wholesale m2x10 self tapping screw for plastics

The Versatility and Benefits of Wholesale Self-Tapping Screws for Plastics

When it comes to construction and manufacturing, self-tapping screws play a crucial role in ensuring the stability and durability of various materials, particularly plastics. As industries evolve, the demand for efficient fastening solutions has led to the increased use of wholesale self-tapping screws. These screws are designed to create their own thread when driven into a material, making them an ideal choice for applications involving plastic components. This article explores the features, advantages, and considerations of using self-tapping screws specifically for plastics.

Understanding Self-Tapping Screws

Self-tapping screws are unique fasteners that can tap their own hole as they are driven into materials. This ability makes them particularly useful in plastic applications, where the need for precision and ease of installation is paramount. The design of self-tapping screws typically includes a sharp tip that enables penetration without the need for pre-drilling, making them efficient and time-saving.

Why Use Self-Tapping Screws for Plastics?

Plastics are widely used in various industries due to their lightweight, corrosion-resistant, and versatile nature. However, fastening plastics can be a challenge because traditional screws may not grip effectively or can cause cracking and splitting. Self-tapping screws offer several advantages in this context

1. Ease of Installation With their ability to tap threads on their own, self-tapping screws eliminate the need for additional processes like drilling pilot holes. This saves time and labor, which is especially beneficial in high-volume production environments.

2. Reduced Risk of Damage Plastics can be prone to damage if too much force is applied or if incorrect installation techniques are used. Self-tapping screws provide a controlled method of fastening, minimizing the risk of stripping or cracking the material.

3. Versatile Applications These screws can be used in a variety of plastic materials, including but not limited to acrylic, nylon, and polycarbonate. Their adaptability makes them a popular choice for automotive, electronics, and consumer goods industries.

4. Strength and Stability Self-tapping screws create a strong mechanical bond by forming their own threads in the plastic. This leads to a secure fit that can withstand vibration, thermal expansion, and other stresses that might compromise traditional fasteners.

wholesale m2x10 self tapping screw for plastics

5. Cost-Effectiveness Purchasing self-tapping screws wholesale allows manufacturers and contractors to reduce costs significantly. Buying in bulk often leads to lower prices per unit, enabling businesses to maximize their resources while ensuring quality fasteners.

Considerations When Choosing Self-Tapping Screws

While the benefits of self-tapping screws for plastics are clear, several factors should be taken into account when selecting the appropriate fastener for a specific application

1. Material Compatibility Not all self-tapping screws are made equal; the material of the screw itself must be compatible with the type of plastic being used. For example, stainless steel screws may be preferred in environments where corrosion is a concern, while coated screws may be better suited for aesthetic applications.

2. Size and Thread Design The dimensions and thread design of the screw must match the requirements of the project. It’s essential to consider factors such as the thickness of the plastic, the load it will bear, and the expected environmental conditions.

3. Installation Method While self-tapping screws are designed for easy installation, the method used (manual or power tools) can affect the outcome. Understanding the torque settings and speed is important for achieving optimal results and avoiding damage.

4. Quality Control When sourcing self-tapping screws wholesale, it's vital to prioritize quality. Scrutinizing suppliers for certifications and product standards can ensure that the screws perform reliably in their intended applications.

Conclusion

In conclusion, wholesale self-tapping screws for plastics are an essential component for many industries, providing a blend of ease of use, efficiency, and strong fastening capabilities. By understanding the advantages they bring and considering key factors when selecting these screws, manufacturers and contractors can make informed decisions that enhance their projects' overall quality and performance. As industries continue to innovate and adopt new materials, self-tapping screws will undoubtedly remain a staple in the toolkit of professionals worldwide.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

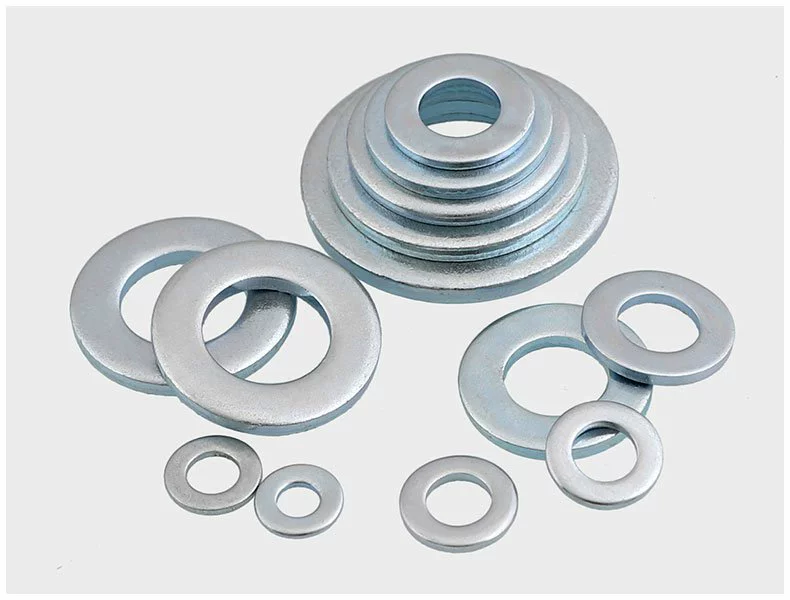

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024