Jan . 19, 2025 01:48

Back to list

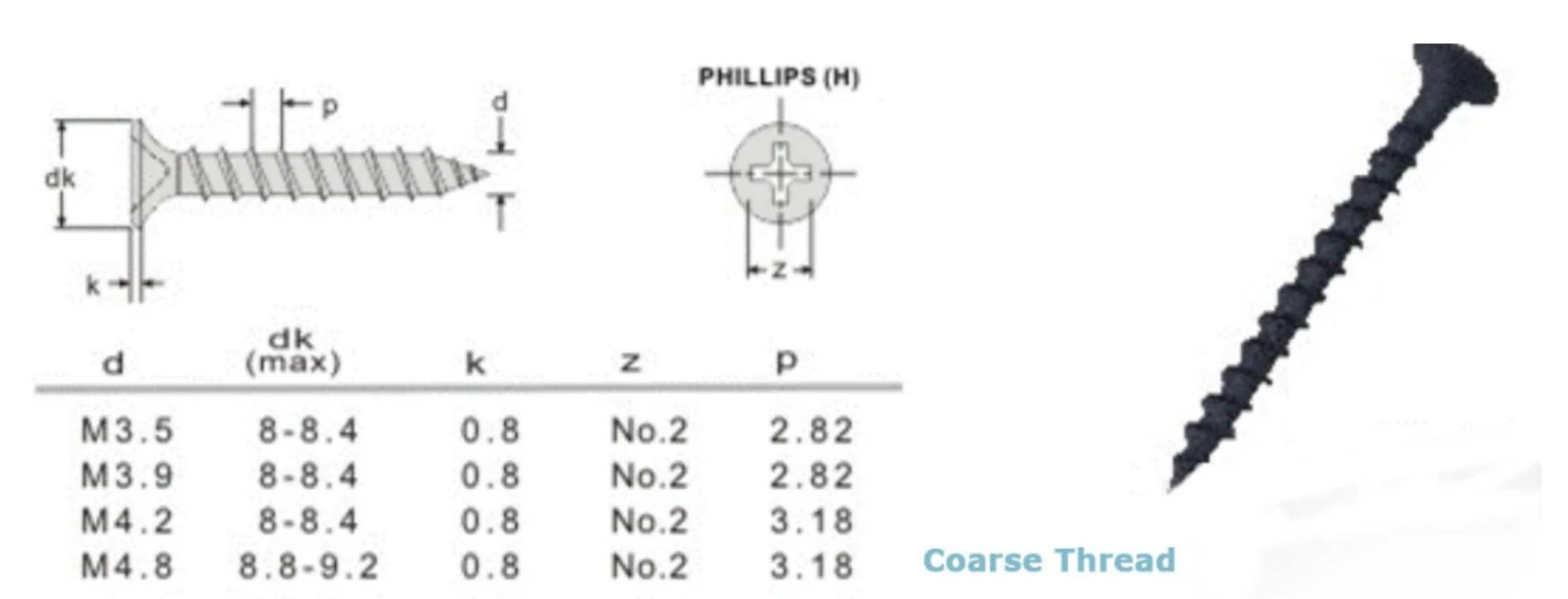

4 self tapping screw

When it comes to achieving high-quality construction and DIY projects, the selection of fasteners is crucial. While there are many types of screws available, self-tapping screws stand out for their versatile applications and robust performance. Understanding the importance of the 4 self-tapping screw can greatly enhance the efficiency and durability of your projects.

The authority of using self-tapping screws, particularly the number 4, emanates from years of industry validation. Builders, engineers, and manufacturers place their trust in these screws because they meet stringent quality and performance standards. This long-standing trust is a testament to their design and functional superiority over other fasteners. For an enhanced trustworthiness in any project, it is advisable to opt for screws that are made from high-quality materials like stainless steel or carbon steel with a suitable coating for corrosion resistance. When the environment's impact is a concern, these materials ensure that the screws will not deteriorate, which could compromise the structural integrity over time. Moreover, using the correct installation techniques is paramount for realizing the full benefits of the 4 self-tapping screw. This includes choosing the appropriate screwdriver bit to match the screw head, thereby preventing stripping and ensuring a firm drive. Proper alignment during installation also optimizes the screw's holding power, a crucial factor for achieving long-lasting joints. In conclusion, the value of the 4 self-tapping screw in both residential and industrial projects cannot be overstated. Their efficacy across a range of materials, coupled with their ease of use and robust hold, make them an indispensable component in the toolkit of any builder. As an authoritative choice in the fastener industry, these screws promise not only efficiency and convenience but also reliability and longevity, making them a favored option for high-quality construction outcomes.

The authority of using self-tapping screws, particularly the number 4, emanates from years of industry validation. Builders, engineers, and manufacturers place their trust in these screws because they meet stringent quality and performance standards. This long-standing trust is a testament to their design and functional superiority over other fasteners. For an enhanced trustworthiness in any project, it is advisable to opt for screws that are made from high-quality materials like stainless steel or carbon steel with a suitable coating for corrosion resistance. When the environment's impact is a concern, these materials ensure that the screws will not deteriorate, which could compromise the structural integrity over time. Moreover, using the correct installation techniques is paramount for realizing the full benefits of the 4 self-tapping screw. This includes choosing the appropriate screwdriver bit to match the screw head, thereby preventing stripping and ensuring a firm drive. Proper alignment during installation also optimizes the screw's holding power, a crucial factor for achieving long-lasting joints. In conclusion, the value of the 4 self-tapping screw in both residential and industrial projects cannot be overstated. Their efficacy across a range of materials, coupled with their ease of use and robust hold, make them an indispensable component in the toolkit of any builder. As an authoritative choice in the fastener industry, these screws promise not only efficiency and convenience but also reliability and longevity, making them a favored option for high-quality construction outcomes.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News