self tapping socket head cap screw

Understanding Self-Tapping Socket Head Cap Screws

In the landscape of fasteners, self-tapping socket head cap screws stand out as vital components in many engineering and construction applications. Combining the features of a cap screw and a self-tapping capability, these fasteners offer versatility, reliability, and ease of use that makes them a favorite among engineers and manufacturers alike.

What Are Self-Tapping Socket Head Cap Screws?

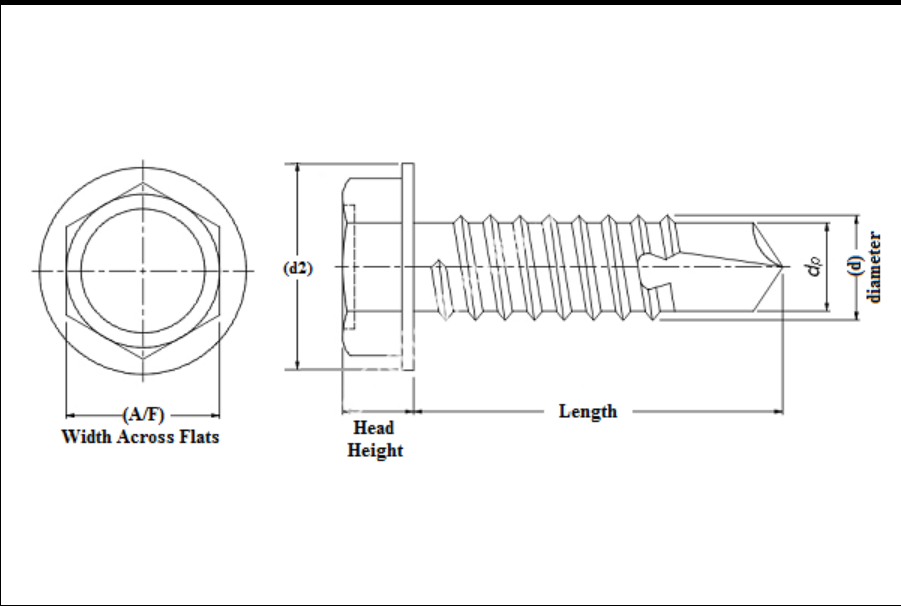

Self-tapping socket head cap screws are specialized screws designed to create their own mating threads in the material they are driven into. The socket head refers to the hexagonal recess in the head of the screw, allowing it to be driven with an Allen wrench or a hex key. Their design enables them to provide a strong grip and reduces the risk of stripping, thus ensuring a secure connection.

These screws are made from various materials, including stainless steel and alloy steel, which provide excellent resistance to corrosion and high tensile strength. They also come in various sizes and lengths, making them suitable for a wide range of applications.

The Benefits of Self-Tapping Socket Head Cap Screws

1. Ease of Use One of the most significant advantages of self-tapping screws is their ease of installation. They do not require a pre-drilled hole, allowing for quick assembly and reducing labor costs. This feature makes them ideal for projects requiring quick turnaround times.

2. Strong Engagement The self-tapping action allows these screws to cut threads directly into the material, resulting in strong engagement with minimal risk of slip. This is especially crucial in applications subjected to vibrations and torque, such as automotive and machinery assembly.

3. Versatility These screws can be used in various materials, including plastics, wood, and metal, making them versatile across different industries. From furniture assembly to heavy machinery, their application is vast.

self tapping socket head cap screw

4. Space-Saving Design The socket head design allows for a lower profile than conventional screws, which can save space and reduce the overall weight of assemblies. This characteristic is critical in applications where weight is a concern, such as aerospace engineering.

5. Aesthetic Appeal The neat appearance of socket head cap screws can enhance the overall look of a finished product, making them popular in consumer electronics and furniture where aesthetics are crucial.

Applications

Self-tapping socket head cap screws are utilized in various industries, including automotive, aerospace, electronics, and construction. In the automotive sector, they are often used to secure components such as engine parts, body panels, and interior fixtures. In aerospace, their weight-saving properties and strength make them ideal for aircraft assembly, where safety and performance are paramount.

In the electronics industry, these fasteners are commonly found in devices where reliable assembly is necessary. Additionally, they are used in furniture manufacturing, providing a robust fastening solution with an aesthetically pleasing appearance.

Installation Tips

Despite their ease of use, there are some best practices to consider during installation - Pre-Drilling For harder materials, a small pilot hole may help guide the screw and reduce the risk of material damage. - Proper Torque Using the correct torque is essential to avoid over-tightening, which can strip the threads or damage the material. - Selecting the Right Size Always match the screw size with the material thickness and type to ensure optimal engagement.

Conclusion

Self-tapping socket head cap screws are exceptional fasteners offering convenience and reliability in diverse applications. Their ability to create self-threads, coupled with their strength and versatility, makes them indispensable in many engineering scenarios. As industries continue to evolve and demand innovative solutions, self-tapping socket head cap screws will undoubtedly remain a staple in fastener technology. Whether for a small DIY project or a complex industrial application, these screws are a powerful tool in any engineer's arsenal.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024