard screws have emerged as a popular choice due to their versatility and specialized design. This article will delve into what custom chipboard screws are, their unique features, applications, and the factors to consider when selecting the right screw for your project.

What are Custom Chipboard Screws?

Custom chipboard screws are specifically designed for fastening chipboard, MDF (medium-density fiberboard), and other particle board materials commonly used in furniture production and cabinetry. Unlike standard wood screws, chipboard screws have a unique thread design that allows them to grip the material securely without splitting it. This makes them ideal for constructing flat-pack furniture, cabinet assemblies, and other projects where particle board is the primary material.

Unique Features of Custom Chipboard Screws

1. Thread Design Chipboard screws typically feature deep, coarse threads that enable them to bite into the soft material without causing damage. This thread design allows for a strong grip, ensuring that the joints remain tight over time and under load.

2. Self-Cutting Tips Many custom chipboard screws come equipped with self-countersinking tips that eliminate the need for pre-drilling. This saves time during assembly and reduces the risk of splitting the chipboard, making the assembly process more efficient.

3. Material Specifications Quality custom chipboard screws are often made from high-strength steel and may come with various finishes, such as zinc plating, to enhance corrosion resistance. This is particularly important when the screws are used in environments subject to humidity or moisture.

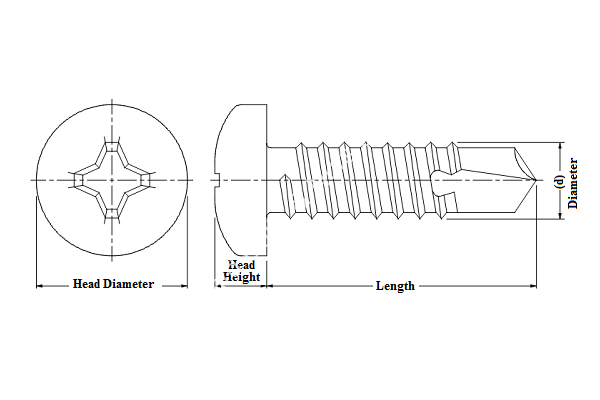

4. Length and Diameter Options Custom screws can be produced in various lengths and diameters to accommodate different thicknesses of chipboard. This customization is essential for achieving optimal performance based on the specific application.

Applications of Custom Chipboard Screws

1. Flat-Pack Furniture The rise of flat-pack furniture has led to increased demand for chipboard screws. They are used extensively in assembling ready-to-assemble (RTA) furniture, ensuring sturdy and reliable connections.

custom chipboard screw

2. Cabinetry In kitchen and bathroom cabinetry, custom chipboard screws are used to secure cabinet doors, shelves, and hardware fittings. Their strength and reliability are crucial for maintaining the integrity of the cabinetry over time.

3. Paneling and Wall Systems Modern interior design often incorporates chipboard for wall paneling and modular systems. Custom screws help attach these panels securely, providing a clean and professional finish.

4. DIY Projects For hobbyists and DIY enthusiasts, custom chipboard screws are a go-to choice for projects involving particle board or MDF, thanks to their ease of use and effective fastening capabilities.

Selecting the Right Custom Chipboard Screw

When choosing the right custom chipboard screw for your project, consider the following factors

1. Material Compatibility Ensure the screw is appropriate for the type of chipboard or MDF you are using. Different densities may require different screw specifications.

2. Screw Length Select a screw length that will adequately penetrate the material without risking breakout or cracking. A good rule of thumb is to use screws that are at least 1.5 times the thickness of the board being joined.

3. Coating and Finish Consider the environment in which the furniture or paneling will be located. Choose corrosion-resistant coatings for humid or damp areas to prevent rust and degradation over time.

4. Cost and Availability Customization can vary in price depending on the specifications. It’s advisable to shop around and compare prices, keeping in mind the importance of quality and durability.

Conclusion

Custom chipboard screws are essential for anyone working with particle board, MDF, or similar materials. Their unique features and specialized design make them superior for furniture assembly and various construction applications. By understanding their functions and selecting the right screws for your projects, you can ensure strong, durable, and visually appealing results that last. Whether you are a professional carpenter or an enthusiastic DIYer, investing in high-quality custom chipboard screws will significantly enhance the efficiency and quality of your work.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024