best self tapping screw standard

Understanding the Best Self-Tapping Screw Standards

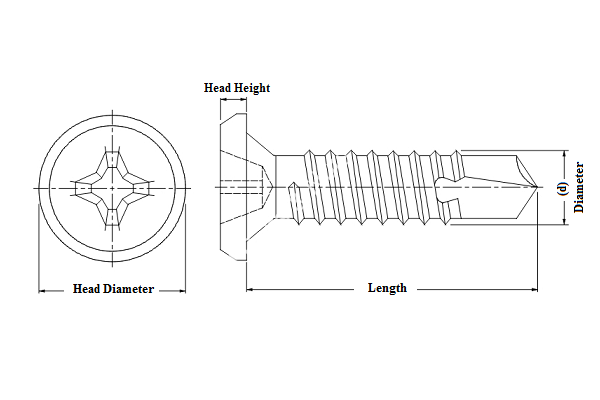

Self-tapping screws are essential fasteners in various industries, offering a reliable means of joining materials without the need for pre-drilled holes. Their unique design allows them to create their own threads as they are driven into a material, making them a popular choice for applications in construction, automotive, and electronics. However, the effectiveness of self-tapping screws is largely determined by the adherence to specific standards. This article explores the importance of best self-tapping screw standards and their impact on performance and safety.

What are Self-Tapping Screws?

Self-tapping screws are distinguished by their ability to tap their own holes as they are driven into the substrate. They are commonly made from materials such as steel, stainless steel, or brass and come in various sizes and designs for different applications. The key characteristic of these screws is the thread design, which allows them to cut into the material, providing a strong hold. The two primary types of self-tapping screws are the thread-forming screws and thread-cutting screws, each designed for specific material applications.

Importance of Standards

Standards are crucial for self-tapping screws as they ensure consistency, quality, and safety across different manufacturers and applications. Organizations such as the American National Standards Institute (ANSI), the International Organization for Standardization (ISO), and the American Society for Testing and Materials (ASTM) have established guidelines that govern the specifications of self-tapping screws. These standards address critical aspects, including dimensions, material properties, mechanical performance, and testing methods.

By adhering to these standards, manufacturers can produce self-tapping screws that meet the necessary strength and durability requirements for various applications. For instance, the tensile strength and corrosion resistance of screws are crucial for their performance in harsh environments, such as marine or industrial settings. Without standardization, there is a risk of using subpar screws that could lead to failures in critical assemblies, resulting in costly repairs and potential safety hazards.

best self tapping screw standard

Key Standards for Self-Tapping Screws

There are several key standards that manufacturers should follow when producing self-tapping screws

1. ISO 1478 This standard provides guidelines on the test methods for determining the ultimate tensile strength and yield strength of self-tapping screws, ensuring they can withstand required loads without failure.

2. ASTM F1413 This specification outlines the requirements for the design and performance of self-tapping screws used in metal-to-metal applications, emphasizing their ability to maintain integrity under load.

3. ANSI/ASME B18.6.1 This standard defines the dimensional and physical properties of various types of screws, including self-tapping variants, ensuring compatibility across different products and manufacturers.

Conclusion

The best self-tapping screw standards are pivotal in ensuring that these fasteners perform effectively and safely in their intended applications. By following established guidelines, manufacturers can produce high-quality screws that provide strong fastening solutions while minimizing the risk of failures. For consumers, understanding these standards can also guide them in selecting the right fasteners for their projects, ensuring reliability and safety in their constructions. As industries continue to evolve and demand better performance from their components, adherence to self-tapping screw standards will remain an essential aspect of manufacturing and engineering practices.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024