velj . 18, 2025 12:17

Back to list

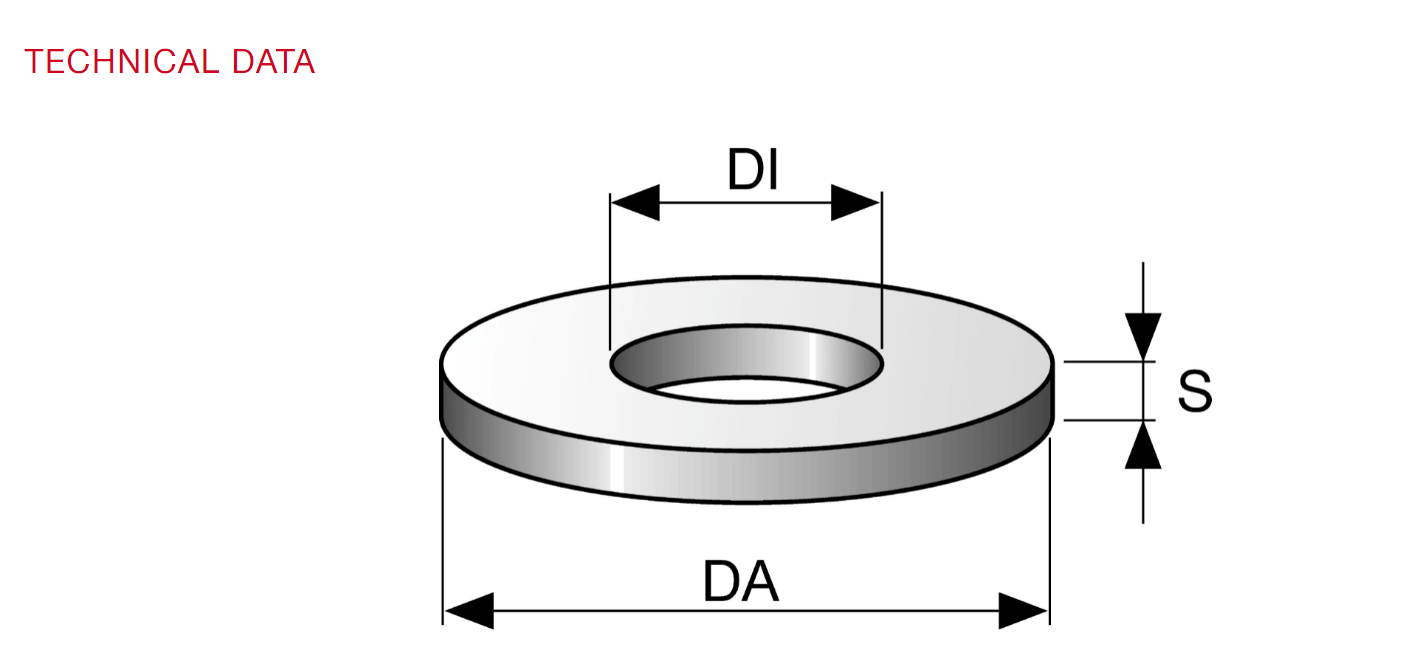

FLAT WASHER

In the realm of construction and machinery, the unassuming B flat washer plays a crucial role that often goes unnoticed. These small, circular plates are indispensable in various assemblies, providing a flat bearing surface that distributes loads, prevents wear, and ensures the integrity of joints. Their application extends from heavy-duty industrial machinery to household furniture, underscoring their versatility and importance.

In terms of authoritativeness, B flat washers are governed by various standards and regulations set by organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). Compliance with these standards ensures that the washers meet the necessary specifications for hardness, dimensions, and finish. This adherence not only guarantees quality but also promotes trustworthiness among consumers and professionals who depend on these components for critical applications. The B flat washer embodies both simplicity and complexity, a testament to its engineering evolution over decades. Historically, washers were handmade, but today’s precision manufacturing processes ensure uniformity and precision down to the smallest detail. This evolution underscores the importance of continual innovation in maintaining the relevance and efficacy of even the most basic components. For those looking to purchase B flat washers, understanding these facets can significantly influence the decision-making process. Suppliers with a robust track record, demonstrated expertise, and adherence to industry standards are preferred, as they ensure that the products supplied are reliable and suitable for their intended applications. In conclusion, the B flat washer is a vital component that underpins the functionality and safety of countless assemblies. Its role, though simple, demands an understanding of material science, engineering principles, and industry standards. As the silent guardian of structural integrity, the B flat washer upholds the tenets of Experience, Expertise, Authoritativeness, and Trustworthiness, providing peace of mind to engineers and consumers alike.

In terms of authoritativeness, B flat washers are governed by various standards and regulations set by organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). Compliance with these standards ensures that the washers meet the necessary specifications for hardness, dimensions, and finish. This adherence not only guarantees quality but also promotes trustworthiness among consumers and professionals who depend on these components for critical applications. The B flat washer embodies both simplicity and complexity, a testament to its engineering evolution over decades. Historically, washers were handmade, but today’s precision manufacturing processes ensure uniformity and precision down to the smallest detail. This evolution underscores the importance of continual innovation in maintaining the relevance and efficacy of even the most basic components. For those looking to purchase B flat washers, understanding these facets can significantly influence the decision-making process. Suppliers with a robust track record, demonstrated expertise, and adherence to industry standards are preferred, as they ensure that the products supplied are reliable and suitable for their intended applications. In conclusion, the B flat washer is a vital component that underpins the functionality and safety of countless assemblies. Its role, though simple, demands an understanding of material science, engineering principles, and industry standards. As the silent guardian of structural integrity, the B flat washer upholds the tenets of Experience, Expertise, Authoritativeness, and Trustworthiness, providing peace of mind to engineers and consumers alike.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News